Suppliers of Digital Projector Measurement Machines for Accurate Performance Evaluation

The Rise of Digital Projector Measuring Machines A Supplier's Perspective

In today's fast-paced technological landscape, precision and efficiency are paramount in manufacturing and quality control processes. One of the innovative solutions that have gained traction is the Digital Projector Measuring Machine (DPMM). This article explores the significance of DPMMs, the considerations for selecting a reliable supplier, and how these machines are revolutionizing the measurement processes in various industries.

Understanding Digital Projector Measuring Machines

Digital Projector Measuring Machines utilize advanced optical technology to project an enlarged image of an object onto a screen. This allows users to take precise measurements of complex geometries with ease and accuracy. Traditionally referred to as profile projectors, these machines have evolved significantly with the integration of digital technology, enhancing measurement accuracy while reducing turnaround times.

The operation of a DPMM generally involves placing a workpiece on a stage beneath a lens system. Light from the object is projected onto a screen, where its profile is visualized. Equipped with digital measuring systems, these machines can automatically calculate dimensions and tolerances, streamlining the inspection process. This capability is particularly beneficial for industries that require high-precision components, such as aerospace, automotive, and electronics.

The Need for Reliable Suppliers

Choosing the right supplier for DPMMs is critical to ensuring quality and efficiency in your operations. As a buyer, it is essential to assess various aspects of potential suppliers before making a decision.

1. Quality of Equipment The performance and longevity of a digital projector measuring machine heavily depend on its manufacturing quality. Reliable suppliers should offer machines built from high-grade materials and tested rigorously to meet industry standards.

2. Technical Support A good supplier should provide comprehensive technical support, including installation, calibration, and ongoing maintenance services. Quick resolution of issues minimizes downtime and maintains operational efficiency.

digital projector measuring machine supplier

3. Customization Options Different industries have varying measurement needs. A flexible supplier offers customization options for their DPMMs, ensuring that clients can tailor the machines to their specific applications.

4. Training and Resources Proper training on how to operate and maintain DPMMs is crucial. Suppliers that provide extensive training resources equip users with the skills needed to maximize the functionality and lifespan of the equipment.

5. Client Reviews and Testimonials Researching a supplier’s reputation through client feedback can provide insights into their reliability and the quality of their equipment. Positive testimonials can confirm the performance of the DPMMs and customer satisfaction levels.

Innovations and Applications

The digital projector measuring machine has found applications across multiple sectors due to its versatility. In the aerospace industry, for instance, precision is non-negotiable. Any deviation in measurements can lead to catastrophic failures, making the role of DPMMs essential in quality assurance processes.

In the automotive sector, DPMMs are used for inspecting intricate engine components and body parts, contributing to the overall safety and performance of vehicles. The electronics industry benefits from DPMMs by ensuring the accuracy of connectors and components that are crucial for device functionality.

Moreover, with the rise in Industry 4.0 and the Internet of Things (IoT), DPMMs are increasingly being integrated into automated production lines. Suppliers that offer DPMMs with connectivity features can streamline data collection and analysis, enabling businesses to adopt a more holistic approach to quality control.

Conclusion

As industries continue to pursue greater efficiency and precision, the demand for Digital Projector Measuring Machines is set to rise. Selecting a reliable supplier is key to harnessing the full potential of this technology. With the right machine, companies can achieve unparalleled accuracy in measurements, reduce waste, and maintain high standards in production quality. In a world where precision matters more than ever, investing in a DPMM from a trustworthy supplier can provide a significant competitive edge. Embracing this technology not only enhances processes but also ensures that businesses can meet the evolving demands of the market with confidence.

-

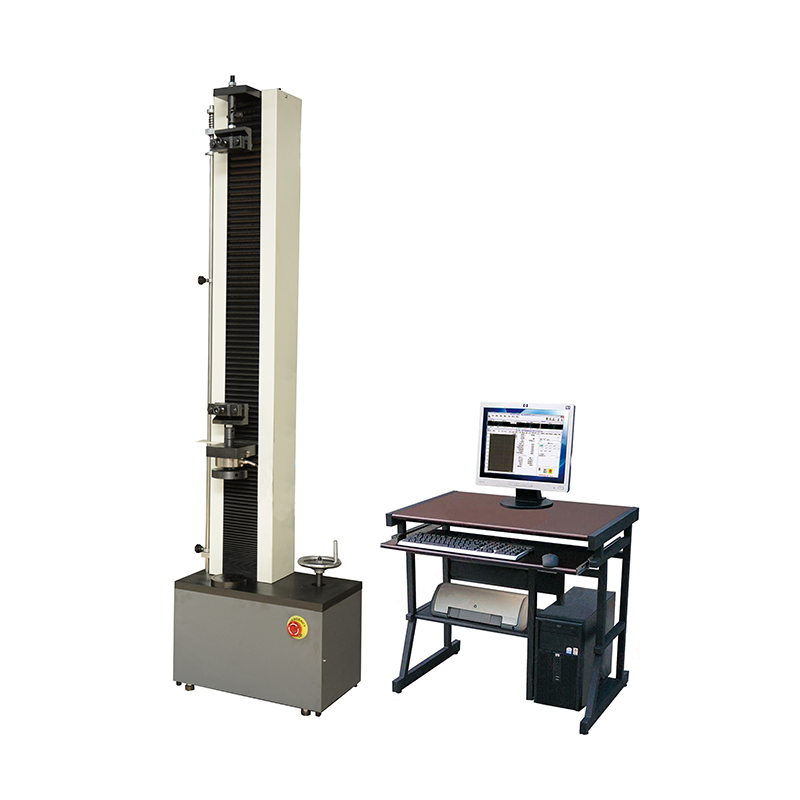

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy