Exploring Leading Companies for Purchasing High-Quality Tensile Testing Equipment and Solutions

The Importance of Purchasing a Tensile Tester for Quality Control in Manufacturing

In the manufacturing landscape, quality control is paramount. One of the most critical aspects of quality control is ensuring that materials can withstand the stresses and strains of real-world applications. This is where purchasing a tensile tester becomes essential for companies that produce or utilize materials that undergo stretching or pulling.

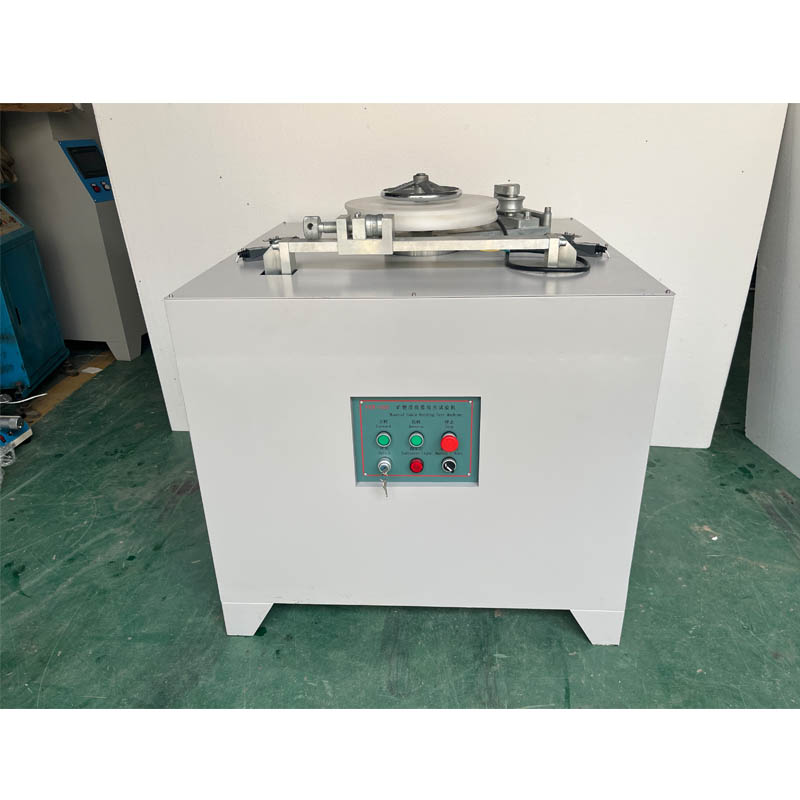

A tensile tester, also known as a universal testing machine (UTM), is an essential piece of equipment used to measure the mechanical properties of materials under tension. It provides valuable insights into the material's tensile strength, elongation, and other important characteristics. Given the diverse applications in industries such as construction, automotive, aerospace, and textiles, investing in a high-quality tensile tester can significantly enhance a company's quality assurance capabilities.

The Importance of Purchasing a Tensile Tester for Quality Control in Manufacturing

Another key aspect to consider is the testing speed and accuracy of the tensile tester. High-quality machines provide precise readings and can generate data at varying speeds, which is crucial for determining a material's behavior under different conditions. These accurate measurements are not only vital for internal quality control but can also be indispensable when presenting findings to clients or regulatory bodies.

purchasing tensile tester company

Moreover, durability and reliability are critical factors in selecting a tensile tester. A company should assess the reputation of the manufacturer or supplier, considering warranty offerings, customer service support, and the availability of replacement parts. A dependable tensile tester can withstand years of use, providing consistent performance and protecting the company’s investment.

In addition to these practical considerations, companies should also evaluate the ease of use and software compatibility of the tensile tester. Modern machines often come with advanced software that can analyze data, generate reports, and facilitate easy record-keeping. A user-friendly interface can significantly reduce training time for new operators, allowing them to focus on quality control without getting bogged down by complicated machinery.

Purchasing a tensile tester not only aids in meeting quality standards but can also contribute to product innovation. By understanding the mechanical properties of materials, companies can explore new manufacturing processes, develop new products, and ultimately enhance their competitive edge in the market. The data gleaned from these tests can guide research and development, ensuring that new materials are viable and safe for their intended applications.

In conclusion, investing in a tensile tester is a strategic decision for companies committed to maintaining high-quality standards in their products. By understanding the mechanical properties of the materials used in production, manufacturers can improve safety, compliance, and customer satisfaction. As industries evolve and new materials emerge, having access to precise testing equipment like a tensile tester is more critical than ever. This investment not only pays off in enhanced quality control but also in the long-term growth and success of the business. Thus, it is imperative for manufacturers to carefully consider their options when choosing a tensile tester to ensure they are equipped for the challenges of today and tomorrow.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy