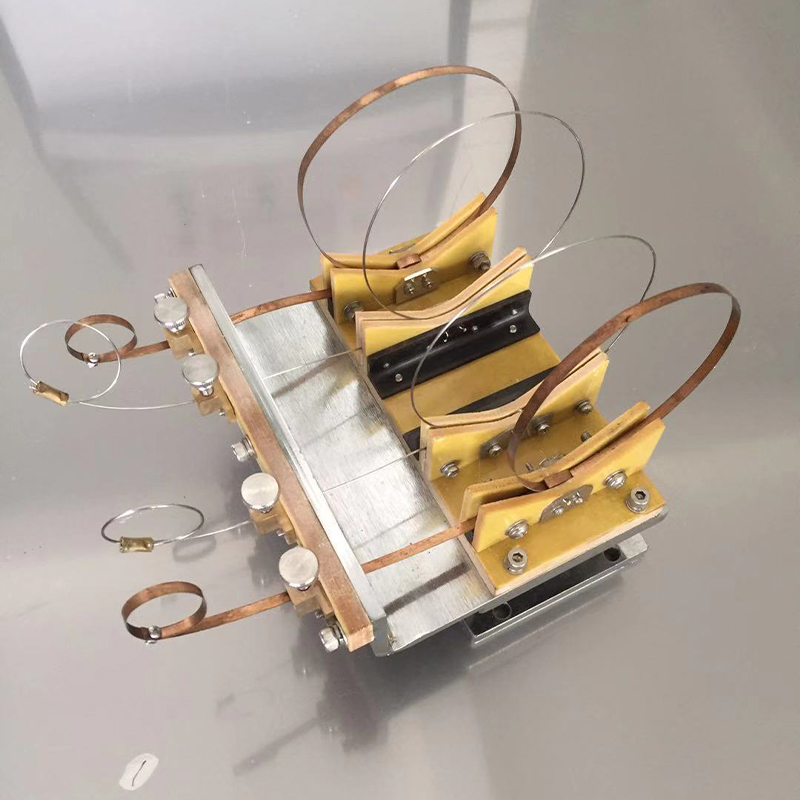

thermal stability tester

Understanding Thermal Stability Testers Importance and Applications

Thermal stability testers are vital instruments used in various industries to evaluate the thermal stability of materials, especially in the field of polymer science, aerospace, and automotive. These testers help determine how materials react to high temperatures over time, thus ensuring safety and reliability in their applications.

What is Thermal Stability?

Thermal stability refers to the ability of a material to maintain its physical and chemical properties when exposed to elevated temperatures. Materials can undergo thermal degradation, leading to a loss of strength, flexibility, and other essential characteristics. Therefore, assessing thermal stability is crucial for predicting a material's performance in real-world conditions, particularly where heat is a critical factor.

Why Use a Thermal Stability Tester?

1. Quality Control In manufacturing processes, maintaining quality standards is paramount. Thermal stability testers play a crucial role in quality assurance by evaluating the thermal properties of raw materials and finished products. Consistent testing can help manufacturers identify potential failures before they reach consumers, thereby reducing liability.

2. Material Development For researchers and engineers developing new materials, understanding thermal stability is essential. Thermal stability testers enable the assessment of various formulations, leading to innovative solutions with desirable properties that can withstand high-temperature applications.

3. Safety Assessment In industries like aerospace, automotive, and electronics, high temperatures can significantly impact the safety and functionality of components. Thermal stability testers help identify materials that can handle extreme conditions, ensuring that products meet safety regulations and industry standards.

4. Regulatory Compliance Many industries operate under strict regulations regarding the thermal characteristics of materials used in their products. Thermal stability testers assist companies in complying with these regulations by providing accurate data and documentation necessary for certification processes.

How Does a Thermal Stability Tester Work?

thermal stability tester

Thermal stability testing typically involves several methods, including Thermogravimetric Analysis (TGA), Differential Scanning Calorimetry (DSC), and dynamic mechanical analysis (DMA). Each method has its strengths and provides different insights into the thermal properties of a material.

- Thermogravimetric Analysis (TGA) TGA measures changes in a material’s weight as it is heated. It provides valuable data on thermal degradation temperatures and the composition of the material, helping identify the point at which a material begins to lose mass due to thermal effects.

- Differential Scanning Calorimetry (DSC) DSC is used to measure the heat flow associated with transitions in materials as a function of temperature. This technique reveals information about melting points, glass transitions, and thermal transitions, which are critical for understanding a material’s behavior under thermal stress.

- Dynamic Mechanical Analysis (DMA) DMA evaluates the mechanical properties of materials as they are subjected to temperature changes. It gives insight into how stiffness, viscosity, and elasticity of materials change when exposed to heat, allowing for a deeper understanding of material performance.

Applications of Thermal Stability Testers

- Polymer Industry In polymer development, it is essential to determine how various additives or formulations affect thermal stability. Thermal stability testers enable the screening of polymer blends and composites that meet specific thermal performance criteria.

- Aerospace and Automotive Components used in these industries must endure significant thermal stress. Thermal stability testing helps ensure that parts like tires, engine components, and structural elements maintain their integrity under high temperatures.

- Electronics With the rise of miniaturized electronic components generating heat, thermal stability testing becomes crucial for ensuring long-term reliability and performance.

Conclusion

Thermal stability testers are indispensable tools in the quest for safe, reliable, and efficient materials across various industries. By providing crucial insights into how materials behave at elevated temperatures, these testers support innovation while ensuring compliance with safety standards. As technology continues to evolve, the significance of thermal stability testing will only grow, paving the way for advancements in material science and engineering.

-

DQ-F Superfine Wire Conductor Resistance Fixture: High-Precision Testing

NewsAug.30,2025

-

ZC36 High Insulation Resistance: Reliable & Safe Performance

NewsAug.29,2025

-

CX-100 Manual Hydraulic Core Punching Machine - Efficient & Reliable

NewsAug.28,2025

-

Reliable Performance Testing with Advanced Aging Chamber Solutions

NewsAug.23,2025

-

Advancing Precision with Profile Projector Technology

NewsAug.23,2025

-

UV-LED Ultraviolet Crosslinking Technology: Innovation and Prospects

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy