mar . 07, 2025 02:31

Back to list

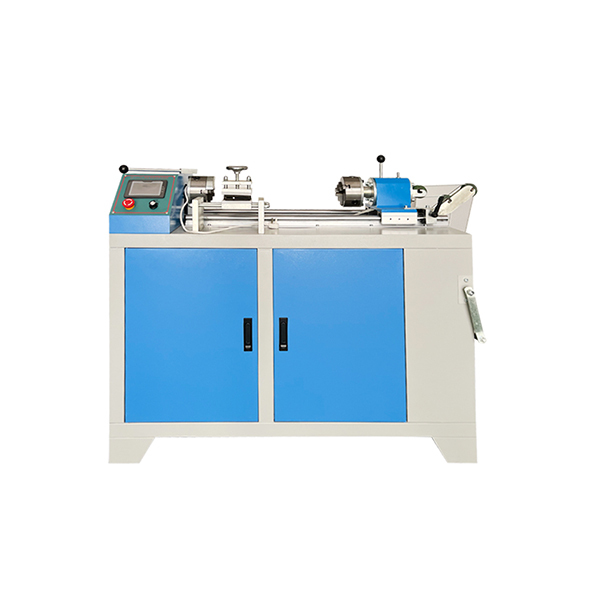

tensile yield tester factories

Navigating the intricate world of tensile yield tester factories presents a fascinating exploration for those keen on understanding how these pivotal devices shape industries. A tensile yield tester is not merely a tool; it is the cornerstone of quality, precision, and safety across various sectors, including automotive, aerospace, and construction. Understanding the nuances of these instruments demands an appreciation of the factories that produce them, guided by their expertise and commitment to excellence.

Trustworthiness is built over time through consistent product performance and customer relations. Factories known for their robust post-sale support and service networks instill confidence in their customers. By offering comprehensive training, timely maintenance, and responsive technical support, these factories build longstanding relationships with their clients. This customer-centric approach is often supported by a wealth of case studies and testimonials from industry leaders who attest to the dependability of the testers and the support provided. In the competitive landscape of tensile yield tester manufacturing, it is the blend of experience, expertise, authoritativeness, and trustworthiness that defines the most successful factories. These manufacturers not only deliver high-quality machines but also contribute significantly to advancing testing methodologies, thereby influencing standards and practices industry-wide. Their role is not limited to production; they are partners in progress, enabling businesses to innovate safely and efficiently. In conclusion, selecting the right tensile yield tester involves more than assessing the machine's capabilities; it requires an understanding of the factory's pedigree. This holistic consideration ensures that the tester is not just an investment in equipment but an investment in quality, reliability, and long-term success. Customers seeking the best in tensile testing technology would do well to scrutinize the underlying values and characteristics of the factories they choose. Such discernment promises to pay dividends in the form of enhanced product quality, safety, and operational excellence.

Trustworthiness is built over time through consistent product performance and customer relations. Factories known for their robust post-sale support and service networks instill confidence in their customers. By offering comprehensive training, timely maintenance, and responsive technical support, these factories build longstanding relationships with their clients. This customer-centric approach is often supported by a wealth of case studies and testimonials from industry leaders who attest to the dependability of the testers and the support provided. In the competitive landscape of tensile yield tester manufacturing, it is the blend of experience, expertise, authoritativeness, and trustworthiness that defines the most successful factories. These manufacturers not only deliver high-quality machines but also contribute significantly to advancing testing methodologies, thereby influencing standards and practices industry-wide. Their role is not limited to production; they are partners in progress, enabling businesses to innovate safely and efficiently. In conclusion, selecting the right tensile yield tester involves more than assessing the machine's capabilities; it requires an understanding of the factory's pedigree. This holistic consideration ensures that the tester is not just an investment in equipment but an investment in quality, reliability, and long-term success. Customers seeking the best in tensile testing technology would do well to scrutinize the underlying values and characteristics of the factories they choose. Such discernment promises to pay dividends in the form of enhanced product quality, safety, and operational excellence.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy