Manufacturer of Constant Temperature Tester for Measuring Conductor Resistance and Performance Evaluation

Understanding Conductor Resistance Constant Temperature Testers A Guide to Manufacturers and Applications

In the field of electrical engineering and materials testing, the precise measurement of conductor resistance is crucial for ensuring the quality and reliability of electrical components. One of the most effective tools for achieving accurate resistance measurements is the Constant Temperature Tester, specifically designed for conductor resistance testing. This article explores the importance of these testers, their applications, and what to look for when selecting a manufacturer.

The Importance of Conductor Resistance Testing

Conductor resistance tests are paramount in applications where the resistance of electrical conductors can significantly impact performance. In industries such as power generation, telecommunications, and electronics, a higher resistance can lead to energy loss, overheating, and equipment malfunction. Therefore, it is imperative to use reliable testing equipment that can measure resistance under controlled temperature conditions.

Constant temperature testers mitigate the effects of temperature fluctuations on resistance measurements. By maintaining a stable environment, these testers ensure accurate and repeatable results that reflect only the conductor's inherent properties. This feature is particularly vital as temperature can significantly affect the resistivity of materials, which can lead to erroneous conclusions if not properly accounted for.

Applications of Constant Temperature Testers

Constant temperature testers find their applications in various sectors. In the electrical manufacturing industry, they are used to assess the quality of wires and cables, ensuring that they meet industry standards for conductivity and resistance. In research laboratories, these testers allow scientists to investigate the properties of new materials and conduct experiments that require precise measurements.

Additionally, maintenance teams in power plants and substations utilize these testers to regularly check the resistance of grounding systems and connections

. This regular maintenance helps prevent potential failures and ensures the safety and efficiency of electrical installations.Selecting the Right Manufacturer

conductor resistance constant temperature tester manufacturer

When choosing a constant temperature tester, selecting the right manufacturer is critical. The manufacturer should prioritize reliability, accuracy, and innovative technology in their testing devices. Here are some key factors to consider

1. Reputation and Experience Look for manufacturers with a proven track record in producing high-quality testing equipment. Established companies often have more experience in refining their products and addressing customer needs.

2. Product Range A manufacturer offering a wide range of models can indicate their expertise in the field. This variety allows customers to choose devices that best meet their specific testing requirements.

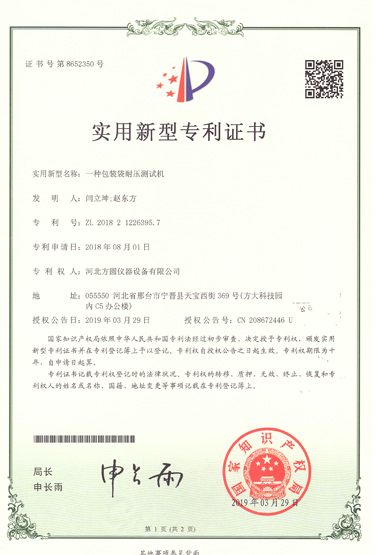

3. Calibration and Certification Ensure that the manufacturer provides calibration services and certification for accuracy. Regular calibration is vital to maintaining the precision of measurement devices, and certified products give users confidence in their reliability.

4. Technical Support and Training Quality manufacturers often provide comprehensive support and training to their customers. This assistance is essential for personnel who need guidance in utilizing the equipment effectively and interpreting the results.

5. Innovation and Technology Manufacturers that invest in research and development tend to offer advanced features, such as automated measurement processes and integration with data management systems. These innovations can enhance the efficiency and effectiveness of testing procedures.

Conclusion

Conductor resistance constant temperature testers are essential tools for ensuring the quality and reliability of electrical components across various industries. Selecting the right manufacturer is crucial to obtaining high-quality testing equipment that meets the specific needs of your applications. By considering factors such as reputation, product range, calibration services, technical support, and innovation, you can make an informed decision that contributes to your organization’s success in maintaining electrical safety and efficiency.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy