automatic measuring imager manufacturer

The Evolution and Impact of Automatic Measuring Imager Manufacturers

In the modern landscape of technology, the role of automatic measuring imager manufacturers has become increasingly significant. These manufacturers specialize in producing advanced imaging equipment that can measure various parameters automatically, leading to more accurate data collection, enhanced productivity, and reduced human error. The evolution of this technology is a reflection of the growing demand for precision in various industries such as healthcare, manufacturing, construction, and automotive.

Understanding Automatic Measuring Imagers

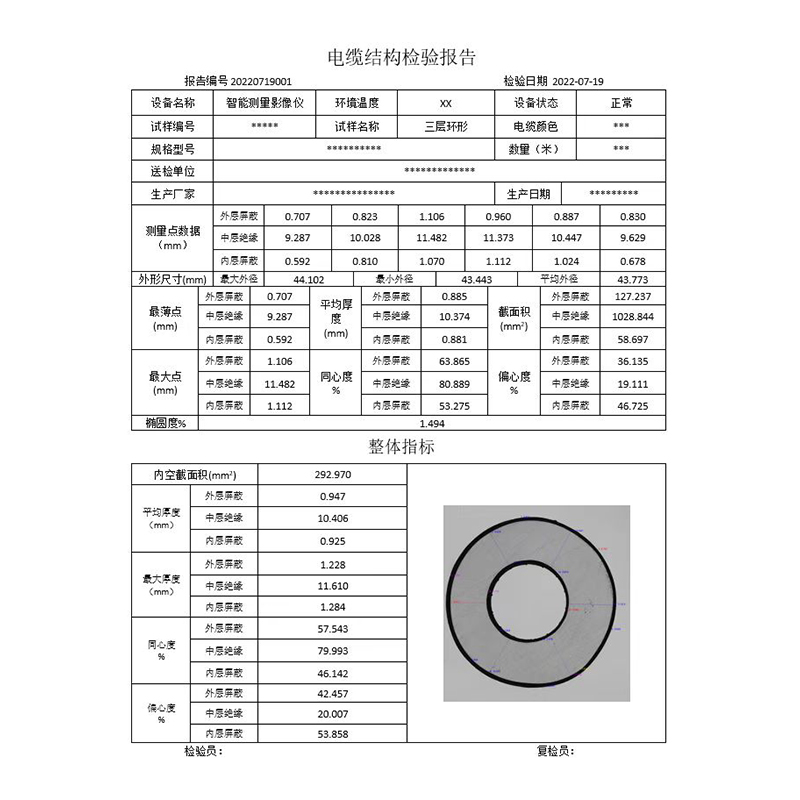

Automatic measuring imagers are sophisticated devices that utilize various technologies, such as laser scanning, infrared, and optical systems, to capture images and measurements of physical objects. Unlike traditional measuring tools that require manual operation, these devices can function autonomously, capturing data at incredibly high speeds and with exceptional accuracy.

The fundamental principle behind automatic measuring imagers lies in their ability to integrate imaging technology with measurement algorithms. For instance, a laser scanner can generate a three-dimensional model of an object by measuring distances at numerous points, while optical systems can analyze surface conditions without contact. This capability not only enhances the measurement process but also opens up new avenues for analysis and quality control.

The Industrial Revolution

The rise of automatic measuring imager manufacturers can be traced back to the industrial revolution. As industries evolved, the need for more precise measurements became apparent. Traditional measuring instruments often lacked the capability to provide real-time data, leading to inefficiencies and increased operational costs. The introduction of automatic measuring imagers marked a turning point, allowing manufacturers to streamline processes and reduce wastage.

Today, automatic measuring imagers are an integral part of the manufacturing ecosystem. They play a crucial role in quality assurance, ensuring that products meet stringent specifications before they leave the production line. By incorporating these technologies, manufacturers can not only guarantee the quality of their products but also significantly reduce the time and manpower required for inspections.

automatic measuring imager manufacturer

Benefits Across Various Sectors

The benefits of automatic measuring imagers are evident across multiple sectors. In healthcare, for instance, they are used for non-invasive imaging techniques that allow for precise diagnostics. These devices can measure everything from body composition to blood flow, enhancing patient care by providing physicians with reliable data to support clinical decisions.

In construction, automatic measuring imagers are revolutionizing site surveying and monitoring. Drones equipped with imaging technology can quickly assess land, providing real-time data that is essential for project planning and management. This not only saves time but also helps in maintaining safety standards by identifying potential hazards before they become issues.

The automotive industry also reaps significant advantages from these technologies. Automatic measuring imagers are deployed in the design and manufacturing processes to ensure automotive components fit together flawlessly. This precision in the manufacturing stage not only accelerates production but also results in higher-quality vehicles that meet safety standards.

The Future of Automatic Measuring Imager Manufacturers

As technology continues to advance, the future of automatic measuring imager manufacturers looks promising. Innovations in artificial intelligence, machine learning, and sensor technology are expected to enhance the capabilities of these devices. For example, AI algorithms can analyze large datasets generated by automatic measuring imagers, enabling predictive maintenance and improving operational efficiency.

Moreover, as industries move towards automation and Industry 4.0 practices, the integration of automatic measuring imagers with other smart technologies will become more prevalent. This will facilitate a holistic approach to data management, allowing for real-time monitoring and decision-making processes that were previously unattainable.

In conclusion, automatic measuring imager manufacturers are playing a critical role in the progression of technology across various industries. Their ability to provide precise, real-time measurements is transforming processes, enhancing quality, and propelling businesses toward greater efficiency. As these technologies continue to evolve, they will undoubtedly open new frontiers in data collection and analysis, setting the stage for a smarter and more productive future. The journey of automatic measuring imagers is just beginning, and their impact will likely resonate across generations to come.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy