ultraviolet irradiation polyolefin cross-linked equipment

Ultraviolet Irradiation Polyolefin Cross-Linked Equipment An Overview

Ultraviolet (UV) irradiation technology has significantly advanced material science, particularly in enhancing the performance of polyolefin plastics through cross-linking processes. Cross-linking of polyolefins via UV irradiation is a pivotal technique in producing materials that exhibit improved mechanical, thermal, and chemical properties. This article explores the principles of ultraviolet irradiation, the cross-linking process, the equipment involved, and application areas of UV-cross-linked polyolefins.

Understanding UV Irradiation

Ultraviolet irradiation refers to the process of exposing materials to UV light, which is a form of electromagnetic radiation. This exposure can initiate chemical reactions in the material, particularly in polymer chains. For polyolefins, which include widely used plastics like polyethylene (PE) and polypropylene (PP), UV irradiation can facilitate cross-linking. This process involves the formation of covalent bonds between polymer chains, resulting in a three-dimensional network structure.

The primary advantage of cross-linking is that it imparts improved mechanical strength, elasticity, and resistance to solvents and high temperatures. Cross-linked polyolefins can outperform their linear counterparts in various applications, making UV irradiation a valuable technique in the industry.

The Cross-Linking Process

The cross-linking process of polyolefins using UV irradiation involves several key steps

1. Material Preparation The polyolefin resin is typically mixed with suitable photoinitiators, which are compounds that generate free radicals upon exposure to UV light. These free radicals are crucial for initiating the cross-linking reaction.

2. UV Exposure The prepared material is subjected to UV irradiation under controlled conditions. The intensity and duration of exposure are critical parameters that influence the extent of cross-linking.

3. Curing Post-irradiation, the materials may undergo a curing phase where the chemical reactions complete, resulting in a cross-linked structure. This curing ensures that the desired properties are achieved.

4. Cooling and Post-Processing After curing, the materials are cooled, and any necessary post-processing steps (such as cutting, shaping, or finishing) are performed to finalize the product.

Equipment Involved in UV Cross-Linking

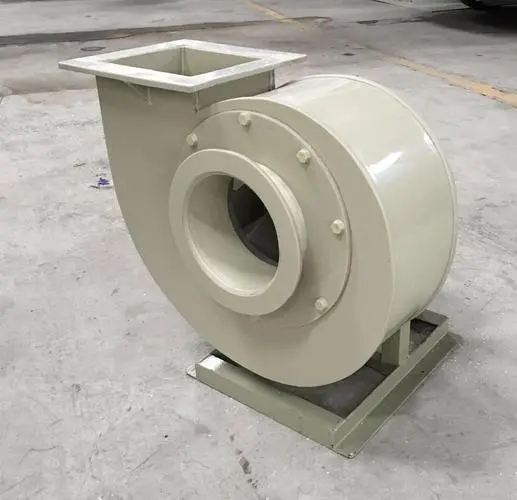

The equipment used for UV irradiation and cross-linking varies in complexity and scale

. Some common types of UV cross-linking equipment includeultraviolet irradiation polyolefin cross-linked equipment

- UV Lamps These are the primary source of UV light. They can be mercury vapor lamps, low-pressure mercury lamps, or LEDs, each varying in wavelength and intensity.

- Conveyor Systems In industrial settings, conveyor systems are often employed to pass materials through a UV irradiation zone, ensuring even exposure and efficiency.

- Reflectors and Filters Reflectors may be used to enhance UV light distribution, while filters can ensure the correct wavelengths are used to optimize the cross-linking process.

- Cooling Systems To prevent overheating during UV irradiation, cooling systems are often integrated into the equipment.

- Control Panels Modern UV cross-linking systems are equipped with sophisticated control panels that allow operators to monitor and adjust parameters such as time, intensity, and temperature.”

Applications of UV-Cross-Linked Polyolefins

The applications of UV-cross-linked polyolefins are vast, spanning various industries

- Automotive UV-cross-linked polyolefins are used in automotive parts that require enhanced durability and resistance to heat and chemicals, such as fuel lines and wiring insulation.

- Construction In construction, these materials are employed in roofing membranes, insulation, and geotextiles due to their improved waterproofing and weather resistance properties.

- Medical Devices The medical industry benefits from UV-cross-linked materials in the manufacturing of devices and equipment that demand stringent sterilization and hygiene standards.

- Electrical and Electronic Components UV-cross-linked polyolefins are also relevant in the electrical sector where they are utilized in insulation and protective coatings for wires and cables.

Conclusion

Ultraviolet irradiation for polyolefin cross-linking is an innovative technology that has transformed the material properties of plastics, leading to enhanced performance in numerous applications. The equipment involved in this process, from UV lamps to control systems, is critical for achieving precise and effective cross-linking. As industries continue to seek materials with superior characteristics, the role of UV irradiation in producing high-quality polyolefins will likely expand, further driving advancements in material science and engineering.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy