manual tensile tester machine factories

Manual Tensile Tester Machines An Overview of Factories and Their Importance

In the world of materials testing, the manual tensile tester machine plays a pivotal role in determining the mechanical properties of various materials. These devices are essential for quality control in manufacturing processes across various industries, including construction, automotive, and aerospace. This article explores the significance of manual tensile tester machines, their functionality, and the factories that produce them.

Understanding Manual Tensile Tester Machines

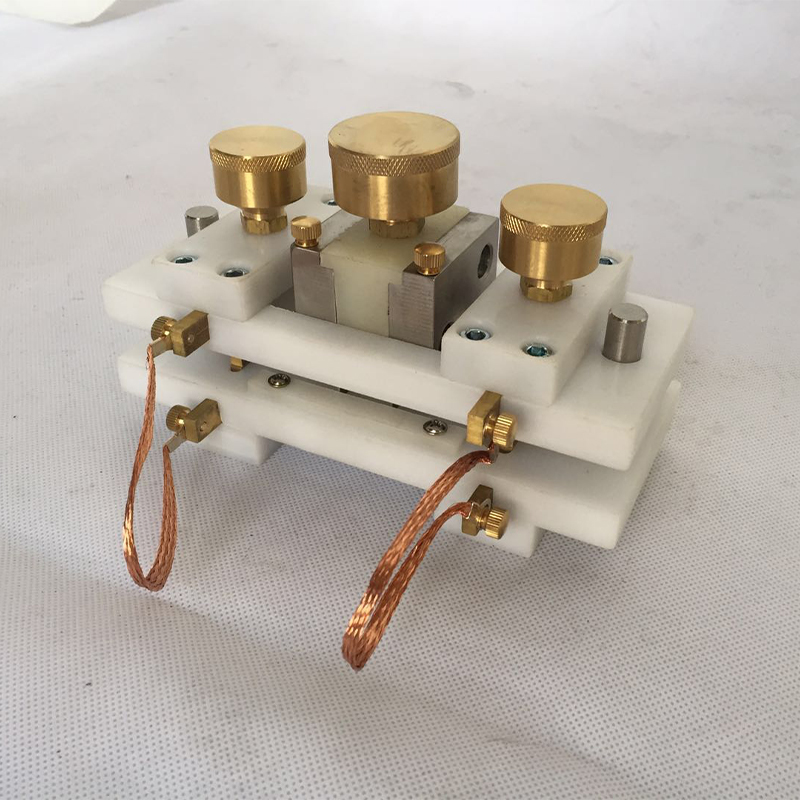

A manual tensile tester machine is designed to evaluate the tensile strength of materials. This is achieved by applying a gradual pulling force to a test specimen until it fractures. The results provide valuable information about the material's elasticity, yield strength, and ultimate tensile strength. Such data is crucial for engineers and designers in ensuring that materials meet required specifications and standards for safety and performance.

The manual aspect of these machines allows for greater control during testing. Operators can adjust the load and rate of pulling, making it possible to conduct more detailed evaluations. This flexibility is particularly beneficial when testing small batches or a wide variety of materials, such as metals, plastics, and textiles.

Essential Features of Manual Tensile Tester Machines

Factories that manufacture manual tensile tester machines incorporate several essential features to ensure accuracy and reliability. Firstly, precision load cells are often integrated into these machines, providing accurate readings of the applied force. Additionally, the testing units are equipped with grips that securely hold the specimen in place, preventing slippage during testing.

Many models also include a dial gauge or digital display that allows operators to monitor elongation and other critical measurements in real time. Some advanced models offer data logging capabilities, which enable the storage and analysis of test results for future reference.

The Role of Factories

manual tensile tester machine factories

The production of manual tensile tester machines is carried out by specialized factories that focus on engineering and manufacturing testing equipment. These factories employ skilled technicians and engineers who understand the nuances of materials science and mechanical engineering.

Quality control is a crucial aspect of manufacturing these devices. Factories conduct rigorous testing on their products to ensure they meet international standards, such as ASTM and ISO. This commitment to quality ensures that the machines produced are not only reliable but also safe for operators.

Furthermore, many factories invest in research and development to innovate and improve their product offerings. As materials and industries evolve, the demand for more sophisticated testing equipment grows. Factories that stay ahead in this regard often lead the market, providing enhanced features and better functionality in their manual tensile tester machines.

The Importance of Manual Tensile Tester Machines in Industry

The significance of manual tensile tester machines cannot be overstated. They serve as a benchmark for assessing material properties, ensuring that manufacturers select appropriate materials for their products. For example, in the construction sector, knowing the tensile strength of steel cables can be crucial for safety in buildings and bridges.

Moreover, these machines support compliance with regulatory requirements. Many industries are mandated to adhere to strict safety and quality standards, which necessitate comprehensive testing of materials. Utilizing a manual tensile tester machine helps companies maintain compliance, avoid costly recalls, and sustain their reputations in the market.

Conclusion

In summary, manual tensile tester machines are a cornerstone in the fields of materials testing and quality assurance. Their production in specialized factories ensures that industries have access to reliable and precise testing equipment. As technology continues to advance, these machines will likely undergo further enhancements, solidifying their status as an essential tool for ensuring the safety and integrity of materials across various applications.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy