Jan . 14, 2025 11:19

Back to list

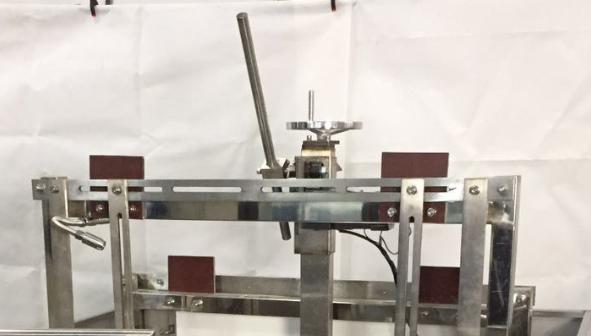

conductor resistance measurement machine

Unlocking the efficiency and efficacy of conductor resistance measurement machines can dramatically transform electrical testing and maintenance landscapes. For industries reliant on electrical components, ensuring optimal performance is paramount. As a seasoned engineer in electrical systems, my experience underscores the transformative impact these machines have across sectors.

Trust in these machines arises from their proven reliability in varied applications - from power generation to automotive industries. When deploying a conductor resistance measurement machine, relying on established brands with traceable performance histories enhances dependability. This commitment to quality assures that outcomes remain consistent, fostering trust among stakeholders. In terms of authority, institutions and organizations leveraging these technologies position themselves as leaders in electrical safety and quality assurance. Implementing such sophisticated diagnostic tools showcases a firm’s dedication to maintaining the highest standards, thereby attracting clientele who demand reliability. As with any advanced technology, understanding the operation and maintenance of resistance measurement machines is essential. Regular calibration and service by certified professionals ensure that the machines deliver peak performance. This maintenance fortifies their role as trustworthy partners in an engineer’s toolkit. In summary, the impact of conductor resistance measurement machines on operational efficiencies and cost reductions cannot be overstated. Their precise diagnostic capabilities not only enhance the expertise of professionals but also cultivate an environment of trustworthiness and authority. Companies integrating these tools demonstrate a commitment to excellence, ultimately fortifying their market position. As industries continue to expand and diversify, the importance of reliable and precise diagnostic tools like these will only grow, ushering in a new standard of electrical engineering excellence.

Trust in these machines arises from their proven reliability in varied applications - from power generation to automotive industries. When deploying a conductor resistance measurement machine, relying on established brands with traceable performance histories enhances dependability. This commitment to quality assures that outcomes remain consistent, fostering trust among stakeholders. In terms of authority, institutions and organizations leveraging these technologies position themselves as leaders in electrical safety and quality assurance. Implementing such sophisticated diagnostic tools showcases a firm’s dedication to maintaining the highest standards, thereby attracting clientele who demand reliability. As with any advanced technology, understanding the operation and maintenance of resistance measurement machines is essential. Regular calibration and service by certified professionals ensure that the machines deliver peak performance. This maintenance fortifies their role as trustworthy partners in an engineer’s toolkit. In summary, the impact of conductor resistance measurement machines on operational efficiencies and cost reductions cannot be overstated. Their precise diagnostic capabilities not only enhance the expertise of professionals but also cultivate an environment of trustworthiness and authority. Companies integrating these tools demonstrate a commitment to excellence, ultimately fortifying their market position. As industries continue to expand and diversify, the importance of reliable and precise diagnostic tools like these will only grow, ushering in a new standard of electrical engineering excellence.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy