jan . 14, 2025 15:45

Back to list

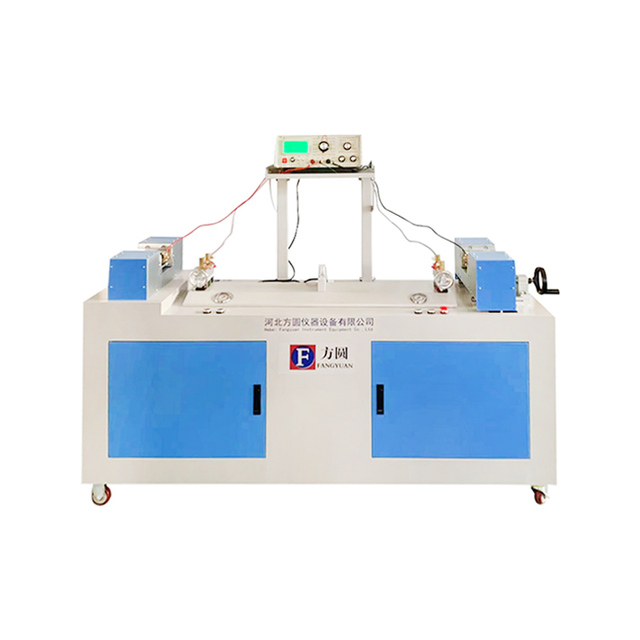

Wire and Cable Smoke Density Test Machine

In the rapidly evolving realm of automated manufacturing, precision is key. The automatic optical measurement machine (AOMM) stands at the forefront of this technological advancement. Offering unparalleled precision and speed, AOMMs are an essential investment for companies aiming to improve their production quality and efficacy. Drawing from extensive industry expertise, this article delves into the operational benefits, cutting-edge features, and strategic advantages of using automatic optical measurement machines in modern manufacturing processes.

Trustworthiness is another critical aspect when considering the implementation of AOMMs. These machines come with rigorous certification standards and are often developed in compliance with international industry regulations. This compliance ensures that companies can rely on these machines to deliver accurate, repeatable, and reliable measurements, fostering a strong foundation of trust with stakeholders, including clients and regulatory bodies. Industry experts and operators alike appreciate the user-friendly interfaces and programmable versatility of modern AOMMs. These machines can be tailored to specific tasks and seamlessly integrated into existing workflows, minimizing disruptions during transitions from manual or semi-automatic measurement systems. Moreover, regular software updates and robust customer support from manufacturers ensure that companies are consistently operating at the cutting edge of technological advancements. In examining the authoritative impact of AOMMs, case studies have documented remarkable enhancements in production metrics. Companies that have integrated these machines report improvements in defect detection rates by up to 30%, alongside a reduction in measurement times by as much as 40%. These statistics not only highlight the superior performance of AOMMs over traditional methods but also emphasize the authoritative role these machines play in setting benchmarks for industry standards. In conclusion, the adoption of automatic optical measurement machines signifies more than a technical upgrade; it represents a strategic commitment to quality, efficiency, and innovation. For companies determined to thrive in today’s precision-driven markets, investing in AOMMs is a decision that aligns with modern manufacturing imperatives and establishes a firm foundation for sustainable growth and competitive advantage.

Trustworthiness is another critical aspect when considering the implementation of AOMMs. These machines come with rigorous certification standards and are often developed in compliance with international industry regulations. This compliance ensures that companies can rely on these machines to deliver accurate, repeatable, and reliable measurements, fostering a strong foundation of trust with stakeholders, including clients and regulatory bodies. Industry experts and operators alike appreciate the user-friendly interfaces and programmable versatility of modern AOMMs. These machines can be tailored to specific tasks and seamlessly integrated into existing workflows, minimizing disruptions during transitions from manual or semi-automatic measurement systems. Moreover, regular software updates and robust customer support from manufacturers ensure that companies are consistently operating at the cutting edge of technological advancements. In examining the authoritative impact of AOMMs, case studies have documented remarkable enhancements in production metrics. Companies that have integrated these machines report improvements in defect detection rates by up to 30%, alongside a reduction in measurement times by as much as 40%. These statistics not only highlight the superior performance of AOMMs over traditional methods but also emphasize the authoritative role these machines play in setting benchmarks for industry standards. In conclusion, the adoption of automatic optical measurement machines signifies more than a technical upgrade; it represents a strategic commitment to quality, efficiency, and innovation. For companies determined to thrive in today’s precision-driven markets, investing in AOMMs is a decision that aligns with modern manufacturing imperatives and establishes a firm foundation for sustainable growth and competitive advantage.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy