Advanced Tensile Strength Testing Equipment for Precision Material Analysis and Quality Control

The Evolution of Computer-Controlled Tensile Strength Testers in Manufacturing

In the ever-evolving landscape of manufacturing, quality control and material testing have become paramount. One of the critical aspects of ensuring that materials meet industrial standards is through tensile strength testing. As technology advances, the methods used to conduct these tests have transitioned from manual processes to sophisticated computer-controlled tensile strength testers. This transformation has significantly enhanced accuracy, efficiency, and reliability in material testing.

Tensile strength testing is crucial for determining how materials react under tension. It involves applying a controlled load to a sample until it deforms or breaks while measuring the response. Traditionally, this process relied heavily on human operators, who would manually adjust settings, record data, and interpret results. This method, while effective, was often hampered by human error, inconsistencies, and time constraints.

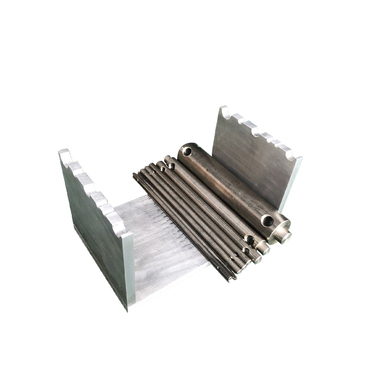

The introduction of computer-controlled tensile strength testers marks a significant leap forward in this industry. These advanced machines integrate cutting-edge technology to automate the testing process, providing a level of precision that was previously unattainable. At their core, these testers utilize highly sensitive sensors and sophisticated software algorithms to monitor and record various parameters such as load, elongation, and time. This data is then processed to generate comprehensive reports that detail the material's performance characteristics.

One of the standout features of modern computer-controlled tensile strength testers is their ability to conduct tests under a wide range of conditions. Manufacturers can customize testing protocols to meet specific material requirements, whether for metals, plastics, composites, or other materials. This flexibility ensures that the testing process can be tailored to meet industry standards and regulatory compliance, ultimately leading to better product quality and performance.

computer control tensile strength tester factory

Moreover, these state-of-the-art testers enhance efficiency in several ways. Automated systems reduce the time required to set up and conduct tests, allowing laboratories to process more samples in a shorter period. The consistency of results generated by these machines is also significantly higher than that of manual methods, as computer algorithms can standardize testing conditions and minimize variability. This high level of automation not only improves throughput but also ensures that companies can respond more quickly to changes in demand or product specifications.

Data management has also seen a revolution thanks to computer-controlled tensile strength testers. Advanced software platforms allow for seamless data collection and analysis, enabling manufacturers to track performance trends over time. This capability is especially valuable in industries such as aerospace, automotive, and construction, where material integrity is critical. With the ability to access historical data, manufacturers can make informed decisions regarding material selection and quality assurance processes.

In addition, these testers often come equipped with features like real-time monitoring and remote access capabilities. Operators can oversee testing processes from a distance, ensuring operational continuity even when physical presence is not feasible. This characteristic has proven particularly advantageous during times when remote working has become more prevalent due to global circumstances.

The computer-controlled tensile strength tester factory plays a vital role in producing these advanced machines. As demand for reliable testing equipment grows, manufacturers are investing in research and development to enhance functionality, improve user experience, and adopt more sustainable manufacturing practices. By continuously innovating, these factories are ensuring that their products remain at the forefront of technology, helping various industries maintain high standards of quality control.

In conclusion, the shift to computer-controlled tensile strength testers is revolutionizing the way material testing is conducted in the manufacturing sector. With enhanced accuracy, improved efficiency, and advanced data management capabilities, these machines are setting new benchmarks for quality assurance. As industries continue to advance and evolve, so too will the technology used to ensure the materials meet the stringent demands of a competitive market. The future promises even greater innovations, solidifying the importance of tensile strength testing in manufacturing processes.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy