sij . 14, 2025 10:58

Back to list

cable cross-linked equipment company

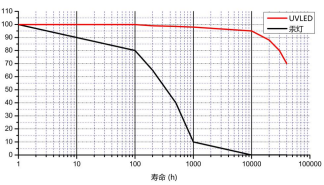

UV irradiation cross-linked equipment stands at the forefront of technological innovation, redefining the standards of material processing and offering unprecedented reliability and efficiency. As industries increasingly seek methods that enhance durability and performance, this equipment has emerged as an indispensable tool across various sectors.

Trustworthiness in the deployment of this equipment is paramount, given its role in critical applications. Manufacturers prioritize rigorous testing and quality assurance processes to ensure device reliability and consistent performance. Many adhere to international standards and obtain certifications to build trust with users. Additionally, customer testimonials and case studies often highlight the equipment's long-term benefits, such as minimized material failure and maintenance costs, contributing to an ROI that aligns with strategic industrial objectives. The adoption of UV irradiation cross-linked equipment in product manufacturing not only fulfills current industry needs but also anticipates future demands for enhanced material capabilities. Industries focusing on lightweight yet powerful material solutions appreciate the unique qualities introduced by UV cross-linking, such as improved tensile strength and weatherability. In summary, UV irradiation cross-linked equipment represents a synthesis of innovation and dependability. As it continues to be embraced by diverse sectors, it inherently bolsters product performance while addressing efficiency and sustainability concerns. The collaborative efforts of scientists and engineers in refining this technology promise its ongoing evolution and expanded utility, affirming its position as a cornerstone of modern material processing methodologies.

Trustworthiness in the deployment of this equipment is paramount, given its role in critical applications. Manufacturers prioritize rigorous testing and quality assurance processes to ensure device reliability and consistent performance. Many adhere to international standards and obtain certifications to build trust with users. Additionally, customer testimonials and case studies often highlight the equipment's long-term benefits, such as minimized material failure and maintenance costs, contributing to an ROI that aligns with strategic industrial objectives. The adoption of UV irradiation cross-linked equipment in product manufacturing not only fulfills current industry needs but also anticipates future demands for enhanced material capabilities. Industries focusing on lightweight yet powerful material solutions appreciate the unique qualities introduced by UV cross-linking, such as improved tensile strength and weatherability. In summary, UV irradiation cross-linked equipment represents a synthesis of innovation and dependability. As it continues to be embraced by diverse sectors, it inherently bolsters product performance while addressing efficiency and sustainability concerns. The collaborative efforts of scientists and engineers in refining this technology promise its ongoing evolution and expanded utility, affirming its position as a cornerstone of modern material processing methodologies.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy