UV Irradiation Crosslinking Equipment Manufacturers and Production Facilities Overview

The Evolution of UV Irradiation Crosslinking Machine Factories

In the rapidly advancing world of manufacturing, UV irradiation crosslinking technology has emerged as a pivotal process in various industries. This technology is particularly prominent in the creation of durable and high-performance materials through the crosslinking of polymers, facilitating enhanced properties such as increased strength, chemical resistance, and thermal stability. As the demand for innovative and efficient production techniques rises, the landscape of factories specializing in UV irradiation crosslinking machines continues to evolve.

UV irradiation crosslinking machines harness ultraviolet light to initiate the polymerization and crosslinking process

. This method eliminates the need for solvents, reducing harmful emissions and creating more environmentally friendly production lines. As a result, factories producing these machines are now adopting eco-conscious practices in their operations, from energy-efficient equipment to sustainable materials sourcing.One of the key factors driving the growth of UV irradiation crosslinking machine factories is the increasing demand for high-quality coatings, adhesives, and sealants across industries such as automotive, aerospace, electronics, and construction. The ability to cure products rapidly with UV light significantly enhances production efficiency. Manufacturers are now focusing on developing machines that can accommodate various sizes and types of substrates, offering flexibility and adaptability to meet the specific needs of different applications.

uv irradiation crosslinking machine factories

Moreover, technological advancements are contributing to the sophistication of UV irradiation crosslinking machinery. Modern factories are integrating automation, data analytics, and IoT (Internet of Things) solutions into their manufacturing processes. This integration allows for real-time monitoring and control of production parameters, leading to improved quality assurance and reduced waste. Factories are increasingly investing in research and development to innovate and optimize their machinery, ensuring they stay competitive in an evolving market.

Safety and compliance are also central to the operations of UV irradiation crosslinking machine factories. As UV technology can pose health risks if not managed correctly, manufacturers are implementing stringent safety protocols and ensuring their machines comply with international standards. This not only protects workers but also instills confidence in customers about the reliability of their products.

In conclusion, UV irradiation crosslinking machine factories are at the forefront of modern manufacturing, driven by technological advancements and the need for sustainable production methods. As industries continue to evolve and demand high-performance materials, these factories are poised for growth, continually refining their processes and products to meet the ever-changing needs of the market. The future of UV irradiation crosslinking technology looks promising, paving the way for innovation and efficiency in manufacturing.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

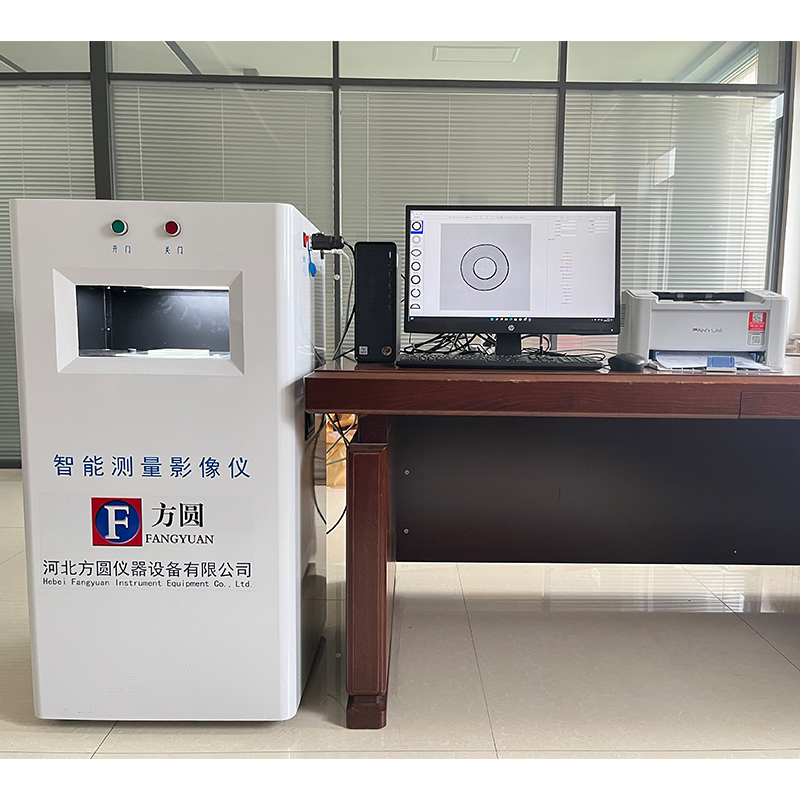

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy