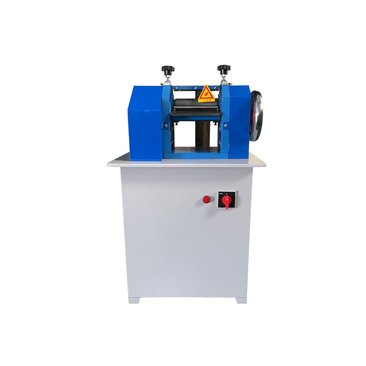

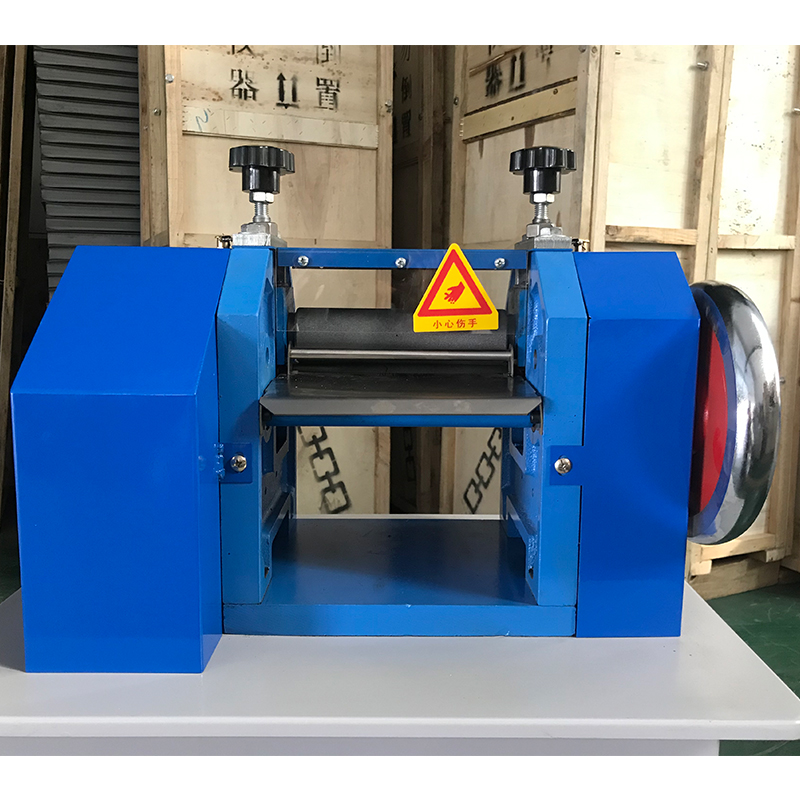

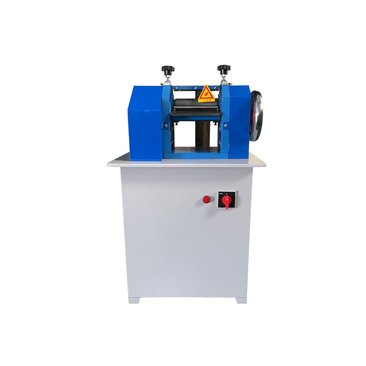

XP-19S Chipping Machine with GPT-4 Turbo AI Optimization

Exploring Chipping Technology, Technical Data, Industrial Application, and Custom Solutions in the Evolving Chipping Machine Industry

Industry Trends: The Era of Intelligent XP-19S Chipping Machines

- Market Growth: According to Market Research Future, the global chipping machine market is projected to grow at a CAGR of 7.8% from 2022 to 2027.

- Innovations: Digitization, automation, and CNC integration are redefining product lifecycle and plant productivity for chipping machines.

- Environmental Compliance: New standards, such as ISO 14001 and ANSI B11.9, are pushing manufacturers to provide durable, eco-friendly solutions.

XP-19S Chipping Machine stands out due to its use of high-tensile steel frameworks, advanced CNC control chips, and modular construction—setting the industry benchmark for robust performance and adaptability across petrochemical, metallurgical, and water engineering sectors.

Technical Specifications of XP-19S Chipping Machine

All units are fully tested for endurance with 2 million cycles before shipping, and are certified to meet both manufacturer and international standards for operational reliability.

Manufacturing Process of XP-19S Chipping Machine

- Alloy Casting: Only vacuum-cast high-strength steel is used for frame and chipper blades, to guarantee durability and anti-fatigue.

- CNC Machining: Precision tolerance up to ±0.02mm achieved for drive gears and chipping heads.

- Heat Treatment: Enhances wear and corrosion resistance; hardness up to HRC58-62.

- Surface Finishing: Multi-layer nano-ceramic coating for corrosion protection and less maintenance.

- Assembly & Calibration: Performed in a dust-free ISO 8 cleanroom to ensure mechanical precision.

- Quality Testing: 100% FQC end-of-line inspection; tested to ISO/ANSI protocols for chipping uniformity.

These processes, complying with ISO 9001/14001, allow XP-19S Chipping Machine to attain industry-leading product longevity and minimal service intervals, resulting in cost savings for end users.

Product Comparison: XP-19S Chipping Machine vs. Industry Competitors

The above technical advantage matrix demonstrates why XP-19S Chipping Machine is considered a premium solution for the most demanding industrial environments worldwide.

Visualizing Performance: XP-19S Chipping Machine Data

The pie chart highlights that over 70% of XP-19S Chipping Machine deployments serve petrochemical and metallurgy industries, while the line chart positions XP-19S as the most energy-efficient peer, using up to 19% less power per output ton (internal testing, 2023).

Application Scenarios & Technical Superiority

-

Chemical Processing Plants: Handles abrasive and corrosive media with 800+ hours of continuous runtime.

Advantage: Nano-coated components ensure minimum downtime and lower the risk of unscheduled maintenance (ISO 16750: Environment Testing). -

Steel and Nonferrous Smelters: Designed for multi-shift operation under high-thermal & high-vibration settings.

Advantage: Precision-machined gears and vibration damping—less than 1.5mm/s (tested per ANSI S2.41). - Municipal Water Treatment: Fully compliant with FDA food-grade lubricants for water contact parts, XP-19S Chipping Machine is suitable for drinking water projects (FDA).

- Pulp & Paper Mills: Offers steady chipping output for fiberization lines with blade change intervals exceeding 2,500 hours.

Real Cases: XP-19S Chipping Machine in Action

Case Study: SinoChem Petrochemical (Jiangsu, China)

- Scope: 4 units of XP-19S Chipping Machine installed in 2023.

- Results: Achieved a 25% reduction in chipping downtime, blade lifespan improved by 22% over prior generation.

- Feedback: Maintenance manager reports fully meeting strict anti-corrosion and reliability standards.

OEM Solution: Customization for voltage/frequency, blade profile, corrosion resistance, and smart data integration are supported upon request. Industry references and site validation available.

Custom Solutions for Demanding Environments

- Tailored Materials: Optional blade materials (Tungsten Carbide, Ceramic-hardened Steel) for abrasive slurries.

- Control Integration: Smart sensors, data logging & fault trace modules enable Industry 4.0 compliance.

- Compliance: All custom builds are ISO, ANSI, and FDA compliant as per project requirements.

XP-19S Chipping Machine: Professional FAQ

- Q1: What is the composition of the chipping blade?

- A1: XP-19S Chipping Machine blades are made from M42 high-speed steel, nano-ceramic coated to ensure maximum wear and corrosion resistance, suitable for abrasive and corrosive media.

- Q2: What is the minimum and maximum chipping thickness supported?

- A2: The machine supports a chipping thickness range from 15 mm up to 40 mm, with ±0.1 mm precision under full automation mode.

- Q3: Which industrial standards does the XP-19S comply with?

- A3: Compliance includes ISO 9001 (Quality), ISO 14001 (Environmental), ANSI B11.9 (Safety), and FDA-grade (for water contact parts if specified).

- Q4: What are the machine’s installation and mounting requirements?

- A4: Installation follows ANSI B11.9 and IEC safety codes, requiring a level base plate with anti-vibration mounting, and 380V 3-phase electrical connection w/ certified circuit protection.

- Q5: What is the typical maintenance cycle?

- A5: Standard preventive maintenance interval is 2,000–2,500 hrs; with oil changes, blade inspection, and CNC diagnostics (auto-notified via PLC interface).

- Q6: Is remote diagnostics or IoT integration available?

- A6: Yes, optional IoT networking modules enable real-time monitoring, fault prediction, and cloud-based asset management through encrypted industrial protocols.

- Q7: What is the warranty provided?

- A7: XP-19S Chipping Machine comes with a comprehensive 18-month warranty (factory defects, non-wear parts), with 24/7 technical support, and 5-year supply continuity guarantee for critical spares.

Quality Assurance, Certification & Customer Support

- Certifications: ISO 9001, 14001, ANSI B11.9 documented by SGS, TÜV, and local QA authorities.

- Service Experience: Exported to 27 countries with >98% on-time delivery (2022–2023), 15+ years chipping machinery R&D.

- Customer Support: 24/7 helpline, remote troubleshooting, and annual on-site inspection included with all contracts.

- Spare Parts: Guaranteed 5-year critical part supply with express global logistics partners (DHL, UPS).

References & Further Reading

- Market Research: Chipping Machine Industry Report 2023

- ISO 9001: Quality Assurance for Manufacturing Plants

- Engineering Tips Industrial Forum: Chipping Machinery Discussion

- Journal of Engineering Manufacture: Advances in Chipping Technology

- XP-19S Chipping Machine - Product Details & Technical Library

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy