Computer-Controlled Tensile Strength Testing Equipment

Advances in Computer-Controlled Tensile Strength Testing Equipment

In the realm of material science and engineering, understanding the tensile strength of materials is crucial for ensuring their reliability and performance in various applications. Computer-controlled tensile strength testing equipment has revolutionized the way engineers and researchers assess the mechanical properties of materials, providing enhanced precision, efficiency, and data management capabilities.

Tensile strength testing involves measuring a material’s resistance to deformation when subjected to pulling forces. Traditionally, this process was performed using manual machines that required skilled personnel to operate. However, advancements in technology have led to the development of computer-controlled systems that automate the testing process. These modern systems utilize sophisticated software to manage test protocols, machine calibration, and data analysis, significantly reducing the potential for human error.

One of the key advantages of computer-controlled tensile strength testing equipment is its ability to deliver highly consistent results. Automated testing ensures that each specimen is subjected to the same conditions, making comparisons more reliable. Moreover, the integration of advanced sensors and load cells allows for real-time monitoring of stress and strain, providing immediate feedback on the material’s performance.

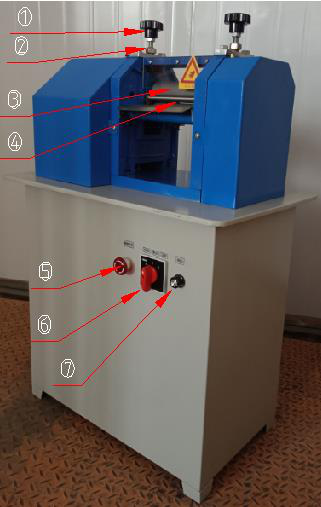

computer control tensile strength testing equipment

Another noteworthy feature is the capacity for large-scale data collection and analysis. Computer-controlled systems can store extensive amounts of test data, enabling engineers to conduct comprehensive analyses and generate detailed reports. This is especially beneficial in research and development settings, where understanding material behavior under various conditions is essential. By utilizing software that implements statistical analysis, users can derive insights that drive innovation in material design and application.

Furthermore, these testing systems can easily adapt to different materials and thicknesses, making them suitable for a wide range of industries, from aerospace to automotive and construction. The user-friendly interfaces of modern tensile testing machines allow for seamless adjustments and customized testing parameters tailored to specific materials and industry standards.

In conclusion, computer-controlled tensile strength testing equipment has dramatically enhanced the accuracy and efficiency of material testing. By minimizing human error, providing comprehensive data management, and accommodating diverse material types, these advanced systems empower engineers to make informed decisions about material selection and application. As technology continues to evolve, we can expect further improvements and innovations in tensile strength testing, ultimately leading to safer and more reliable products in the marketplace.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy