wire repeated bending test machine exporters

The Importance of Wire Repeated Bending Test Machines in Quality Control

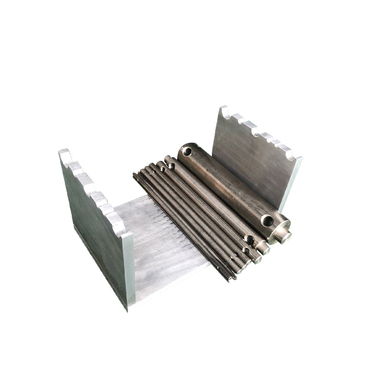

In the realm of manufacturing and material testing, wire repeated bending test machines play a crucial role in ensuring the durability and reliability of metal wires and components. These specialized machines are designed to assess the fatigue resistance of wire materials by simulating repeated bending cycles. This test is essential for industries such as automotive, aerospace, and construction, where the integrity of wire components directly impacts safety and performance.

Wire repeated bending test machines function by clamping a wire at both ends and subjecting it to a series of programmed bends. The number of cycles, angle of bend, and other parameters can be adjusted to meet specific testing standards. Manufacturers use these machines to replicate the stresses that wires will encounter in real-world applications, ensuring that they can withstand the rigors of their intended use. The data gathered from these tests helps engineers improve product designs and select the appropriate materials that will endure over time.

Exporters of wire repeated bending test machines are pivotal in facilitating global quality assurance standards. As manufacturing processes become increasingly globalized, the need for robust testing equipment is more acute than ever. Countries with booming industries, particularly those focused on automotive and aerospace manufacturing, rely heavily on advanced testing equipment to maintain compliance with international standards such as ISO and ASTM.

wire repeated bending test machine exporters

The growing market for wire bending test machines has led to increased competition among manufacturers, pushing for innovation and enhancement in machine capabilities. Many exporters now offer machines with digital interfaces, data logging, and real-time monitoring features that make testing more efficient and accurate. Additionally, customization options allow manufacturers to tailor machines to specific testing requirements, making them versatile for various applications.

When considering the procurement of a wire repeated bending test machine, it’s essential for companies to evaluate potential exporters based on their technical expertise, after-sales support, and adaptability to specific testing needs. Investing in a high-quality bending test machine not only helps in achieving product excellence but also boosts the manufacturer's reputation in a competitive market.

In conclusion, wire repeated bending test machines are indispensable tools in the quality control processes across multiple industries. Their role in ensuring the reliability of wire products cannot be overstated, and as the demand for such machines continues to grow, exporters will play a crucial role in supporting manufacturers in maintaining high standards of quality.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy