Leading Manufacturer of High-Quality Dumbbell Die Cutters for Precision Cutting Solutions

The Rise of Dumbbell Die Cutter Manufacturers A Comprehensive Overview

In the expansive world of manufacturing, where precision meets innovation, dumbbell die cutters have carved a niche for themselves as indispensable tools in various industries. These machines, designed for cutting materials into specific shapes, have gained widespread adoption due to their unique features and capabilities. This article explores the rise of dumbbell die cutter manufacturers, the technology behind these machines, their applications, and their future prospects.

Understanding Dumbbell Die Cutters

Dumbbell die cutters are specialized machines used primarily in processing materials such as paper, plastics, and fabrics. They receive their name from the dumbbell-shaped dies that are used in the cutting process. These dies allow manufacturers to create symmetrical shapes that are essential for many applications, particularly in the fitness industry, where dumbbells are needed for exercise equipment. The manufacturing process involves placing a sheet of material on a cutting bed where the die presses down to create the desired shape.

Advantages of Using Dumbbell Die Cutters

The primary advantage of dumbbell die cutters is their ability to produce high volumes of identical items with remarkable precision. As industries increasingly demand consistency and quality, these machines have become crucial in ensuring that products meet specific standards. Among their other benefits are

1. Speed and Efficiency Dumbbell die cutters can operate at high speeds, significantly reducing production times. This efficiency is vital for industries that require quick turnaround times to meet market demands.

2. Minimized Waste Advanced designs and cutting techniques result in less scrap material, which not only saves costs but also promotes sustainability in manufacturing processes.

3. Versatility Manufacturers can use dumbbell die cutters for a wide range of materials, enabling them to produce various products, from packaging materials to components in automotive manufacturing.

4. Customization Many dumbbell die cutter manufacturers offer customizable dies to suit specific client needs, allowing businesses to create unique products that stand out in the market.

The Manufacturing Landscape

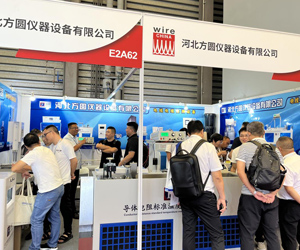

dumbbell die cutter manufacturer

The market for dumbbell die cutters has experienced significant growth over the last decade, driven by technological advancements and a surge in demand from various sectors. Manufacturers have increasingly adopted automation and computer-aided design (CAD) technologies to enhance their production capabilities. These innovations facilitate precision engineering and allow for rapid prototyping, enabling manufacturers to stay ahead of the competition.

Today's leading dumbbell die cutter manufacturers leverage cutting-edge technologies, such as servo motors and PLC (Programmable Logic Controllers), to maximize efficiency and accuracy. These machines can be integrated into larger automated systems, further enhancing production lines and reducing labor costs.

Applications Across Industries

The versatility of dumbbell die cutters has led to their adoption across numerous industries. Some notable applications include

- Fitness Equipment As the health and fitness trend continues to grow, manufacturers of gym equipment use dumbbell die cutters to produce customized weights and exercise accessories.

- Packaging In the packaging sector, these cutters are essential for producing boxes, cardboard cuts, and protective inserts that fit specific products.

- Automotive Parts The automotive industry utilizes dumbbell die cutters to create various components that require precision cuts for assembly and manufacturing.

- Textiles In the fashion and upholstery industries, these machines are used to cut fabric into intricate shapes, allowing for greater creativity in design.

Future Prospects

The future of dumbbell die cutter manufacturing looks promising. As more industries recognize the importance of efficiency and precision, the demand for these machines is likely to increase. Furthermore, the trend towards sustainable manufacturing practices is prompting manufacturers to innovate and adapt to eco-friendly materials and processes.

In conclusion, dumbbell die cutter manufacturers play a pivotal role in the modern manufacturing landscape. Their ability to deliver high-quality, precise products quickly and efficiently makes them essential partners for businesses across diverse sectors. As technology continues to evolve, we can expect these manufacturers to lead the charge in innovation, driving further improvements and new applications for dumbbell die cutters in the global market.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy