measure machine for cables suppliers

Measuring Machines for Cable Suppliers Ensuring Quality and Precision

In the manufacturing industry, the need for precision and quality is paramount, especially for cable suppliers. Cables are essential components in various applications, from residential wiring to large industrial systems and telecommunications. To ensure that these cables meet stringent quality standards, accurate measurement is crucial. This is where measuring machines come into play, enhancing quality control processes and ensuring that suppliers deliver products that meet or exceed customer expectations.

Importance of Measurement in Cable Manufacturing

Cables must adhere to specific standards concerning dimensions, conductivity, insulation thickness, and overall durability. Any deviation from these specifications can lead to failures, safety hazards, or reduced lifespan of the products. Therefore, having high-quality measuring machines capable of assessing various attributes of cables is critical. These machines help in determining key parameters such as

1. Diameter Measurement The outer diameter of a cable must be measured accurately. Variations can affect how cables fit into conduits and connectors, potentially leading to installation issues.

2. Conductor Resistance This parameter measures how well the cable can conduct electricity, which is vital for performance. High-quality measuring machines can provide precise resistance readings to ensure compliance with electrical standards.

3. Insulation Thickness Insulation protects conductors and prevents electrical leakage. Accurate insulation thickness measurements ensure compliance with safety standards and enhance the cable's overall reliability.

4. Physical Characteristics Parameters such as tensile strength, elongation, and flexibility are crucial for determining the durability of cables. Measuring machines can conduct tests to ascertain these physical characteristics.

Types of Measuring Machines Used

There are various types of measuring machines utilized by cable suppliers, each designed to address specific measurement needs

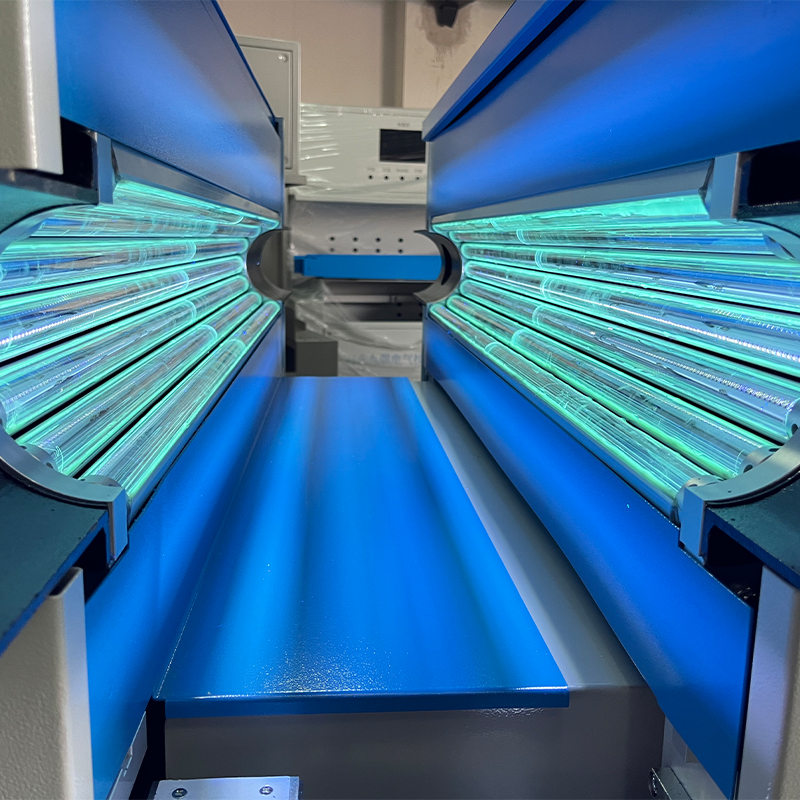

- Laser Measurement Systems These are known for their high precision

. Laser systems can measure diameters and lengths without contact, reducing the risk of damage to the cables during testing.measure machine for cables suppliers

- Resistance Testers These are used to measure electrical resistance in conductors. Ensuring that the resistance is within acceptable limits is fundamental to the efficiency of electrical cables.

- Thickness Gauges These machines assess insulation and sheathing thickness. Non-destructive testing methods ensure that measurements can be taken without harming the product.

- Tensile Test Machines These machines evaluate the strength of cables by subjecting them to tensile stress until failure. This testing reveals how much force cables can withstand in real-world applications.

Benefits of Advanced Measurement Technology

Investing in advanced measuring machines provides numerous benefits for cable suppliers

1. Enhanced Product Quality Regular and precise measurements lead to higher quality products. Suppliers can immediately identify and rectify anomalies in the manufacturing process.

2. Regulatory Compliance Many countries have specific regulations that cables must adhere to. Accurate measurement helps suppliers comply with these standards, avoiding legal issues and ensuring consumer safety.

3. Operational Efficiency Automated measuring machines can significantly reduce human error and increase the speed of the measurement process, enabling suppliers to maintain higher throughput rates.

4. Customer Satisfaction Delivering reliably measured and manufactured cables leads to improved customer satisfaction and trust, promoting loyalty and repeat business.

Conclusion

In summary, measuring machines are indispensable tools for cable suppliers, ensuring that products meet the rigorous standards necessary in today's market. By investing in advanced measurement technologies, suppliers can enhance product quality, comply with regulations, and ensure customer satisfaction. As the demand for reliable electrical infrastructure continues to grow, the importance of precise measurement in cable manufacturing will only increase. For suppliers looking to maintain a competitive edge, integrating modern measurement solutions is not just beneficial; it is essential.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy