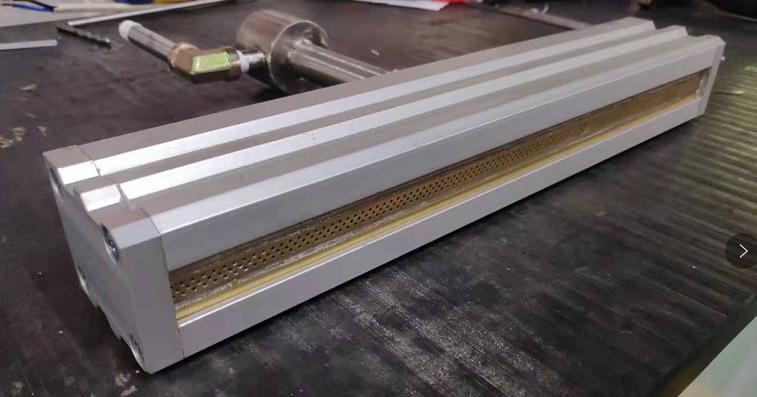

cable bunched combustion test machine factory

The Importance of Cable Bunched Combustion Test Machines in Ensuring Fire Safety

In an age where technology permeates every aspect of our lives, ensuring safety, especially in electrical installations, has never been more critical. One significant piece of equipment that plays a pivotal role in this regard is the cable bunched combustion test machine. This specialized apparatus evaluates the flammability of cable bundles used in various electrical and electronic applications, particularly in industries where safety must be prioritized.

Cable bunched combustion test machines are designed to simulate real-life fire scenarios. They assess how different types of cables react under extreme heat and flame conditions. This is particularly important because cables are often bundled together in installations, which can enhance the risk of fire spread. When one cable ignites, the fire can easily propagate to adjacent cables, leading to extensive damage and potentially catastrophic outcomes. Therefore, manufacturers and regulatory bodies need reliable testing methods to ensure that their products comply with safety standards.

One of the crucial reasons for implementing these testing machines in factory settings is regulatory compliance. Various international and national standards dictate the flammability performance necessary for electrical cables. Organizations like the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) outline specific testing procedures that manufacturers must adhere to. A cable bunched combustion test machine helps manufacturers determine if their products meet these stringent criteria. Failure to comply can lead to serious implications, including legal consequences, financial losses, and damage to reputation.

cable bunched combustion test machine factory

The operation of a cable bunched combustion test machine typically involves placing a sample of bundled cables in a controlled environment and exposing them to flame. The machine measures critical parameters such as ignition time, flame spread, and smoke production. These results are vital for assessing the behavior of cable bundles during a fire and are used to improve product design and manufacturing processes.

Moreover, these machines are essential for innovation in the field of cable manufacturing. As new materials and technologies emerge, testing becomes increasingly important to ensure safety and performance. Manufacturers can utilize data acquired from these tests to enhance their designs, reduce fire hazards, and develop new materials with improved fire-resistant properties.

In addition to protecting lives and property, effective testing can lead to cost savings in the long run. By identifying potential fire risks early in the product development phase, manufacturers can mitigate the risk of costly recalls, repairs, and liability claims. This proactive approach to safety also fosters consumer trust, as customers increasingly seek products that prioritize fire safety.

In conclusion, cable bunched combustion test machines are a crucial investment for manufacturers in the electrical industry. They not only help ensure compliance with safety standards but also drive innovation and protect against potential hazards associated with electrical installations. As our reliance on technology continues to grow, the importance of rigorous testing to safeguard public safety cannot be overstated. The future of cable manufacturing lies in its ability to produce safer, more reliable products, and testing machines play a vital role in achieving that goal.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy