custom insulation resistance tests

Custom Insulation Resistance Tests Ensuring Reliability in Electrical Systems

In an increasingly electrified world, the importance of insulation resistance testing has become paramount. These tests are crucial for ensuring that electrical systems function safely and reliably, preventing failures that could lead to significant downtime or, in the worst cases, catastrophic accidents. Custom insulation resistance tests tailor the evaluation process to the specific needs of a project, enhancing the reliability of electrical installations.

Understanding Insulation Resistance Testing

Insulation resistance tests measure the ability of an insulating material to resist electrical current. High insulation resistance values indicate that the insulating material is doing its job effectively, preventing stray currents that could damage equipment or pose safety hazards. These tests are typically conducted using a megohmmeter, which applies a high voltage to the insulation and measures the resulting current that flows through it.

The result is reported in megohms, with higher values indicating better insulation quality. Standards such as IEEE 43 or IEC 60664 provide benchmarks for acceptable insulation resistance levels, ensuring that testing protocols align with industry norms.

The Need for Customization

While standard testing methods are effective, various applications may require a more tailored approach. Custom insulation resistance tests are designed considering the unique characteristics of specific environments and equipment. Factors such as temperature, humidity, and operational voltages can all influence insulation performance. By customizing test parameters, engineers can deliver more relevant insights, ensuring that testing results accurately reflect the performance of the insulation under the expected operating conditions.

Factors Influencing Custom Tests

Several factors influence the design of custom insulation resistance tests

1. Environmental Conditions Different environments can significantly affect insulation performance. For instance, high humidity levels can lower insulation resistance values, making it essential to consider local climate conditions during testing.

custom insulation resistance tests

2. Equipment Specifications Electrical devices may have varying voltage levels, frequency ranges, and material compositions. Custom tests can incorporate these specifications to ensure the insulation meets the required performance standards.

3. Regulatory Compliance Different industries have specific regulatory standards related to safety and performance. Custom tests can help ensure that insulation resistance levels conform to applicable regulations.

4. Historical Performance Data If an organization has historical data on insulation failures, these insights can be applied to customize tests further, focusing on known problem areas that require closer scrutiny.

5. Lifecycle Stage The stage of an asset’s lifecycle may also dictate the testing approach. For example, new installations may benefit from comprehensive baseline tests, while aging equipment might require more frequent monitoring to detect degradation over time.

Benefits of Custom Insulation Resistance Tests

Implementing custom insulation resistance tests offers several benefits

- Enhanced Safety By identifying weaknesses in insulation earlier, companies can prevent potential failures that could lead to accidents or costly repairs. - Increased Reliability Tailored testing protocols ensure that insulation withstands specific operational conditions, enhancing the reliability of electrical systems. - Cost Savings By pinpointing insulation issues before they escalate, organizations can save money on unscheduled maintenance and lost productivity.

- Improved Longevity Regular, customized testing can inform maintenance strategies that prolong the lifespan of electrical equipment, reducing overall lifecycle costs.

Conclusion

In conclusion, custom insulation resistance tests play a crucial role in the maintenance and reliability of electrical systems. By considering environmental factors, equipment specifications, and historical data, engineers can create targeted testing protocols that yield actionable insights. As our reliance on electrical systems continues to grow, investing in tailored insulation resistance testing will be an essential practice for ensuring operational safety and efficiency in various industries. Embracing this proactive approach will ultimately safeguard investments and enhance the long-term performance of electrical installations.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

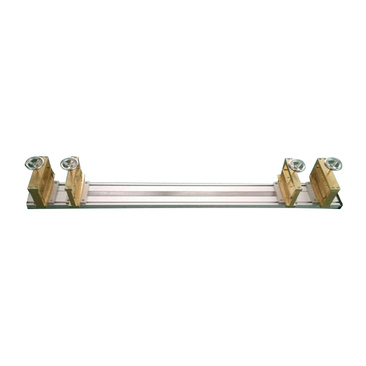

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy