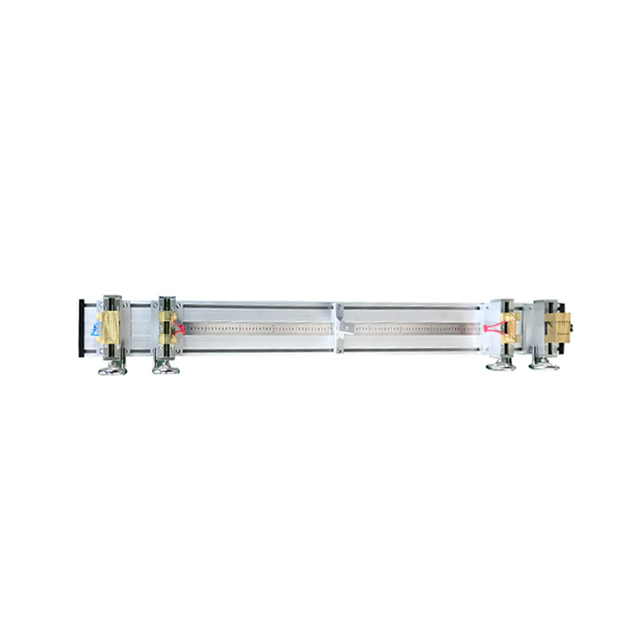

DQ-630/1200/2500 Conductor Resistance Clamp for Accurate Testing

Official Website: https://www.wirecabletest.com

Email: hb5117@163.com

Tel: +86-15232166507

Address: Building C5, Fangda Science District, Ningjin County, Hebei Province, China

Introduction: The Core of Electrical Testing – DQ-630/1200/2500 Conductor Resistance Clamp

In the evolution of the electrical cable and conductor testing industry, precision and reliability are paramount. The DQ-630/1200/2500 Conductor Resistance Clamp has become synonymous with high-performance conductor resistance measurements. This specialized resistance fixture, compliant with the IEC60468 standard, is meticulously designed for compatibility with industry-leading resistance meters, ensuring dependable results across a vast array of conductor types.

As global infrastructure investments rise and technologies like smart grids, e-mobility, and high-voltage transmission demand ever-higher quality standards (IEEE PES Technical Committee, Cable Systems), tools such as the DQ-630/1200/2500 Conductor Resistance Clamp from Hebei Fangyuan Instrument & Equipment Co.,Ltd. are setting new industry benchmarks.

Product Profile: DQ-630/1200/2500 Conductor Resistance Clamp

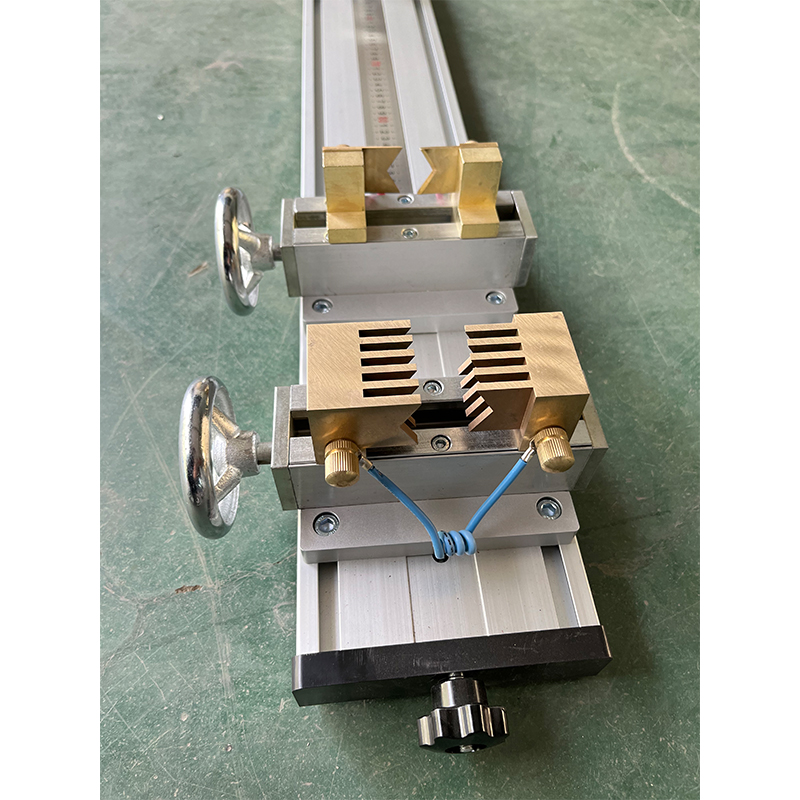

The DQ-630/1200/2500 Conductor Resistance Clamp is a highly versatile, precise resistance clamp used across testing laboratories, manufacturing units, and field installations. Its compatibility with major instruments such as QJ36, QJ44, and DJ57 resistance meters enables accurate measurement of conductor resistance for multiple cable types. The clamp is robust, features quick and secure fastening, and is constructed for long service life even in demanding industrial environments.

- Measurement Range: Accommodates a wide conductor size range (up to 2500mm2).

- Standard Compliance: Follows IEC60468 regulations for resistance testing.

- Fixture Adaptability: Enables interfacing with industry-standard resistance meters and diverse sample geometries.

- Applications: Power cables, aluminum/copper conductors, research validation, and production QC.

Industry Trends: The Role of Resistance Clamps in Modern Electrical Testing

The demand for highly accurate resistance measurement in electrical conductors has accelerated due to advancements in high-capacity grid transmission, EV charging infrastructure, and renewable energy installations (IEEE Xplore: “Cable Monitoring in Smart Grids - Techniques and Trends”, 2020). Laboratories and production lines require test fixtures that improve throughput, maintain consistency, and adhere to international standards. The DQ-630/1200/2500 Conductor Resistance Clamp stands out by offering measurable value in meeting these rigorous industry demands.

- Adoption of automated quality control in cable production lines.

- Implementation of IoT integrations for real-time resistance data capture.

- Widespread globalization of testing standards (IEC, ANSI/IEEE).

- Heightened focus on safety compliance and traceable calibration routines.

Technical Parameter Table: DQ-630/1200/2500 Conductor Resistance Clamp

| Model | Suitable Conductor Cross-Section (mm2) | Applicable Conductor Type | Resistance Measuring Range (μΩ~Ω) | Instrument Compatibility | Fixture Material | Standard |

|---|---|---|---|---|---|---|

| DQ-630 | up to 630 | Copper, Aluminum | 1 μΩ ~ 100 Ω | QJ36, QJ44, DJ57 | Nickel-plated Brass, Insulation Polymer | IEC60468 |

| DQ-1200 | up to 1200 | Copper, Aluminum | 1 μΩ ~ 100 Ω | QJ36, QJ44, DJ57 | Nickel-plated Brass, Insulation Polymer | IEC60468 |

| DQ-2500 | up to 2500 | Copper, Aluminum | 1 μΩ ~ 100 Ω | QJ36, QJ44, DJ57 | Nickel-plated Brass, Insulation Polymer | IEC60468 |

Data Visualization: Advanced Analysis of DQ-630/1200/2500 Conductor Resistance Clamp Technical Parameters

Application Scenarios: Maximizing Value Across the Power Sector

- Laboratory Testing: Academic, R&D, and accredited test labs require repeatable and precise measurements as per global standards. The robust construction of the DQ-630/1200/2500 Conductor Resistance Clamp prevents mechanical drift, ensuring confidence in test results.

- Manufacturing Quality Control: Cable factories integrate resistance clamps into QC cells, confirming product conformity prior to batch release.

- Field Commissioning: On-site engineers employ the clamp to validate conductor installation integrity, facilitating fast troubleshooting.

- Custom Projects: Utilities and special cable builders depend on tailor-fitted clamps for unique cross-sections or composite conductors.

Professional FAQ: Key Terms Surrounding the DQ-630/1200/2500 Conductor Resistance Clamp

Technical FAQ

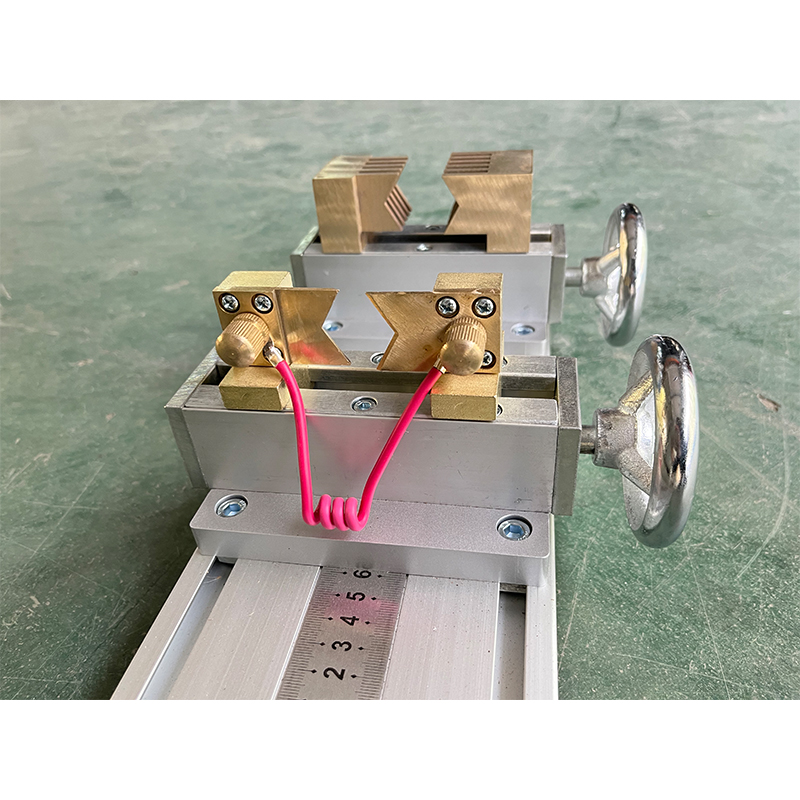

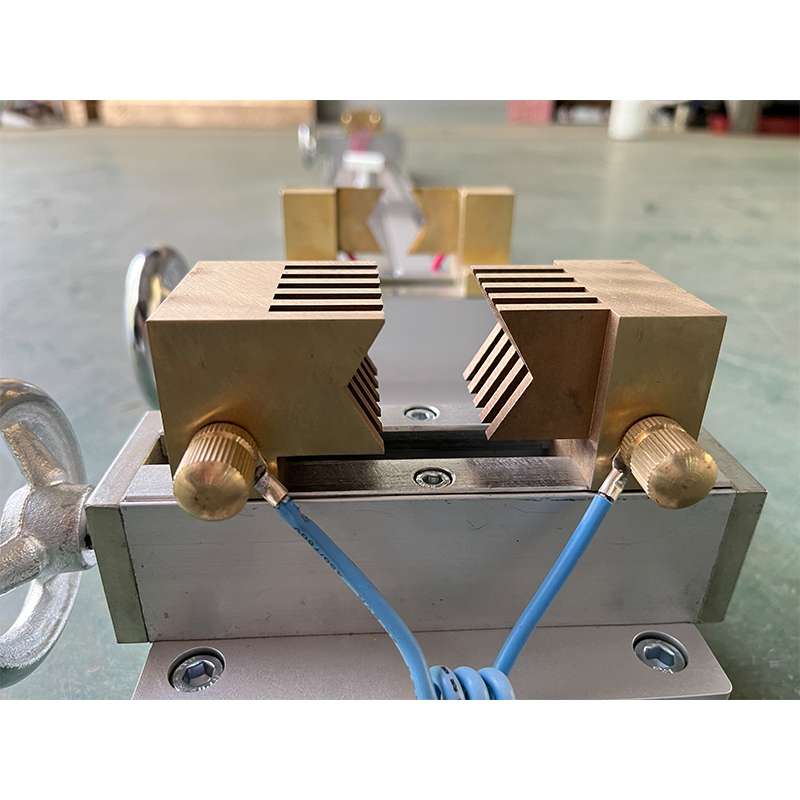

- 1. What material is used in the clamp’s current pathway?

- Nickel-plated brass is utilized for the main current-carrying components due to its superior conductivity and corrosion resistance, ensuring stable readings over years of use.

- 2. What is the applicable range of conductor size?

- The DQ-630/1200/2500 Conductor Resistance Clamp supports cross-sections up to 2500mm2, covering both standard and extra-large power cables.

- 3. How is measurement conformity assured?

- The clamp is IEC60468-compliant, and production bonds are traceable to calibration certificates, ensuring repeatable, auditable test results.

- 4. What types of resistance meters are compatible?

- It’s compatible with leading resistance meters such as QJ36, QJ44, DJ57, and others in the precision measurement sector.

- 5. Does the fixture support both copper and aluminum?

- Yes, the fixture is optimized for copper and aluminum conductors by form factor and contact electrode design.

- 6. What are the installation requirements?

- No permanent installation is necessary. The clamp is portable, employing a quick-lock and insulated base structure that allows safe and reversible attachment.

- 7. How often should the device be calibrated?

- Annual calibration is recommended, or upon signs of mechanical wear, in accordance with QC/QA manuals and industry best practices (National Grid Standard: Instrumentation QM).

Why Choose Hebei Fangyuan Instrument & Equipment Co.,Ltd. for Your Conductor Resistance Testing?

- Expertise: 20+ years pioneering cable and wire testing instruments, partnering with global utilities and laboratories.

- Authoritativeness: ISO-certified manufacturing and R&D, fully complied with domestic and international measurement standards.

- Trustworthiness: Thousands of successful installations, with testimonials from quality managers and technical directors worldwide.

- Ongoing Technical Support: Direct-from-factory aftersales, training, and remote calibration guidance.

- Comprehensive Product Range: From resistance clamps to voltage withstand testers — full spectrum, one source.

References & Further Reading

“Robustness in Clamp Meter Designs for Modern Power Systems”, IEEE Transactions on Instrumentation and Measurement, 2022

“Latest Standards and Practices for Cable Testing Fixtures”, IEEE Power & Energy Society Forums, 2023

“Calibration Traceability in Electrical Testing Labs”, Cable & Wire International Journal

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy