Best Companies for Automatic Profile Projectors in the Industry Today

The Importance of Automatic Profile Projectors in Precision Measurement

In the realm of precision measurement and quality control, automatic profile projectors play a significant role in various manufacturing and engineering applications. Known for their ability to project the silhouette of an object onto a screen, these sophisticated instruments provide a reliable and efficient means to evaluate the geometry, dimensions, and contours of components with high accuracy. As industries continue to demand higher precision, the development and utilization of automatic profile projectors have seen substantial advancement.

The Importance of Automatic Profile Projectors in Precision Measurement

Companies specializing in the manufacturing of automatic profile projectors leverage advanced technologies such as digital imaging, automated measurement software, and enhanced optical systems to increase accuracy and efficiency. Noteworthy manufacturers in this sector include Mitutoyo, Zeiss, and Nikon, each offering robust features tailored to different applications. For instance, Mitutoyo’s projects are designed to enhance user experience with intuitive interfaces and automated functionalities that minimize the potential for human error.

automatic profile projector companies

One of the notable advantages of using automatic profile projectors is their ability to streamline the inspection process. Traditional measurement methods can be time-consuming and require a high level of skill, often resulting in inconsistencies. In contrast, automatic profile projectors can quickly analyze multiple features simultaneously, leading to faster turnaround times for quality assurance processes. Additionally, with the incorporation of digital technology, these projectors can record data, which helps in maintaining detailed compliance records for quality audits.

Furthermore, the integration of automatic profile projectors with computer-aided design (CAD) systems revolutionizes the way organizations approach design verification. With seamless connectivity to CAD software, operators can import design data directly into the inspection process, making it simpler to ensure that manufactured parts adhere to intricate specifications. This capability is particularly crucial in industries where precision is paramount, such as aerospace, where even minor deviations can have significant implications for safety.

In today's competitive market, the demand for precision and quality has led many companies to invest significantly in automatic profile projectors. This investment results in cost savings long-term by reducing scrap rates, minimizing rework, and improving productivity. Moreover, being able to validate parts with high precision contributes to customer satisfaction and trust, driving customer loyalty.

In conclusion, automatic profile projectors represent a vital advancement in precision measurement technology. Companies leveraging these devices are better equipped to ensure the quality and accuracy of their products, leading to enhanced operational efficiency and reduced costs. As industries evolve and the need for higher precision grows, the functionality and integration capabilities of automatic profile projectors will continue to play a crucial role, making them indispensable tools in the world of manufacturing and quality control. The future of precision measurement is not just about precision but also about the speed and reliability that automatic profile projectors bring to the table. Organizations that embrace these innovations will be well-positioned to thrive in an increasingly demanding market.

-

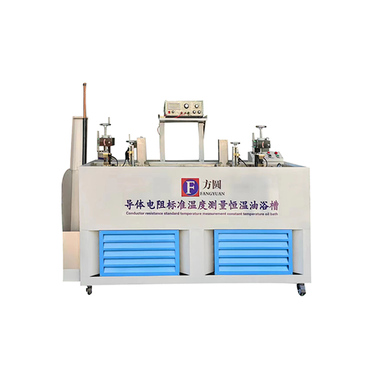

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy