Feb . 14, 2025 08:05

Back to list

china cable winding test machine

China cable winding test machines are revolutionizing the electrical and telecommunications industries globally. Designed for precision, these machines streamline the cable manufacturing process, ensuring consistent quality and reliability. Delving into the intricacies of these advanced systems provides invaluable insights for businesses looking to optimize their production lines and enhance product performance.

The trustworthiness of China cable winding test machines is further validated by adherence to global safety and quality standards. Many manufacturers have obtained certifications such as ISO 9001, which attest to their commitment to quality management systems. Such certifications play a significant role in building confidence among users and stakeholders. A unique advantage of these machines is their versatility, enabling them to accommodate a range of cable types—from fiber optics to heavy-duty power cables. This adaptability is essential for manufacturers who aim to maintain flexibility in an ever-evolving market, providing them with the ability to quickly adapt to new specifications or industry standards. The real-world impact of these machines extends to end-product performance. Quality assurance achieved through advanced testing and winding technologies directly translates to enhanced reliability of the final product. This not only satisfies consumer expectations but also reduces the likelihood of costly recalls and reputational damage. Expanding beyond their manufacturing prowess, China cable winding test machines are instrumental in supporting sustainable practices. Their efficient use of materials and energy aligns with global initiatives towards reducing carbon footprints and promoting eco-friendly production processes. Businesses adopting these machines can significantly contribute to environmental sustainability while benefiting economically through reduced operational costs. In conclusion, China cable winding test machines represent the pinnacle of innovation in cable production technology. Their sophisticated design, backed by robust support systems and adherence to quality standards, ensures they remain a cornerstone of effective manufacturing strategies. For businesses seeking to navigate the complexities of modern production environments, investing in these machines offers a pathway to achieving excellence, reliability, and sustainability in their operations.

The trustworthiness of China cable winding test machines is further validated by adherence to global safety and quality standards. Many manufacturers have obtained certifications such as ISO 9001, which attest to their commitment to quality management systems. Such certifications play a significant role in building confidence among users and stakeholders. A unique advantage of these machines is their versatility, enabling them to accommodate a range of cable types—from fiber optics to heavy-duty power cables. This adaptability is essential for manufacturers who aim to maintain flexibility in an ever-evolving market, providing them with the ability to quickly adapt to new specifications or industry standards. The real-world impact of these machines extends to end-product performance. Quality assurance achieved through advanced testing and winding technologies directly translates to enhanced reliability of the final product. This not only satisfies consumer expectations but also reduces the likelihood of costly recalls and reputational damage. Expanding beyond their manufacturing prowess, China cable winding test machines are instrumental in supporting sustainable practices. Their efficient use of materials and energy aligns with global initiatives towards reducing carbon footprints and promoting eco-friendly production processes. Businesses adopting these machines can significantly contribute to environmental sustainability while benefiting economically through reduced operational costs. In conclusion, China cable winding test machines represent the pinnacle of innovation in cable production technology. Their sophisticated design, backed by robust support systems and adherence to quality standards, ensures they remain a cornerstone of effective manufacturing strategies. For businesses seeking to navigate the complexities of modern production environments, investing in these machines offers a pathway to achieving excellence, reliability, and sustainability in their operations.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

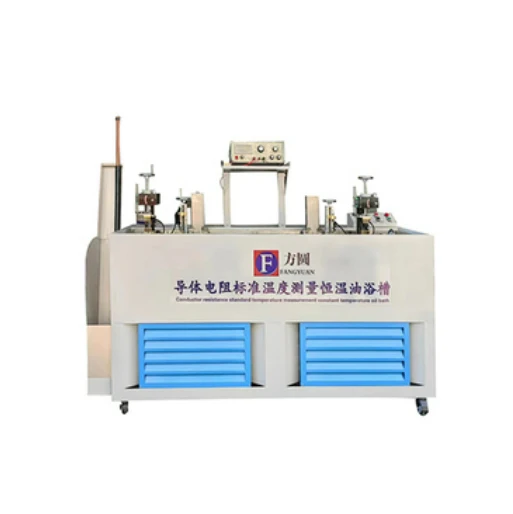

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy