cable cross-linked equipment manufacturer

The Rise of Cable Cross-Linked Equipment Manufacturers Innovations and Market Trends

In an era defined by rapid technological advancements, the demand for sophisticated and reliable equipment has surged. Among the various sectors, cable cross-linked equipment manufacturing has emerged as a significant player in meeting the needs of diverse industries, including telecommunications, energy, and construction. As industries increasingly rely on advanced networking and electrical solutions, the role of cable cross-linked equipment manufacturers becomes crucial. This article explores the innovations, manufacturing processes, and market trends shaping this dynamic field.

Understanding Cross-Linking

Before delving into the specifics of cable cross-linked equipment manufacturers, it is essential to understand what cross-linking entails. Cross-linking refers to the process of chemically bonding polymer chains to enhance their physical properties. In the context of cable manufacturing, cross-linked polyethylene (XLPE) is one of the most widely used materials due to its improved thermal resistance, electrical insulation, and durability. XLPE cables are known for their superior performance in high voltage applications, making them ideal for energy transmission and distribution networks.

The Role of Manufacturers

Cable cross-linked equipment manufacturers play a pivotal role in the production and supply of high-quality cables needed for various applications. These manufacturers employ cutting-edge technologies and advanced materials to ensure their products meet the rigorous standards set forth by regulatory bodies. They are responsible for delivering solutions that not only meet current demands but also anticipate future needs in an ever-evolving technological landscape.

Innovations in Cable Manufacturing

The cable cross-linked equipment manufacturing sector is witnessing numerous innovations aimed at enhancing cable performance and reliability. One major trend is the adoption of smart manufacturing technologies. The integration of the Internet of Things (IoT) and artificial intelligence (AI) into production lines allows for real-time monitoring and optimization of manufacturing processes. This not only improves efficiency but also minimizes the likelihood of defects, ensuring a higher quality end product.

cable cross-linked equipment manufacturer

Moreover, manufacturers are increasingly focusing on sustainability. The use of recyclable materials and environmentally friendly manufacturing processes are becoming commonplace. Companies are investing in research and development to create biodegradable and less environmentally harmful alternatives to traditional cable materials. This shift towards sustainable practices not only aligns with global trends but also appeals to consumers who are increasingly conscious of their environmental footprint.

Market Trends and Demand

The global demand for cable cross-linked equipment is on the rise, driven by several factors. The expansion of renewable energy projects, including solar and wind power, necessitates reliable and efficient cable solutions for energy transport. Additionally, the growing telecommunications infrastructure, propelled by the proliferation of 5G networks, adds to the demand for high-performance cables capable of handling increased data loads without compromising quality.

Furthermore, the construction industry is experiencing a surge in demand for durable and efficient electrical wiring systems. As urbanization accelerates and smart buildings become more prevalent, the need for innovative cable solutions that deliver safety and reliability is more critical than ever. Manufacturers are responding to these trends by developing specialized cables tailored to meet specific industry requirements, ensuring their products remain relevant and competitive.

Challenges and Opportunities

While the sector presents numerous opportunities, it is not without its challenges. Fluctuating raw material prices and supply chain disruptions can impact manufacturing costs and timelines. Additionally, as technology evolves rapidly, manufacturers must continually innovate and adapt to stay ahead of competitors. However, those who embrace change and invest in advanced technology and sustainable practices are likely to reap significant rewards.

Conclusion

In conclusion, cable cross-linked equipment manufacturers are at the forefront of a critical industry that supports various sectors through their innovative and reliable products. With ongoing advancements in technology and increasing demand across multiple industries, manufacturers who prioritize quality, sustainability, and adaptability will thrive in this competitive landscape. As the world continues to evolve, the importance of cable cross-linked solutions in maintaining connectivity and power integrity cannot be overstated. The future of cable manufacturing looks promising, driven by innovation and a commitment to meeting the challenges of tomorrow.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

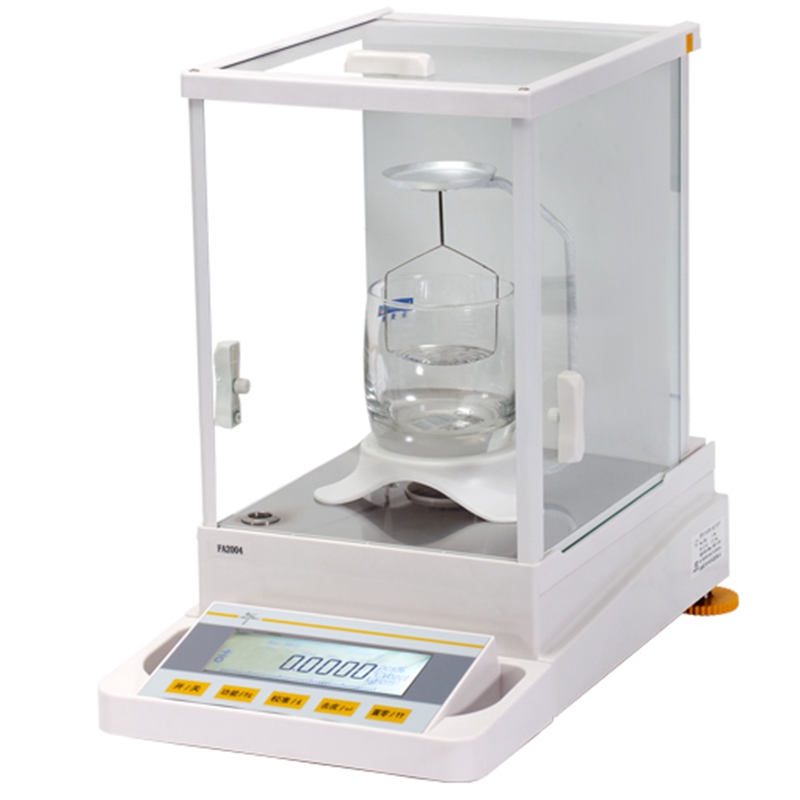

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy