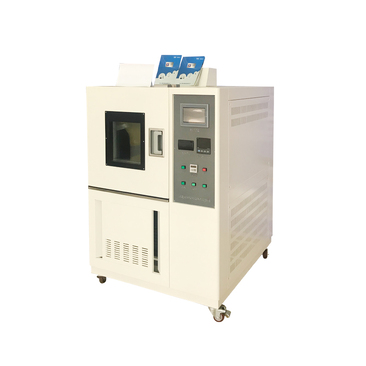

conductor resistance fixture

Understanding Conductor Resistance Fixtures Importance and Applications

The measurement of electrical resistance in conductors is a crucial task in various fields such as electronics, telecommunications, power generation, and many industrial applications. Accurate resistance measurements can reveal critical information about the quality and performance of electrical conductors. Conductor resistance fixtures are specialized tools designed for this purpose, facilitating highly accurate tests of resistance under various conditions. This article discusses the significance, design, and applications of conductor resistance fixtures, shedding light on their role in modern electrical systems.

What is a Conductor Resistance Fixture?

A conductor resistance fixture is a testing apparatus specifically engineered to measure the resistance of electrical conductors, including wires, cables, and other components. These fixtures typically provide a controlled environment where various parameters can be monitored and manipulated to ensure accurate resistance readings. The design of a fixture often includes features such as standardized connections, temperature control, and suitable materials to minimize interference and ensure consistent results.

Importance of Accurate Resistance Measurement

Accurate measurement of conductor resistance is essential for several reasons

1. Performance Verification In electrical systems, the performance of conductors can significantly impact overall efficiency. High resistance may indicate corrosion, poor connections, or material fatigue, which can lead to energy losses and reduce system reliability.

2. Safety Electrical systems must operate safely within specified limits. Excessive resistance can lead to overheating, fires, or equipment failure. Regular testing with a resistance fixture helps identify potentially dangerous conditions before they become critical.

3. Quality Control In manufacturing environments, ensuring that conductors meet specified resistance levels is vital for quality assurance. Conductors that do not meet the required resistance specifications may lead to product failures and increased warranty claims.

4. Compliance with Standards Various industry standards dictate the acceptable resistance levels for electrical components. Conductor resistance fixtures allow manufacturers and service providers to demonstrate compliance with these standards.

Design Features of Conductor Resistance Fixtures

Conductor resistance fixtures vary in design depending on their intended application

. However, several key features are common among themconductor resistance fixture

- Connection Terminals Standardized terminals or connectors are essential for easy integration with testing equipment and for ensuring reproducible connections during testing.

- Temperature Control Since resistance can change with temperature, many fixtures include methods for temperature measurement and control. This is particularly important in applications where conductors may operate under varying thermal conditions.

- Material Selection The materials used in the construction of the fixture are critical. Non-corrosive and low-resistance materials are often chosen to avoid introducing additional resistance that could skew test results.

- Calibration Features Some fixtures come equipped with calibration features that allow users to verify and adjust the measurement accuracy over time, ensuring that resistance readings are reliable.

Applications in Industry

Conductor resistance fixtures find their application across multiple sectors, including

1. Telecommunications In the telecommunications industry, resistance measurements are vital for assessing the integrity of transmission lines and ensuring minimal signal loss.

2. Electrical Utilities Utilities use resistance fixtures to test power transmission lines, transformers, and other equipment, ensuring they operate safely and efficiently.

3. Automotive Industry With the rise of electric vehicles, the need for accurate resistance testing in battery packs and charging systems has become critical, making resistance fixtures important in automotive testing laboratories.

4. Aerospace In aerospace applications, maintaining the integrity of electrical connections is paramount. Resistance testing ensures that components will perform reliably under the harsh conditions encountered in flight.

Conclusion

In conclusion, conductor resistance fixtures are indispensable tools for measuring the resistance of electrical conductors. Their role in ensuring safety, performance, quality control, and compliance with industry standards cannot be overstated. As electrical systems continue to evolve and grow in complexity, the importance of accurate resistance measurement will only increase, making innovative designs of resistance fixtures a focal point for research and development in the electrical engineering field. By leveraging these fixtures, industries can enhance the reliability and efficiency of their electrical systems, ultimately contributing to progress and innovation in technology.

-

uv-led-ultraviolet-crosslinking-technology-innovation-and-prospects

NewsAug.23,2025

-

ensuring-safety-and-compliance

NewsAug.23,2025

-

electrical-properties-testing-in-modern-applications

NewsAug.23,2025

-

universal-tensile-testing-machine-applications-in-modern-electrical-and-material-testing

NewsAug.23,2025

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy