Electromechanical Universal Tensile Testing Machine Manufacturer and Supplier Solutions

The Evolution and Importance of Electromechanical Universal Tensile Testers in Material Testing

The field of materials science has witnessed significant advancements in testing technology, with the electromechanical universal tensile tester standing out as a critical tool for assessing the mechanical properties of various materials. This sophisticated piece of equipment plays a vital role in research and industrial applications, ensuring the integrity and reliability of materials used across different sectors.

Understanding Electromechanical Universal Tensile Testers

Electromechanical universal tensile testers are designed to measure the tensile strength, compressive strength, and other mechanical properties of materials. Utilizing electric motors and precise control systems, these testers can apply controlled loads to a specimen, documenting its response in real-time. This data is crucial for understanding how materials behave under various forces, which is essential for quality control, product development, and research purposes.

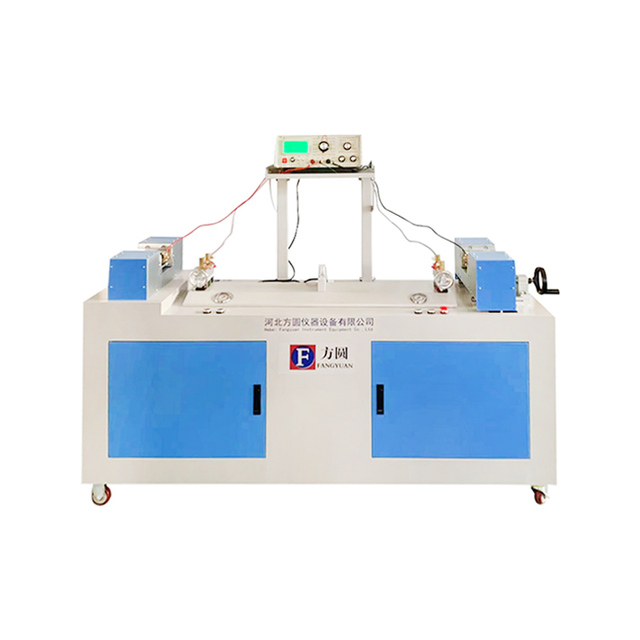

The primary components of an electromechanical universal tensile tester include a test frame, load cell, actuator, and a software interface. The test frame provides the necessary structure to hold the specimen securely, while the load cell measures the amount of force being applied. The actuator, typically powered by an electric motor, moves the grips of the tester to apply the tensile or compressive force. Finally, the software interface allows users to program tests, monitor real-time data, and analyze results efficiently.

Key Features and Advantages

Electromechanical universal tensile testers are renowned for their precision and versatility. One of the key advantages is the ability to perform a wide range of tests on various materials, including metals, plastics, composites, and textiles. By simply changing the grips and fixtures, users can adapt the tester to accommodate different sample shapes and sizes, making it a highly flexible solution for materials testing.

Another significant benefit is the high level of accuracy these testers provide. The integration of advanced load cells and actuators ensures that measurements are both reliable and repeatable. Engineers and researchers often require precise data to make informed decisions, and the electromechanical universal tensile tester delivers consistent results, thereby enhancing the reliability of material evaluations.

Applications Across Industries

electromechanical universal tensile tester factory

The applications of electromechanical universal tensile testers span several industries, including aerospace, automotive, construction, and manufacturing. In the aerospace industry, materials must withstand extreme conditions, and rigorous testing is essential to ensure safety and performance. Tensile testers are used to evaluate the strength and ductility of aluminum alloys and composites, which are commonly used in aircraft structures.

Similarly, the automotive sector relies heavily on tensile testing to assess the performance of materials used in vehicle components. From body panels to safety features, understanding the mechanical properties of materials helps manufacturers design safer, lighter, and more efficient vehicles.

In construction, the integrity of materials such as concrete and steel is paramount. Universal tensile testers are employed to test the tensile strength of reinforcing bars and other materials used in building structures, ensuring compliance with safety regulations and industry standards.

Future Prospects and Innovations

As technology continues to evolve, so too do the capabilities of electromechanical universal tensile testers. Innovations in digital data acquisition, automation, and even artificial intelligence are paving the way for more advanced testing systems. These improvements promise to streamline the testing process, reduce human error, and provide even more detailed insights into material behavior.

The integration of smart technology into tensile testing equipment could lead to real-time data analysis and remote monitoring. This advancement would be particularly beneficial in large-scale manufacturing environments, where speed and efficiency are crucial. Additionally, the development of environmentally-friendly testing methods and materials is likely to become a focus for manufacturers in response to growing sustainability concerns.

Conclusion

In summary, electromechanical universal tensile testers are indispensable tools in the world of materials testing. Their precision, versatility, and ability to deliver reliable data make them essential for industries that prioritize quality and safety. As technology progresses, these testers will undoubtedly become even more sophisticated, enhancing our ability to understand and manipulate materials in innovative ways. Whether in aerospace, automotive, construction, or manufacturing, the impact of tensile testing on product development and safety will continue to be profound, shaping the future of engineering and design.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy