Measuring Equipment Solutions for Efficient Cable Manufacturing and Quality Control

Measuring Machines for Cable Manufacturing A Vital Investment for Quality Assurance

In today’s competitive manufacturing landscape, ensuring the quality of products is paramount. This is especially true for the cable industry, where the reliability and performance of cables are critical for their applications in various sectors including telecommunications, construction, and automotive. As a result, investing in advanced measuring machines is essential for cable manufacturers to meet stringent quality standards, enhance efficiency, and ultimately, achieve customer satisfaction.

Measuring Machines for Cable Manufacturing A Vital Investment for Quality Assurance

The use of automated measuring machines has revolutionized the quality control process in cable production. Unlike manual measuring methods, automated systems provide high precision and repeatability, which are critical for maintaining consistency. These machines can quickly process large quantities of cables, allowing manufacturers to conduct thorough inspections without slowing down production. This not only saves time but also reduces labor costs, making the entire operation more efficient.

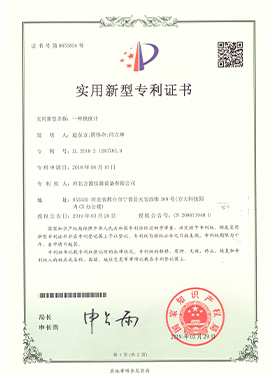

measure machine for cables company

One of the most significant advancements in measuring technology is the introduction of non-contact measurement systems. These systems use laser or optical sensors to capture data on cable dimensions and characteristics without exerting any physical force on the product. This is particularly advantageous for sensitive materials that may bend or deform under pressure. Furthermore, non-contact methods can measure multiple parameters simultaneously, offering a comprehensive evaluation of the cable's quality.

In addition to enhancing measurement precision, modern measuring machines are equipped with advanced data analysis software. This software allows for real-time monitoring and assessment of the production process, providing valuable insights into trends and potential issues. With this data, manufacturers can optimize their production lines, identify areas for improvement, and make informed decisions to enhance product quality. It also facilitates compliance with international standards, which are increasingly important in the global market.

Moreover, investing in measuring machines can foster innovation within the cable manufacturing industry. By ensuring the highest quality of cables, manufacturers can explore new applications and expand their product range. High-performance cables are essential for emerging technologies such as renewable energy systems, electric vehicles, and smart grids. Measuring machines not only ensure that existing products meet required standards but also support research and development efforts for new, high-tech cable solutions.

In conclusion, the investment in measuring machines for cable manufacturing is not merely a choice but a necessity for companies aiming to thrive in a challenging market. By adopting cutting-edge technology for quality assurance, manufacturers can improve product reliability, enhance efficiency, and meet the evolving demands of consumers. As the cable industry continues to grow and innovate, the importance of precise measurement will only become more pronounced, making measuring machines an indispensable part of the manufacturing process.

-

Reliable Performance Testing with Advanced Aging Chamber Solutions

NewsAug.23,2025

-

Advancing Precision with Profile Projector Technology

NewsAug.23,2025

-

UV-LED Ultraviolet Crosslinking Technology: Innovation and Prospects

NewsAug.23,2025

-

Ensuring Safety and Compliance

NewsAug.23,2025

-

Electrical Properties Testing in Modern Applications

NewsAug.23,2025

-

Universal Tensile Testing Machine Applications in Modern Electrical and Material Testing

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy