Gen . 13, 2025 13:40

Back to list

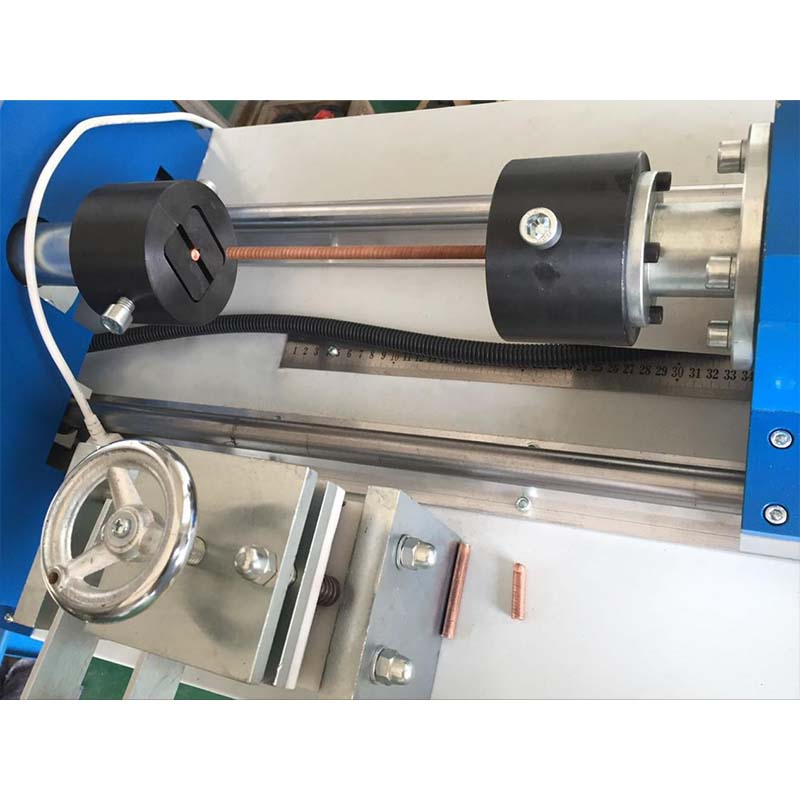

LED Ultraviolet Irradiation Polyolefin Crosslinking Equipment

When it comes to ensuring the utmost safety and compliance in cable manufacturing and installation, the significance of cable burning test equipment cannot be overstated. In various industries where cables play a critical role, such as telecommunications, energy, building construction, and transportation, understanding the fire resistance and smoke emission characteristics of cables is crucial. This is where specialized cable burning test equipment becomes indispensable, offering accurate evaluation and assurance.

Authoritativeness in cable testing arises from utilizing equipment from renowned manufacturers who have set industry benchmarks. Trustworthy manufacturers invest in research and development to introduce innovations that make testing more efficient and accurate. Partnering with such experts not only enhances the reliability of test results but also ensures compliance with global standards, thereby reinforcing the manufacturer's reputation. From a trustworthiness perspective, the information and outcomes provided by cable burning test equipment are vital. They form the backbone of safety assessments and certifications that regulators rely on to permit the usage of cables in various applications. Independent laboratories and certification bodies depend heavily on this equipment to furnish accurate data that influence their decisions about product reliability and safety. Therefore, selecting the right cable burning test equipment is crucial for manufacturers intent on maintaining compliance and achieving excellence in product safety. As the industry evolves and new materials and technologies emerge, staying informed about advancements in test equipment capabilities will remain paramount for professionals. By prioritizing quality, precision, and compliance, industries can ensure that their cable products meet the ever-growing safety expectations of global markets.

Authoritativeness in cable testing arises from utilizing equipment from renowned manufacturers who have set industry benchmarks. Trustworthy manufacturers invest in research and development to introduce innovations that make testing more efficient and accurate. Partnering with such experts not only enhances the reliability of test results but also ensures compliance with global standards, thereby reinforcing the manufacturer's reputation. From a trustworthiness perspective, the information and outcomes provided by cable burning test equipment are vital. They form the backbone of safety assessments and certifications that regulators rely on to permit the usage of cables in various applications. Independent laboratories and certification bodies depend heavily on this equipment to furnish accurate data that influence their decisions about product reliability and safety. Therefore, selecting the right cable burning test equipment is crucial for manufacturers intent on maintaining compliance and achieving excellence in product safety. As the industry evolves and new materials and technologies emerge, staying informed about advancements in test equipment capabilities will remain paramount for professionals. By prioritizing quality, precision, and compliance, industries can ensure that their cable products meet the ever-growing safety expectations of global markets.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy