Top Suppliers for Universal Tensile Testing Machines in the Industry

The Importance of Universal Tensile Testing Machines and Selecting the Right Supplier

Universal tensile testing machines are essential tools used in various industries to evaluate the tensile strength, ductility, and other mechanical properties of materials. These machines provide valuable data that help engineers and manufacturers ensure product quality and compliance with industry standards. As the demand for high-quality materials continues to rise, selecting the right supplier for universal tensile testing machines has become increasingly important.

Understanding Universal Tensile Testing Machines

Universal tensile testing machines apply a controlled tension or compression to a material specimen until it deforms or fractures. The results obtained from these tests are crucial in understanding how a material behaves under stress and can help predict its performance in real-world applications. Key aspects measured during tensile testing include ultimate tensile strength, yield strength, elongation, and reduction of area. These parameters are essential for industries such as construction, automotive, aerospace, and manufacturing, as they directly influence safety and performance.

Key Features to Look for in a Universal Tensile Testing Machine

When selecting a tensile testing machine, several factors should be considered

1. Capacity Different applications require machines with varying load capacities. It's critical to choose a machine that can handle the maximum strength of the materials you intend to test.

2. Accuracy Precision is vital when measuring material properties. Look for machines equipped with high-quality sensors and data analysis software to ensure reliable and repeatable results.

3. Ease of Use The machine should have an intuitive interface and user-friendly software for ease of operation. This feature is particularly important in environments where multiple users may operate the equipment.

4. Versatility Choose a machine that can perform various types of tests, including tensile, compression, flexural, and shear tests. This versatility can save time and resources in the long run.

universal tensile testing machine suppliers

5. Maintenance and Support Consider suppliers that offer excellent customer support, including training, maintenance services, and readily available spare parts. A reliable supplier can significantly impact the longevity and performance of your testing machine.

Finding the Right Supplier

Choosing the right supplier for a universal tensile testing machine is crucial for ensuring that you receive a high-quality product that meets your specific needs. Here are some steps to help you in your search

1. Research and Compare Start by researching various suppliers, their product ranges, and customer reviews. Compare their offerings, focusing on the machines' specifications and features.

2. Industry Experience Look for suppliers with a proven track record in the testing machinery industry. Suppliers with extensive experience are more likely to understand your specific requirements and provide tailored solutions.

3. Customization Options Some projects may require unique testing setups. Suppliers that offer customization options can better meet your specific needs and provide machines equipped with the latest technology.

4. Network and Recommendations Engage with industry professionals, attend trade shows, and seek recommendations from peers. Networking can lead you to reputable suppliers and provide insights into their reliability and service.

5. Warranty and Service Agreements Ensure that the supplier provides a solid warranty and service agreement. This offers peace of mind and protection for your investment.

Conclusion

Universal tensile testing machines are integral to ensuring that materials meet the necessary safety and performance standards. Selecting the right supplier is crucial in obtaining a machine that not only fulfills your testing requirements but also provides support throughout its lifecycle. By considering the features, conducting thorough research, and relying on recommendations, you can make an informed decision that will enhance your material testing capabilities and overall production quality.

-

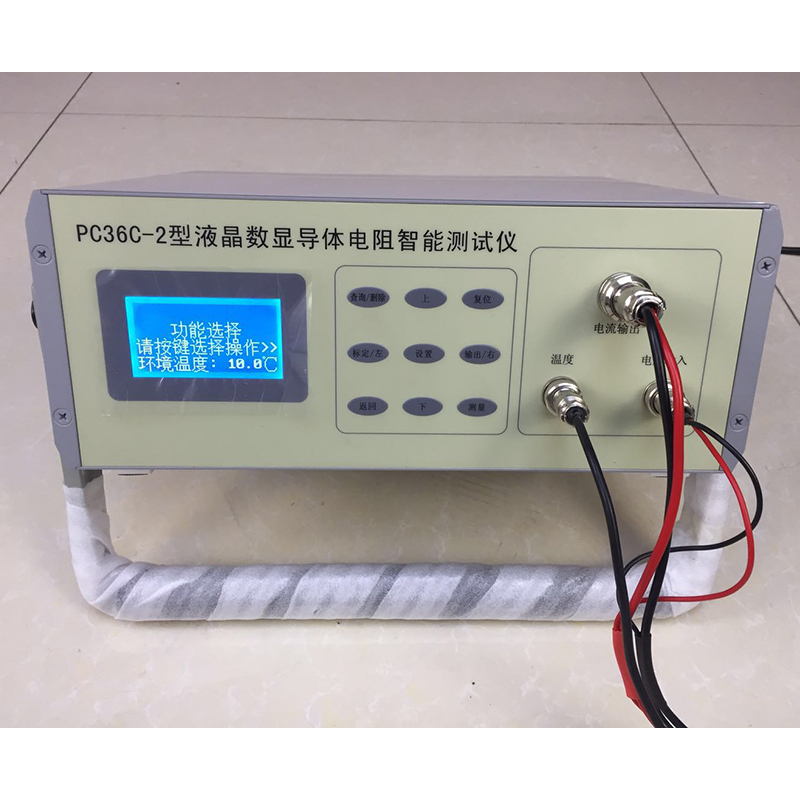

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy