smoke density tester factory

Smoke Density Tester Factory Crafting Precision in Testing Equipment

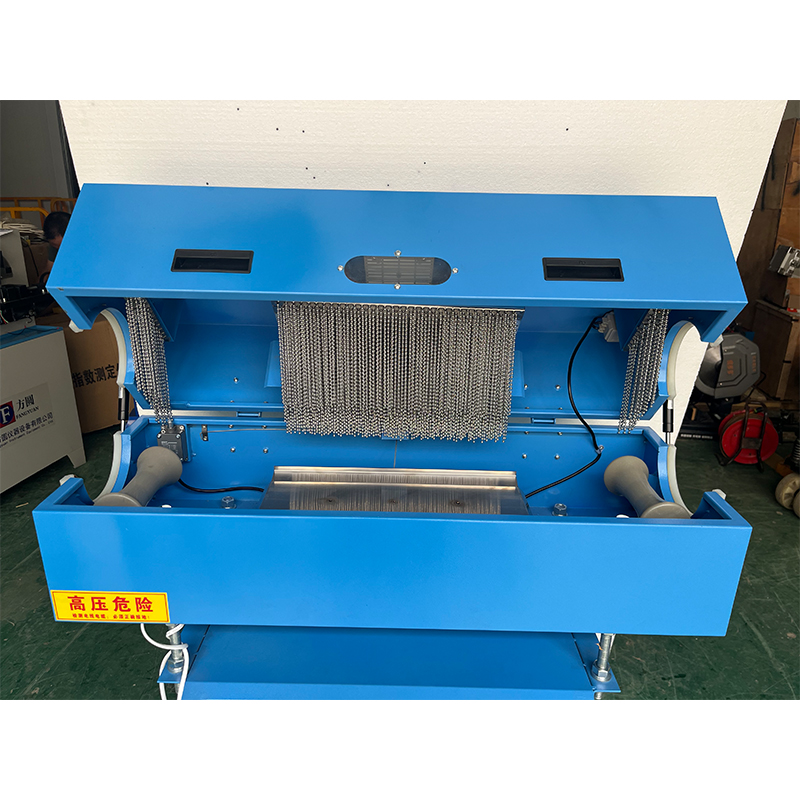

In the ever-evolving landscape of industrial testing equipment, the smoke density tester factory stands out as a critical hub of innovation and quality assurance

. These specialized facilities are dedicated to producing high-precision instruments essential for evaluating the smoke density of various materials, particularly in fields such as construction, automotive, and aerospace.Smoke density testing is imperative for understanding how materials react in fire conditions. By measuring the amount of smoke produced when a substance burns, these tests help assess its flammability and overall safety. Regulations in many industries mandate stringent testing to ensure that materials used do not contribute excessive smoke during combustion, which can impair visibility and contribute to harmful smoke inhalation.

The smoking density tester factory utilizes advanced technologies and state-of-the-art engineering to create devices that deliver accurate and reliable results. The production process begins with meticulous design, where engineers collaborate to develop equipment that meets international standards. These standards often include criteria set by organizations such as ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization).

Once the design phase is complete, materials are carefully selected for durability and performance. High-quality components are crucial, as they directly impact the accuracy of the measurements. The smoke density testers must be able to withstand various environmental conditions while providing consistent results. This is achieved through rigorous quality control checks throughout the manufacturing process.

smoke density tester factory

In addition to producing standard testing equipment, smoke density tester factories often offer customized solutions tailored to the specific needs of their clients. This adaptability allows industries with unique requirements to obtain testing equipment that meets their individual criteria, enhancing the testing process and ensuring compliance with safety regulations.

A significant aspect of the smoke density tester factory's operations is the emphasis on research and development. Continuous innovation is vital in today's competitive market. These manufacturers invest in R&D to improve existing products and develop new technologies that enhance testing accuracy and efficiency. This focus on innovation keeps them at the forefront of the industry and ensures they can meet the ever-changing demands of sectors that require smoke density testing.

Moreover, the factory plays a vital role in training and educating users about the proper operation of smoke density testers. Knowledgeable staff provide comprehensive training sessions, helping clients understand the intricacies of their testing equipment and how to accurately interpret the results. This commitment to education helps to minimize errors and maximize the efficacy of testing processes across various industries.

In conclusion, the smoke density tester factory is essential for ensuring the safety and compliance of materials used in various applications. By combining advanced technology, rigorous quality control, and a commitment to innovation, these factories produce reliable testing instruments that play a critical role in fire safety. As industries continue to prioritize safety and regulatory compliance, the importance of high-quality smoke density testing equipment cannot be overstated.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy