Tensile Testing Equipment for Elastomers Following ASTM D412 Standards in China

Understanding the China Tensile Tester in Compliance with ASTM D412

In the realm of material testing, the tensile tester plays a crucial role, particularly for rubber and elastomer products. One of the key standards in this category is ASTM D412, which outlines the methods for testing the tensile properties of rubber. As industries evolve and demand for quality increases, China has become a significant player in manufacturing tensile testers that comply with ASTM standards, including D412.

The Importance of ASTM D412

ASTM D412 is a widely recognized standard that provides guidelines for measuring the tensile strength, elongation, and other mechanical properties of rubber materials. These properties are essential in determining how a rubber product will perform in various applications, be it automotive, aerospace, or industrial uses. The data generated from the ASTM D412 tests helps manufacturers ensure that their products meet quality and safety regulations, aiding in the consistency and reliability that end-users expect.

The standard emphasizes the need for accurate and repeatable testing procedures. It outlines stipulations about the specimen preparation, testing equipment, and the testing environment. Adhering to these guidelines helps in producing valid and comparable results across different laboratories and manufacturers, making it a critical aspect of material quality assurance.

China’s Role in Tensile Testing Equipment

In recent years, China has emerged as a leading manufacturer of tensile testing machines, including those compliant with ASTM D412. The country’s robust industrial infrastructure and advancements in technology have allowed Chinese manufacturers to produce high-quality testing equipment at competitive prices. As a result, many companies around the world are turning to Chinese suppliers for their tensile testing needs.

Chinese tensile testers designed for ASTM D412 compliance offer several advantages. They are typically equipped with advanced features such as electronic load measurement, computer-controlled testing, and data acquisition systems. These features ensure precise measurements and the ability to record data in real time, streamlining the testing process and enhancing productivity.

Features of China Tensile Testers

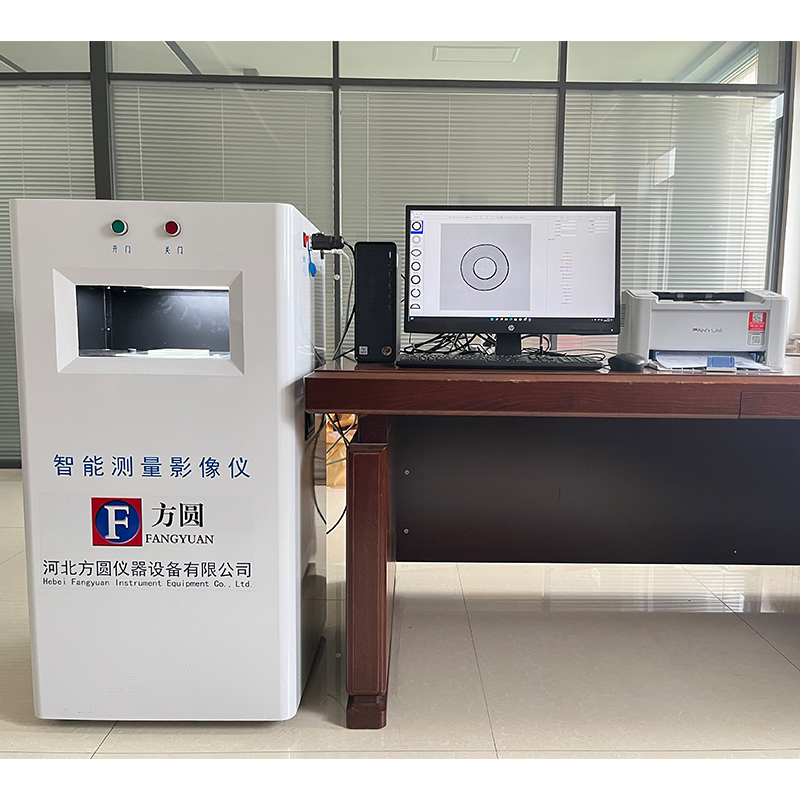

china tensile tester astm d412

1. Precision and Reliability Chinese manufacturers have increasingly adopted international standards in the design and production of their tensile testers. These machines are built with high precision load cells and robust frames to ensure accurate results consistently.

2. User-Friendly Interfaces Many modern tensile testers come with intuitive software that simplifies the process of setting up tests, monitoring results, and analyzing data. This user-friendly approach significantly reduces the learning curve for operators and enhances productivity in laboratories and production facilities.

3. Versatility While primarily designed for rubber testing per ASTM D412, many of these tensile testers can accommodate various materials, including plastics and composites. This versatility makes them a valuable investment for manufacturers who require multi-material testing capabilities.

4. Affordability One of the most significant advantages of sourcing tensile testers from China is cost-effectiveness. Manufacturers can access high-quality testing equipment at a fraction of the price compared to European or American counterparts, making it feasible for small and medium-sized enterprises to invest in the technology needed to ensure product quality.

Quality Assurance and Testing

While price is a notable factor, quality assurance is critical when selecting a tensile tester. Chinese manufacturers have made strides in quality control, often implementing ISO standards in their production processes. Before purchasing, it is advisable for companies to review certifications and user reviews of specific models to ensure they are investing in reliable equipment.

Regular calibrations and maintenance are also essential to keep tensile testers in optimal condition. Many reputable Chinese suppliers offer after-sales services, including calibration and training, helping users maintain the functionality and accuracy of their testing machines.

Conclusion

In conclusion, the China tensile tester adhering to ASTM D412 represents a blend of innovation, reliability, and affordability. As industries continue to demand stringent quality standards, the increased adoption of ASTM-compliant tensile testers from China will likely play a pivotal role in ensuring that rubber products maintain their integrity and performance. For manufacturers looking to enhance their testing capabilities, investing in these advanced machines could prove beneficial in meeting both domestic and international quality standards.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy