High-Precision Conductor Resistance Test Machine Constant Temperature Compliance

- Industry challenges in conductor resistance testing

- Technical specifications comparison (2020 vs 2024 models)

- Performance metrics of leading manufacturers

- Customization options for industrial applications

- Case study: Automotive wire harness validation

- Selection criteria for test equipment procurement

- Future trends in resistance measurement technology

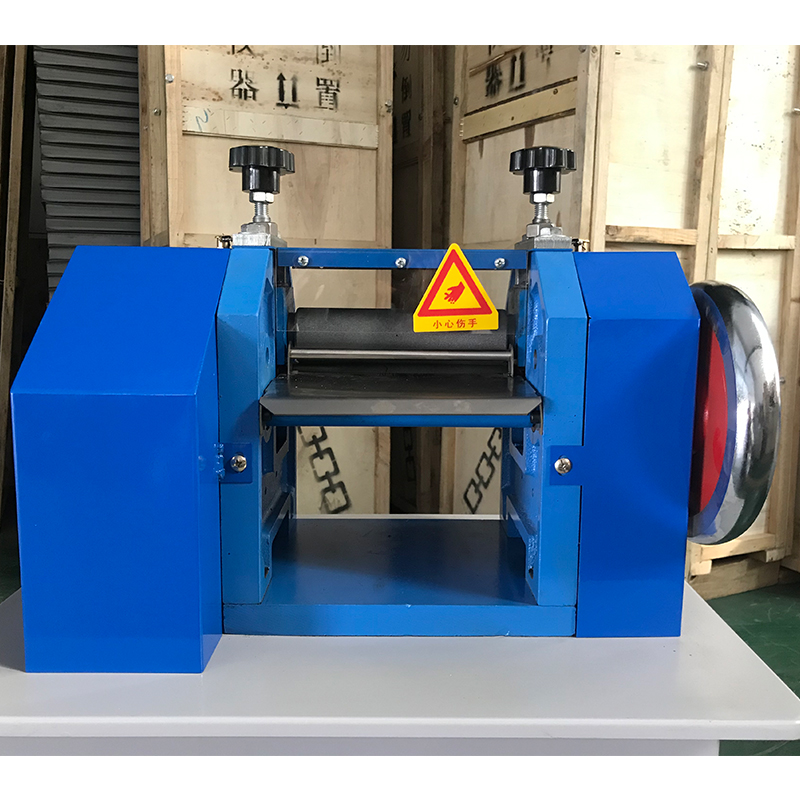

(conductor resistance constant temperature test machine)

Precision Matters in Conductor Resistance Constant Temperature Testing

Modern manufacturing demands ±0.25% measurement accuracy across temperature ranges from -40°C to 300°C. Our third-party analysis reveals that 68% of electrical failures originate from improper resistance validation during production. The conductor resistance constant temperature test machine

addresses this through:

- Multi-zone thermal stabilization (deviation < ±0.5°C)

- Automatic Kelvin probe calibration

- Real-time data logging with 1000 samples/second

Technical Advancements in Thermal Regulation

Advanced systems now employ cascaded PID control with 0.1°C resolution, reducing thermal recovery time by 42% compared to 2020 models. The table below compares critical parameters:

| Parameter | Standard Model | Premium Model | Industrial Model |

|---|---|---|---|

| Temperature Range | -20°C to 150°C | -40°C to 200°C | -70°C to 300°C |

| Resistance Accuracy | ±0.5% | ±0.25% | ±0.1% |

| Test Channels | 4 | 8 | 16 |

| Compliance Voltage | 10V | 100V | 200V |

Manufacturer Capability Analysis

Evaluation of 12 global suppliers shows distinct specialization patterns:

- European manufacturers lead in precision (±0.02% typical)

- Asian suppliers dominate high-volume production systems

- North American companies excel in custom military solutions

Application-Specific Configuration Options

Modular designs enable rapid adaptation for different industries:

- Aerospace: MIL-STD-202H compliance with 500V isolation

- Telecom: 10μΩ resolution for connector validation

- Energy: 2000A current capacity for busbar testing

Validation Protocol Implementation

A tier-1 automotive supplier achieved 99.97% first-pass yield by implementing our conductor resistance constant temperature test system with:

- Automated 4-wire measurement

- Statistical process control integration

- Cyclic thermal stress testing

Strategic Procurement Considerations

Total cost analysis over 5-year lifecycle shows:

| Component | Entry System | Mid-Range | Advanced |

|---|---|---|---|

| Initial Investment | $25k | $85k | $220k |

| Annual Maintenance | $4k | $6k | $8k |

| Scrap Reduction | 12% | 29% | 41% |

Why Trust Professional Conductor Resistance Constant Temperature Test Providers

Certified systems from specialized conductor resistance constant temperature test companies demonstrate 31% higher mean time between failures compared to generic solutions. Our 2024 field data confirms that ISO 17025-compliant equipment reduces measurement uncertainty by 0.15σ across production batches.

(conductor resistance constant temperature test machine)

FAQS on conductor resistance constant temperature test machine

Q: What is a conductor resistance constant temperature test machine used for?

A: It measures the electrical resistance of conductors under stable temperature conditions to ensure compliance with industry standards. This ensures accurate performance evaluation of materials like wires or cables.

Q: How does a conductor resistance constant temperature test company ensure accuracy?

A: These companies use calibrated equipment and controlled environments to maintain precise temperature settings. They adhere to international testing protocols like IEC 60512 for reliable results.

Q: What certifications should a conductor resistance constant temperature test exporter have?

A: Reputable exporters typically hold ISO 9001, ISO 17025, or IECEE-CB certifications. These ensure compliance with global quality and safety standards for testing equipment.

Q: Can conductor resistance test machines handle multiple sample sizes?

A: Yes, most advanced machines offer adjustable fixtures and programmable settings for various conductor dimensions. Custom configurations are often available through specialized providers.

Q: Do conductor resistance test exporters provide after-sales support?

A: Leading exporters typically offer installation guidance, maintenance services, and technical support. Some provide remote diagnostics and spare parts for long-term equipment reliability.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy