tensile yield tester factory

Exploring the Significance of Tensile Yield Tester Factories in Material Testing

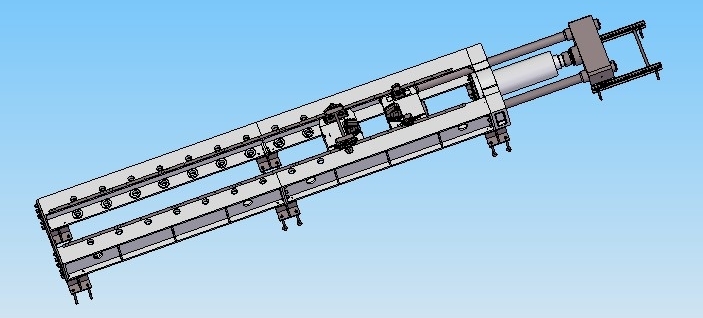

In the world of materials science and engineering, the evaluation of material properties is fundamental to ensuring safety, reliability, and performance in various applications. One of the key instruments utilized in this evaluation is the tensile yield tester, a device designed to measure the tensile strength and yield properties of materials. The factories that manufacture these testers play a crucial role in the advancement of materials testing technology, contributing to countless industries ranging from construction to aerospace.

The Role of Tensile Yield Testers

Tensile yield testers are specialized machines used to assess how materials behave under tension. The primary purpose of these devices is to identify the tensile strength, yield strength, and elongation at break of materials. This data is critical for engineers and designers when determining the suitability of materials for specific applications. For instance, in the automotive industry, components must be able to withstand stress without failure. By utilizing tensile yield testers, manufacturers can guarantee that their materials meet stringent safety standards.

The Manufacturing Process

The production of tensile yield testers is a sophisticated process that requires precision engineering and high-quality materials. Factories specializing in these devices typically employ advanced manufacturing techniques to ensure durability and accuracy. The production process often includes design prototyping, extensive testing, and quality control measures to produce reliable machines that can withstand repeated use. Additionally, some factories integrate automation into their production lines, optimizing efficiency and reducing the likelihood of human error.

Importance of Quality Control

Quality control is paramount in the manufacturing of tensile yield testers. Given the critical role these machines play in determining material properties, any defects in manufacturing could lead to erroneous results, potentially causing catastrophic failures in real-world applications. Factories implement rigorous testing protocols to ensure each tensile yield tester meets international standards. This includes calibrating the machines with certified materials, performing repeated tests, and maintaining comprehensive documentation of each unit produced.

tensile yield tester factory

Innovations in Tensile Yield Testing

As technology advances, so do the capabilities of tensile yield testers. Modern factories are investing in research and development to enhance the functionality of their devices. Innovations such as digital interfaces, automated measurement systems, and real-time data analysis software are becoming standard features. These advancements not only improve the user experience but also provide more accurate and comprehensive data, facilitating better decision-making for manufacturers and engineers.

Global Market Dynamics

The demand for high-quality tensile yield testers is growing globally, driven by the increasing need for material testing in various sectors. With the rise of new materials, including composites and advanced alloys, the requirements for testing equipment have become more complex. Factories must stay agile and adapt to evolving market demands, often expanding their product lines to include testers suited for niche applications.

Environmental Considerations

In recent years, there has been a push towards sustainable manufacturing practices, and tensile yield tester factories are no exception. Many manufacturers are now focusing on reducing their environmental footprint by implementing energy-efficient processes and reducing waste. Additionally, the choice of materials used in production is being scrutinized to ensure that they are sourced responsibly and disposed of in an environmentally friendly manner.

Conclusion

Tensile yield tester factories play a vital role in the materials testing industry, producing essential equipment that helps ensure the structural integrity and safety of various materials. As industries evolve and new materials emerge, the importance of these manufacturers will continue to grow. By focusing on quality, innovation, and sustainability, tensile yield tester factories are not only meeting current market demands but also paving the way for future advancements in material science. The ongoing collaboration between manufacturers, researchers, and industries will undoubtedly lead to enhanced testing techniques and technologies, ultimately benefiting the global marketplace.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy