cable burning tester factory

The Evolution of Cable Burning Tester Factories Ensuring Safety and Quality

The demand for reliable and high-performance cables in various industries has never been more critical. As technology advances, the importance of ensuring the integrity of these cables increases, leading to the emergence of specialized equipment aimed at testing their durability and safety—most notably, cable burning testers. These devices play a crucial role in manufacturing and quality assurance, and their production is centered in cable burning tester factories, which have evolved significantly over the years.

Understanding Cable Burning Testers

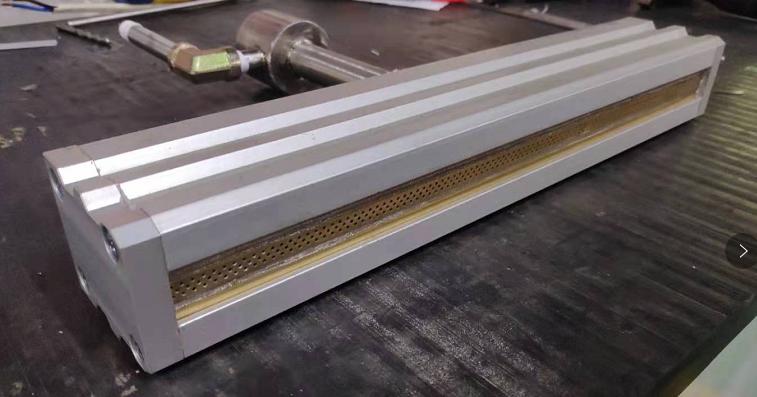

Cable burning testers are specialized machines designed to assess the fire resistance and behavior of electrical cables under extreme conditions. The primary function of these testers is to simulate real-life scenarios where cables may be subjected to heat and flames. By evaluating their performance, manufacturers can ensure compliance with safety standards and regulations, thereby protecting both consumers and end-users from potential hazards.

The testing process typically involves subjecting cables to a controlled flame while monitoring various parameters, such as temperature stability, ignition time, and the rate of combustion. The results provide critical data that informs manufacturers about the fire resistance of their products, enabling them to make necessary adjustments to materials or designs if needed.

The Role of Factories in Test Equipment Production

Cable burning tester factories are at the forefront of this safety initiative. These facilities are equipped with advanced technology and engineering expertise, allowing them to produce high-quality testing equipment. The manufacturing process involves the integration of sophisticated sensors, control systems, and safety features to ensure the testers can accurately replicate hazardous conditions without compromising safety.

Beyond the technological capabilities, these factories often prioritize rigorous quality control measures. Each unit produced undergoes extensive testing, often mimicking the scenarios for which they are designed. By doing so, they guarantee that the testers provide reliable, consistent results that manufacturers can trust.

Innovations in Testing Technology

As the industry evolves, so do the testing methods and machinery. Modern cable burning tester factories incorporate advanced materials and technologies. For instance, the integration of smart sensors and IoT capabilities has transformed traditional testing methods. These innovations enable real-time monitoring, data collection, and remote access, allowing engineers to analyze results efficiently and gain insights into performance trends.

cable burning tester factory

Furthermore, automation plays a significant role in enhancing the efficiency and accuracy of cable burning testers. Automated systems can consistently perform repetitive tasks, reducing human error and improving overall testing throughput. This increased efficiency not only speeds up the production of test equipment but also ensures that manufacturers can deliver high-quality cables to the market more rapidly.

Adapting to Global Standards

As regulatory bodies continue to update safety standards, cable burning tester factories must adapt their equipment accordingly. Compliance with international standards, such as IEC, UL, and ISO regulations, is crucial for manufacturers operating in a global marketplace. Ensuring that testing equipment meets these standards not only aids in regulatory approval but also builds consumer trust.

Cable burning tester manufacturers often work closely with regulatory agencies to ensure their products align with the latest guidelines. This collaborative approach fosters a safer environment for consumers while helping manufacturers keep pace with technological advancements.

The Future of Cable Burning Testing

Looking ahead, the future of cable burning tester factories is promising. With a growing emphasis on sustainability and eco-friendly materials, there will be an increasing need for testing equipment that can adapt to new advancements. Moreover, the push for smart grids and renewable energy solutions presents exciting opportunities for innovation within the industry.

As environmental concerns take center stage, factories will likely explore alternative testing methods that reduce waste and energy consumption. Incorporating sustainable practices in manufacturing cable burning testers not only creates a positive impact on the environment but also aligns with the values of an increasingly eco-conscious consumer base.

Conclusion

Cable burning tester factories play a vital role in the safety and reliability of electrical cables. By producing advanced testing equipment that adheres to stringent quality and safety standards, these facilities contribute significantly to protecting consumers and ensuring that manufacturers deliver superior products. As technology continues to evolve, so too will the capabilities of cable burning testers, paving the way for safer, more efficient electrical systems in the future.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy