Հնվ . 14, 2025 10:10

Back to list

cable smoke density test machine company

In the intricate realm of material testing and product development, the aging test oven stands as a cornerstone of quality assurance and reliability verification. Designed to simulate the environmental conditions that materials, components, or devices will face during their lifecycle, these ovens are indispensable tools across diverse industries such as electronics, automotive, aerospace, and pharmaceuticals.

Authoritativeness in the aging test oven sector is demonstrated through compliance with international standards and certifications, such as ISO 9001 for quality management and ISO 17025 for testing and calibration laboratories. Leading brands within the industry often align their manufacturing processes with these standards, ensuring their ovens meet the rigorous requirements necessary for global markets. This alignment not only guarantees superior product quality but also reinforces their status as trusted suppliers in the scientific and industrial communities. Trustworthiness is further bolstered by customer testimonials and successful use cases that highlight the ovens' pivotal role in product excellence. Companies looking to invest in aging test ovens are advised to seek out detailed case studies from peers in their industry, which can provide first-hand insights into performance metrics and ROI. Additionally, maintaining an aging test oven in peak condition requires a commitment to regular calibration and maintenance to preserve accuracy and functionality. This attention to upkeep, often backed by manufacturer warranties and service plans, underscores a company's dedication to quality assurance and transparency. In summary, the aging test oven is not just a piece of laboratory equipment; it's a strategic investment in product development and assurance. By providing a controlled environment to study the impacts of time and stress on products, these ovens enable businesses to foster innovation, improve product longevity, and uphold a reputation for excellence. As industries continue to evolve, the role of aging test ovens will only become more pivotal, cementing their place as a key driver in the pursuit of quality and reliability.

Authoritativeness in the aging test oven sector is demonstrated through compliance with international standards and certifications, such as ISO 9001 for quality management and ISO 17025 for testing and calibration laboratories. Leading brands within the industry often align their manufacturing processes with these standards, ensuring their ovens meet the rigorous requirements necessary for global markets. This alignment not only guarantees superior product quality but also reinforces their status as trusted suppliers in the scientific and industrial communities. Trustworthiness is further bolstered by customer testimonials and successful use cases that highlight the ovens' pivotal role in product excellence. Companies looking to invest in aging test ovens are advised to seek out detailed case studies from peers in their industry, which can provide first-hand insights into performance metrics and ROI. Additionally, maintaining an aging test oven in peak condition requires a commitment to regular calibration and maintenance to preserve accuracy and functionality. This attention to upkeep, often backed by manufacturer warranties and service plans, underscores a company's dedication to quality assurance and transparency. In summary, the aging test oven is not just a piece of laboratory equipment; it's a strategic investment in product development and assurance. By providing a controlled environment to study the impacts of time and stress on products, these ovens enable businesses to foster innovation, improve product longevity, and uphold a reputation for excellence. As industries continue to evolve, the role of aging test ovens will only become more pivotal, cementing their place as a key driver in the pursuit of quality and reliability.

Latest news

-

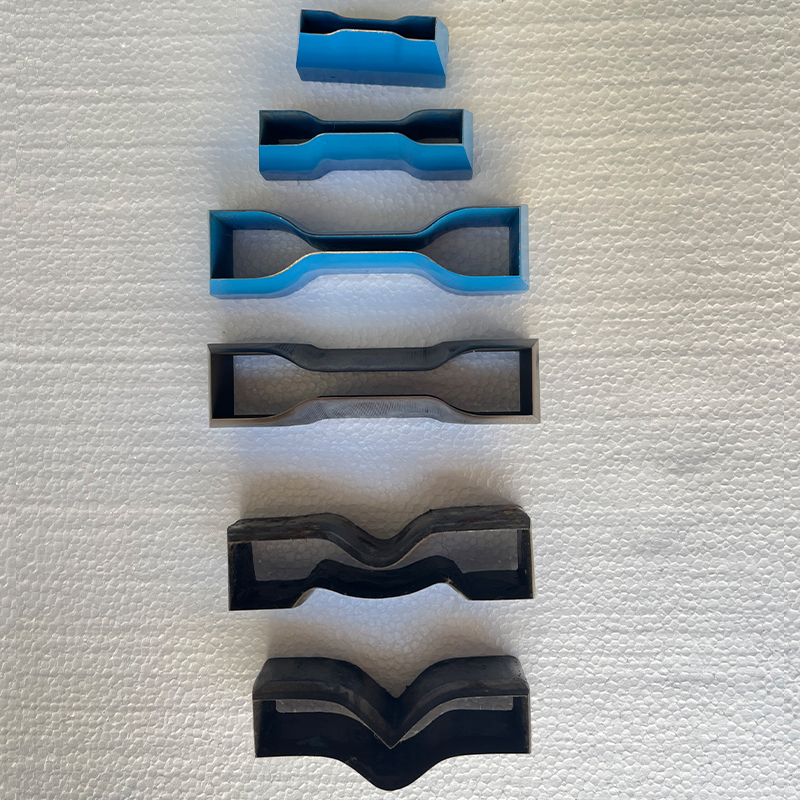

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy