machine to measure resistances factory

The Evolution of Machines to Measure Resistances A Journey Through Precision and Innovation

In the realm of electrical engineering and physics, measuring resistance is a fundamental task that underpins a vast array of applications, from simple circuit design to complex manufacturing processes. The evolution of machines designed specifically to measure resistances has seen remarkable advancements, transforming the landscape of both industry and research.

Historically, the measurement of resistance was a laborious process. Early engineers and scientists used basic tools such as the Wheatstone bridge, a clever circuit that allowed for accurate resistance measurement by comparing an unknown resistance with known values. While effective, this method required careful manual calculations and was often subject to human error. As the demand for precision grew, so too did the need for machines that could automate and streamline this process.

The Evolution of Machines to Measure Resistances A Journey Through Precision and Innovation

As technology progressed, manufacturers began to develop more specialized instruments designed specifically for measuring resistance in a variety of contexts. For instance, micro-ohmmeters emerged to precisely measure very low resistances, crucial in applications such as connector testing and the evaluation of electrical connections. These machines employed sophisticated techniques such as four-wire sensing to eliminate the impact of lead and contact resistance, ensuring accurate readings even in challenging environments.

machine to measure resistances factory

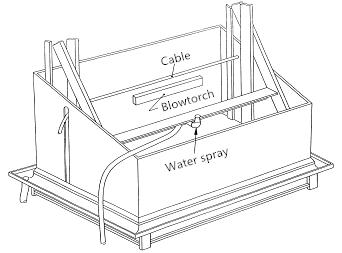

With the rise of automation and smart technologies in the 21st century, machine-based resistance measurement underwent yet another transformation. Automated test systems, which could measure resistances as part of a larger testing suite, began to appear in factories. These systems incorporated advanced software that enabled real-time data analysis, helping to identify inefficiencies and maintain quality standards in manufacturing processes. Not only did this increase measurement reliability, but it also facilitated the integration of resistance measurement into the broader context of production management and optimization.

The advent of wireless technology has further propelled resistance measurement into a new era. Modern resistance measurement devices can now connect to smartphones and cloud-based applications, allowing for remote monitoring and control. This capability enables engineers and technicians to collect and analyze data from anywhere, streamlining workflows and enhancing collaboration across teams.

Moreover, the demand for sustainability and energy efficiency in various sectors has emphasized the importance of accurate resistance measurement. By optimizing resistance values in electrical components, manufacturers can enhance energy efficiency, reduce waste, and improve overall product performance. As a result, the machines designed for resistance measurement have evolved to meet these newer demands, incorporating features that allow for environmental compliance and long-term sustainability initiatives.

Looking to the future, one can anticipate continued advancements in resistance measurement technology. As materials science evolves, and novel materials with unique electrical properties emerge, the need for even more precise and adaptable measurement solutions will grow. The integration of artificial intelligence and machine learning into measurement systems may allow for predictive analytics, whereby machines not only measure resistances but also predict potential failures based on historical data patterns.

In conclusion, the journey of machines designed to measure resistances reflects a broader narrative of technological progress and innovation. From analog devices requiring meticulous manual input to sophisticated automated systems equipped with advanced connectivity features, the transformation highlights not only the increasing demand for precision but also the growing complexity of electrical systems in our modern world. As we move forward, these machines will continue to play a pivotal role in the advancement of technology, ensuring that resistance measurement remains accurate, efficient, and essential to the great tapestry of engineering and technology.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy