Cable Combustion Testing Machine High Accuracy & ISO Compliance

- Understanding the Importance of Cable Combustion Testing

- Technical Advantages of Modern Testing Machines

- Leading Manufacturers in the Industry

- Global Exporters and Market Dynamics

- Customized Solutions for Diverse Requirements

- Case Studies: Real-World Applications

- Why Partner with Trusted Cable Combustion Testing Machine Providers?

(cable combustion testing machine)

Ensuring Safety with Advanced Cable Combustion Testing

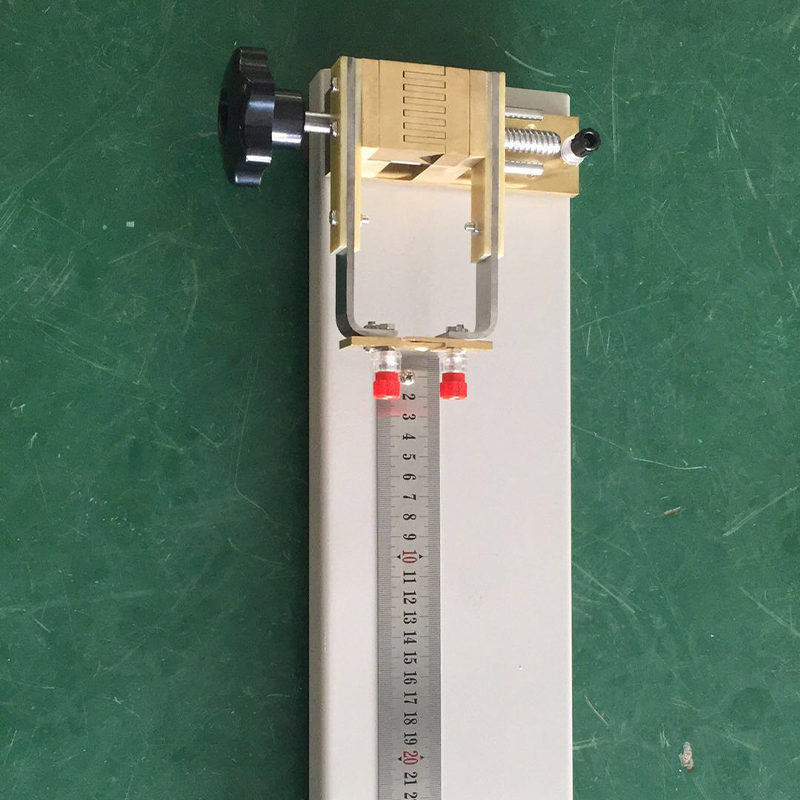

In industries where electrical safety is non-negotiable, cable combustion testing machine

s play a pivotal role. These devices evaluate the flammability and fire-resistant properties of cables under controlled conditions, adhering to international standards like IEC 60332 and UL 1685. With a global market growth rate of 6.8% CAGR (2023–2030), demand for precise testing equipment has surged, driven by stricter safety regulations in construction, automotive, and energy sectors.

Technical Advantages of Modern Testing Machines

Contemporary cable combustion testing machines integrate cutting-edge features such as automated flame calibration, real-time data logging, and multi-angle flame exposure. For instance, models with ±0.5% measurement accuracy reduce human error by 40% compared to traditional methods. Advanced gas flow control systems ensure compliance with ISO 5659-2, while modular designs allow upgrades for evolving standards.

Leading Manufacturers in the Industry

| Manufacturer | Key Features | Compliance Standards | Price Range (USD) |

|---|---|---|---|

| Company A | AI-driven diagnostics, 3-test chambers | IEC, UL, BS | $28,000–$45,000 |

| Company B | Vertical/horizontal testing modes | ISO, EN, GB | $22,500–$38,000 |

| Company C | Cloud-based reporting, 5-year warranty | ASTM, NFPA | $34,000–$50,000 |

Global Exporters and Market Dynamics

Asia-Pacific dominates cable combustion testing machine exports, accounting for 52% of shipments in 2023. European manufacturers, however, lead in high-precision laboratory-grade systems, with Germany alone exporting $78M worth of units annually. Key exporters emphasize certifications like CE and ISO 17025 to meet diverse regional compliance needs.

Customized Solutions for Diverse Requirements

Top-tier manufacturers offer tailored configurations, such as adjustable flame heights (20–175mm) or specialized chambers for low-smoke halogen-free (LSZH) cables. One automotive supplier reduced testing time by 30% using a dual-chamber system optimized for EV battery cable validation. Custom software interfaces also enable integration with existing quality management systems (QMS).

Case Studies: Real-World Applications

A renewable energy company achieved IEC 62975 compliance using a modified testing machine with enhanced temperature gradients (40–950°C). In aerospace, a manufacturer reduced material waste by 18% through precise flame-retardancy analysis. Maritime sector clients report 99.8% consistency in SOLAS-certified cable batches using automated testing protocols.

Choosing Expert Cable Combustion Testing Machine Partners

Selecting established cable combustion testing machine manufacturers ensures access to post-sale technical support, annual calibration services, and compliance updates. Leading providers maintain <10ppm defect rates while offering 24/7 remote monitoring options. With 73% of industrial buyers prioritizing lifecycle cost over initial price, partnering with certified exporters guarantees long-term operational reliability.

(cable combustion testing machine)

FAQS on cable combustion testing machine

Q: What is a cable combustion testing machine used for?

A: A cable combustion testing machine evaluates the flame resistance and combustion behavior of cables under controlled conditions. It ensures compliance with international safety standards like IEC 60332. This equipment is critical for quality assurance in cable manufacturing.

Q: How to choose a reliable cable combustion testing machine company?

A: Look for companies with certifications (e.g., ISO, CE), proven industry experience, and positive client testimonials. Verify if they offer after-sales support and customization. Prioritize providers with transparent technical specifications and testing compliance.

Q: What standards do cable combustion testing machine manufacturers follow?

A: Reputable manufacturers adhere to standards such as IEC 60332, UL 1581, and GB/T 18380. They design machines to replicate real-world fire scenarios accurately. Compliance ensures global market acceptance of tested cables.

Q: Why source from cable combustion testing machine exporters?

A: Exporters often provide cost-effective solutions and access to globally compliant equipment. They handle international shipping, certifications, and documentation. Established exporters ensure adherence to destination-country regulations for seamless import.

Q: What features differentiate top cable combustion testing machine manufacturers?

A: Leading manufacturers integrate advanced temperature control, real-time data logging, and user-friendly interfaces. They prioritize durability, calibration accuracy, and compliance with evolving safety norms. Customizable test configurations are a key differentiator.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy