cable smoke density test chamber supplier

Cable Smoke Density Test Chamber Suppliers Ensuring Safety in Electrical Installations

In today's world, where technology is ever-evolving, ensuring safety in electrical installations has become paramount. One critical aspect of this safety is the smoke density generated by cables during combustion. The cable smoke density test chamber plays a crucial role in analyzing the behavior of electrical cables when exposed to fire. This article explores the importance of cable smoke density test chambers, the suppliers that provide these essential devices, and the factors to consider when choosing a supplier.

Importance of Cable Smoke Density Testing

Smoke density refers to the amount of smoke produced when a cable burns. High levels of smoke generation can pose serious risks, including reduced visibility during evacuation procedures and increased inhalation hazards. Thus, assessing smoke density is vital for ensuring that cables meet safety regulations and standards. Test chambers designed for this purpose simulate fire conditions to evaluate the smoke production characteristics of various cables.

The results obtained from these tests help manufacturers develop cables that not only meet electrical requirements but also adhere to fire safety norms. Regulatory bodies across the globe mandate such testing to protect lives and property, making it an integral part of the cable manufacturing process.

Choosing the Right Supplier

When selecting a cable smoke density test chamber supplier, several factors come into play

1. Quality of Equipment The test chambers must be constructed using high-quality materials to withstand rigorous testing conditions. Ensure that the supplier you choose is known for providing durable and reliable equipment.

cable smoke density test chamber supplier

2. Compliance with Standards Confirm that the test chambers comply with national and international standards such as IEC, UL, or ASTM. This compliance assures that the results obtained from testing will be accepted by certifying bodies.

3. Technology and Features Look for suppliers that incorporate the latest technology and features in their test chambers. Modern testing equipment may offer enhanced data collection, reporting capabilities, and ease of use, which can significantly streamline the testing process.

4. Technical Support and Service A reputable supplier should offer excellent customer support, including installation assistance, calibration services, and maintenance options. This support is crucial for ensuring the longevity and proper functioning of the test equipment.

5. Cost-Effectiveness While it is essential to invest in high-quality equipment, pricing is also an important aspect. Compare prices across different suppliers while considering the features and benefits offered. This will help you achieve a balance between cost and quality.

6. Reputation and Experience Research the supplier's reputation in the industry. Look for customer reviews and testimonials. Suppliers with a long-standing presence in the market are likely to have a proven track record in delivering high-quality equipment.

Conclusion

Cable smoke density test chambers are indispensable tools for ensuring the safety of electrical installations. Choosing the right supplier is crucial to obtaining reliable testing equipment. By considering factors such as quality, compliance, technology, support, cost, and reputation, organizations can make informed decisions that contribute to enhanced safety standards in cable manufacturing. As we continue to advance in technology, prioritizing safety through rigorous testing ensures a more secure environment for everyone.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

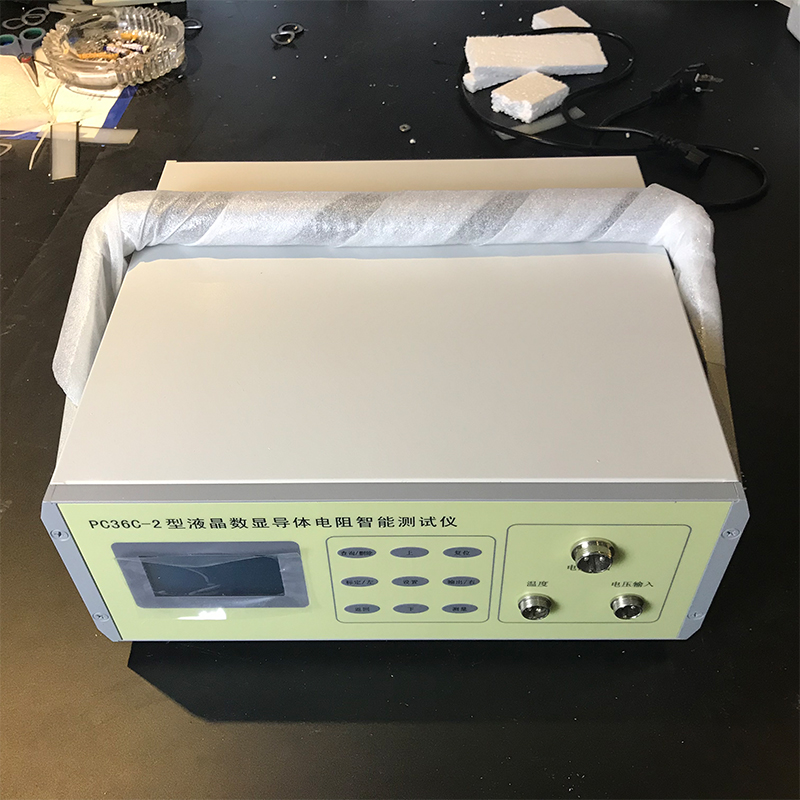

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy