Advanced Electronic Tensile Testing Equipment for Material Strength Evaluation and Analysis

Understanding Electronic Tensile Testing Machines Key Features and Applications

In the modern manufacturing and materials science fields, the demand for precise, reliable testing equipment is paramount. Amongst the various tools available, the electronic tensile testing machine stands out as a critical device for evaluating the mechanical properties of materials. This robust instrument measures how materials react to controlled tension until they yield, break, or fracture. It is extensively used across multiple industries, from aerospace to civil engineering, due to its accuracy and versatility.

What is an Electronic Tensile Testing Machine?

An electronic tensile testing machine is designed specifically to apply tensile stress to a material sample, evaluating its strength, ductility, elastic limit, and other mechanical properties. The machine operates via a system of grips that secure the sample, a loading mechanism that applies the tensile force, and electronic sensors that collect data throughout the testing process. Typically, these machines can be programmed to measure the force applied, the elongation of the sample, and other critical parameters, resulting in a detailed analysis of the material's behavior under stress.

Key Components and Functionality

The primary components of an electronic tensile testing machine include

1. Load Cell This sensor is pivotal in measuring the amount of force being applied to the sample. It converts the mechanical stress into an electrical signal, which is then processed by the machine's computer system.

2. Grips These are specialized fixtures designed to hold the sample securely. The grip design is critical; improper gripping can lead to premature failure that does not reflect the true properties of the material.

3. Crosshead This part moves up and down to apply tensile force. The speed at which the crosshead moves can be controlled, allowing for tests at various strain rates.

4. Data Acquisition System This electronic component gathers and processes data during the test, including stress, strain, and extensions, enabling the user to generate stress-strain curves and obtain detailed material properties.

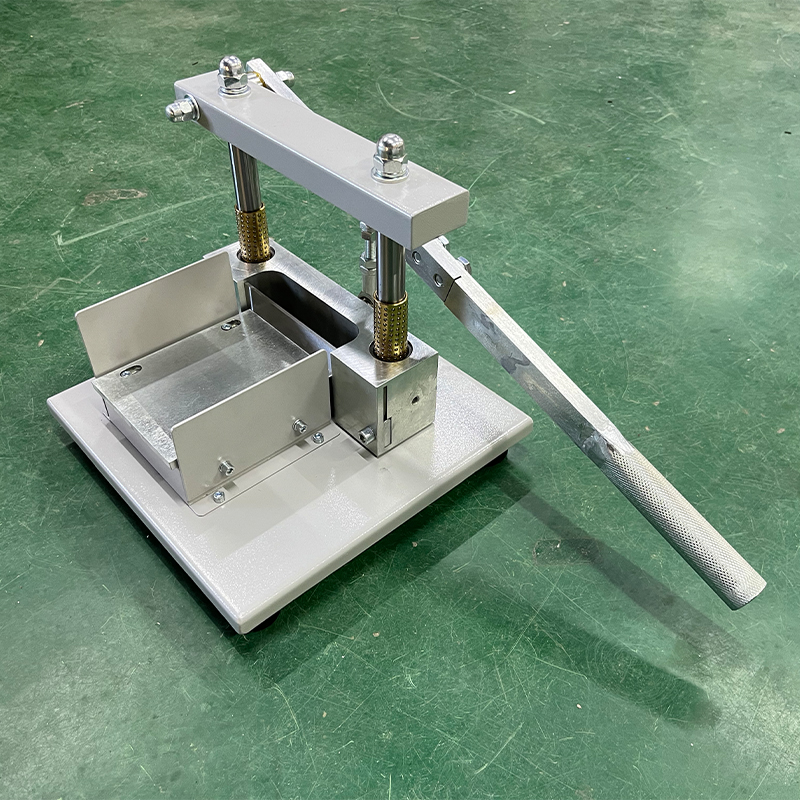

electronic tensile testing machine

5. Software Modern tensile testing machines are equipped with sophisticated software that facilitates the setup of tests, data collection, and analysis. Users can visualize results, generate reports, and perform statistical analyses, all critical for quality assurance and product development.

Applications of Electronic Tensile Testing Machines

The applications of electronic tensile testing machines are widespread and can be seen in many industries, including

- Materials Research and Development Engineers utilize tensile testing to develop new materials and enhance existing ones. Understanding how a material behaves under stress helps in innovating stronger, lighter, and more functional materials.

- Quality Control and Assurance In manufacturing, tensile testing is essential for ensuring that raw materials and finished products meet specified standards. This is particularly crucial in industries like aerospace and automotive where materials must adhere to strict safety regulations.

- Construction and Structural Engineering Tensile testing provides vital data concerning the strength and ductility of materials such as steel, concrete, and composites used in construction. Engineers rely on this data to design buildings and bridges that can withstand various forces.

- Textiles In the apparel industry, tensile testing evaluates the strength and elasticity of fabrics, ensuring they meet durability requirements.

- Plastic and Polymer Industries These materials often have varying properties based on their formulation and processing. Tensile testing helps manufacturers optimize formulations for strength and flexibility.

Conclusion

In summary, electronic tensile testing machines are invaluable tools within many industries, providing crucial insights into material properties that ensure safety, performance, and innovation. As technology advances, these machines continue to evolve, incorporating enhanced features that improve accuracy and efficiency in testing. Their role in the development and quality assurance of materials directly impacts product performance and longevity, making them essential in achieving excellence in manufacturing and engineering practices. Understanding the significance of these machines leads to better practices and improvements in material science and engineering, ultimately pushing the boundaries of what is possible in innovation and design.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy