Manufacturer of High-Precision Equipment for Measuring Conductor Resistance in Electrical Applications

The Importance of Conductor Resistance Measurement Machines and Their Manufacturers

In the realm of electrical engineering, the measurement of conductor resistance is crucial for ensuring the reliability and efficiency of electrical systems. The performance of electrical apparatus, from high-voltage power lines to intricate circuit boards, heavily depends on the resistance of conductors used within them. Consequently, the role of conductor resistance measurement machines and their manufacturers is of paramount importance in both industrial and laboratory settings.

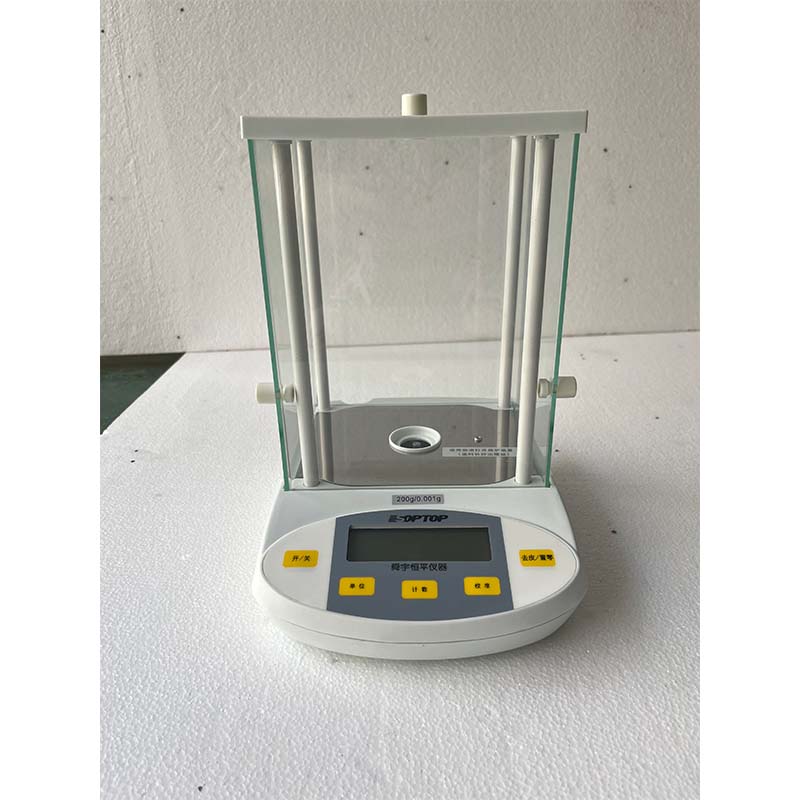

Conductor resistance measurement machines are specialized devices designed to measure the resistance of various types of electrical conductors. These machines employ precise methodologies to ensure accurate readings, which are essential for safety, efficiency, and compliance with regulatory standards. A variety of factors, including temperature, material composition, and conductor length, can influence resistance measurements. Thus, having a reliable measurement apparatus is critical.

Manufacturers of these machines draw upon advanced technology and innovative design principles to develop tools that meet diverse user requirements. From traditional analog devices to cutting-edge digital meters equipped with microprocessors, modern conductor resistance measurement machines are designed to offer high accuracy, usability, and advanced features such as data logging and wireless connectivity.

One of the primary challenges faced by manufacturers is the need to balance accuracy with ease of use. Modern machines must not only provide precise resistance measurements but also be user-friendly for technicians who may not have extensive training in electrical measurement technology. Consequently, leading manufacturers invest in user interface design, making it intuitive and straightforward to navigate through various functionalities.

conductor resistance measurement machine manufacturer

Another critical aspect involves calibration and standards compliance. Conductor resistance measurement machines must adhere to international standards to ensure the credibility of the measurements taken. Manufacturers must implement stringent quality control measures and regular calibration procedures to maintain the accuracy of their devices. As technology evolves, manufacturers also integrate features that facilitate ease of calibration, enhancing reliability and user trust in the equipment.

Furthermore, the materials used in the construction of these machines also play a significant role in their performance. Manufacturers are increasingly utilizing durable, lightweight materials that enhance the portability of the devices without compromising their robustness. This is especially important in field testing scenarios where equipment needs to be transported to different locations.

The rise of automation and smart technology is revolutionizing how conductor resistance is measured. Leading manufacturers are incorporating features like remote monitoring, real-time data analysis, and cloud storage capabilities into their machines. This allows users to conduct tests efficiently and analyze results without being physically present, thus optimizing workflow in environments such as electrical maintenance and testing services.

Sustainability is another growing concern in the manufacturing sector. As environmental awareness increases, manufacturers are exploring ways to reduce the ecological impact of their production processes and create energy-efficient devices. This trend not only appeals to environmentally conscious consumers but also aligns with global efforts towards sustainable development.

In conclusion, the significance of conductor resistance measurement machines and their manufacturers cannot be overstated. These devices are essential in ensuring the integrity and safety of electrical systems, making them a critical component in industries ranging from construction to telecommunications. As technology continues to advance, machine manufacturers must stay ahead of the curve by integrating innovative features, ensuring reliability through rigorous testing, and addressing environmental concerns. The future of conductor resistance measurement lies in the hands of visionary manufacturers who prioritize quality, technology, and sustainability.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy