Constant Temperature Testing for Conductor Resistance Evaluation by Exporters

Understanding Conductor Resistance and the Importance of Constant Temperature Testing for Exporters

In the realm of electrical engineering, ensuring the reliability and efficiency of conductors is paramount. Conductor resistance is a critical parameter that affects the performance of electrical systems. This article delves into the concept of conductor resistance, the significance of constant temperature tests, and the implications for exporters in the electrical equipment industry.

The Basics of Conductor Resistance

Conductor resistance is the measure of a conductor's opposition to the flow of electric current. It is influenced by several factors, including the material of the conductor, its cross-sectional area, length, and the temperature at which the measurement occurs. The resistance \( R \) in ohms (\( \Omega \)) can be calculated using the formula

\[ R = \rho \frac{L}{A} \]

Where - \( \rho \) is the resistivity of the material (in ohm-meters), - \( L \) is the length of the conductor (in meters), - \( A \) is the cross-sectional area (in square meters).

Understanding these factors is crucial for manufacturers and exporters who deal with electrical conductors. High-resistance conductors can lead to energy losses, overheating, and ultimately, system failures.

The Role of Temperature in Resistance Measurement

Temperature has a profound influence on conductor resistance. As temperature increases, so does the resistance of most conductive materials. This relationship is crucial for applications where conductors operate under varying thermal conditions. Thus, measuring resistance at a constant temperature allows for more accurate and consistent comparative assessments of conductor performance.

Constant Temperature Testing

Constant temperature testing involves measuring the resistance of conductors under controlled thermal environments. This standardization is essential for several reasons

1. Accuracy Non-constant temperature conditions can result in fluctuating resistance readings that mislead engineers and manufacturers about a conductor's true performance.

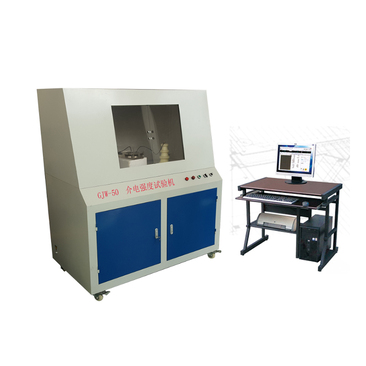

conductor resistance constant temperature test exporters

2. Reliability Exporters must ensure that their products adhere to international standards. Constant temperature testing forms the basis for many regulatory requirements, assuring that conductors will perform consistently across different environments.

3. Quality Assurance Regular resistance testing at a constant temperature helps identify manufacturing defects early in the production process. For exporters, this means fewer product recalls and improved customer satisfaction.

4. Comparative Analysis Conductors made from different materials or with various designs can be evaluated more easily when tests are performed under standardized conditions. This allows exporters to better position their products in the competitive market.

Implications for Exporters

For exporters in the electrical sector, understanding and implementing constant temperature resistance testing can significantly impact their business.

- Enhanced Product Quality By rigorously testing their products, exporters can guarantee high quality, reducing return rates and enhancing their brand's reputation.

- Compliance with Standards Many countries have stringent regulations regarding electrical safety and efficiency. Conducting constant temperature resistance tests helps ensure compliance, thus facilitating smoother entry into foreign markets.

- Consumer Trust Today’s consumers are increasingly conscious of product quality. Highlighting the rigorous testing processes, including constant temperature resistance testing, can build trust and drive sales.

- Competitive Advantage In a crowded marketplace, having a reputation for quality can set an exporter apart from competitors. By emphasizing advanced testing techniques, businesses can showcase their commitment to excellence.

Conclusion

Conductor resistance is a vital aspect of electrical engineering, directly affecting energy efficiency and safety. For exporters, the importance of constant temperature testing cannot be overstated. By ensuring that their conductors meet rigorous testing standards, exporters can enhance product quality, comply with international regulations, and build consumer trust. As the global demand for reliable electrical infrastructure continues to grow, the role of conductor resistance and its meticulous testing will remain indispensable in the pathway to success for exporters in this dynamic field.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy