Advanced Fiber Tensile Strength Testing Equipment for Custom Applications and Precision Measurements

Custom Fiber Tensile Strength Tester Ensuring Reliability in Material Testing

In today's fast-paced industrial environment, the demand for high-quality materials is more pressing than ever. From textiles to composite materials, industries need to ensure that their products withstand the rigors of use. One essential aspect of material quality is tensile strength, which indicates how much force a material can withstand while being stretched or pulled. This is where a custom fiber tensile strength tester plays a crucial role.

Understanding Tensile Strength Testing

Tensile strength testing is a standard procedure used across various industries to evaluate a material's durability and reliability. It involves applying a force to a specimen until it deforms or breaks. The results provide vital data on the material's performance characteristics, such as its yield strength, ultimate tensile strength, and elongation at break. This information is crucial for engineers and designers as they develop products that need to be safe, functional, and reliable.

The Need for Custom Solutions

While standard tensile strength testers can serve many applications, there are often unique requirements that standard devices cannot meet. Custom fiber tensile strength testers address these specific needs, allowing industries to test their materials under conditions that closely mimic real-world applications.

Custom tensile testers can be tailored to accommodate various fiber types, including synthetic fibers like nylon and polyester, as well as natural fibers such as cotton and wool. This customization ensures accurate testing results relevant to the specific materials being evaluated. Moreover, factors like specimen size, testing speed, and environmental conditions can be adjusted to provide insights that standard machines cannot offer.

Advantages of Custom Fiber Tensile Strength Testers

1. Precision and Accuracy Custom testers can be designed to meet precise specifications, ensuring that the testing process is accurate. This level of precision is particularly important in industries where even minor deviations can lead to significant problems, such as aerospace and medical device manufacturing.

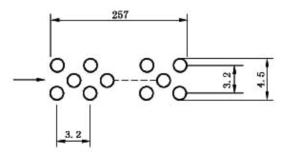

custom fiber tensile strength tester

2. Flexibility in Testing Conditions Custom testers can simulate various environmental factors, such as temperature and humidity, allowing for comprehensive testing. This flexibility means that manufacturers can assess how their materials will perform under different settings, thus better preparing for end-use conditions.

3. Enhanced Data Collection With customizable software and hardware, these testing machines can provide detailed reports and analytics. This data is invaluable for research and development teams focused on improving material formulations and processing techniques.

4. Compliance and Standards Different industries have unique regulations and testing standards, such as ISO and ASTM. Custom fiber tensile strength testers can be designed to comply with these standards, ensuring that manufacturers meet all necessary regulations for their products.

5. Improved Efficiency By tailoring the testing process to specific needs, companies can streamline operations. Custom testers can integrate with existing quality control systems, allowing for faster turnaround times and reducing manual oversight.

Implementing a Custom Fiber Tensile Strength Tester

The process of implementing a custom fiber tensile strength tester begins with a comprehensive analysis of the company’s needs. This includes identifying the types of materials frequently tested, the requirements for testing parameters, and any industry-specific certifications needed. Working closely with engineers and manufacturers who specialize in testing equipment ensures that the final product aligns with operational goals.

After installation, ongoing training for staff is critical to maximize the benefits of the new equipment. This training can cover everything from operating the machine and conducting tests to interpreting data and troubleshooting common issues.

Conclusion

In an era where material performance can significantly impact overall product quality, having the right testing equipment is non-negotiable. Custom fiber tensile strength testers offer the precision, flexibility, and efficiency that modern industries require to ensure their products meet the highest standards. By investing in tailored testing solutions, companies can not only enhance their material testing processes but also innovate and improve their product lines to stay competitive in a rapidly evolving market. As the demand for reliable products continues to grow, so too will the importance of custom testing solutions in ensuring material integrity and performance.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy