Top Manufacturers of Aging Ovens for Reliable Thermal Testing Solutions

The Evolution of Aging Ovens A Closer Look at Manufacturers

Aging ovens play a crucial role in various industries, especially in the realm of manufacturing and testing electronic components. As technology advances, so does the demand for precision and reliability in these ovens. Manufacturers are stepping up to provide enhanced capabilities, ensuring that aging ovens meet the rigorous standards set by modern industries.

What Are Aging Ovens?

Aging ovens are specialized devices used to simulate long-term exposure conditions for electronic components and materials. By subjecting these components to elevated temperatures and controlled environments, manufacturers can evaluate their lifespan and durability over time. This process is essential for quality assurance, as it helps identify potential failures before products reach the consumer market.

The Importance of Quality Manufacturing

The performance of aging ovens is directly tied to the quality of their construction and design. Manufacturers must focus on several key aspects, including temperature control, insulation, and airflow. Precision engineering ensures that the ovens can maintain consistent environments, minimizing any variables that might skew test results. Furthermore, implementing state-of-the-art technology allows for better monitoring and data collection throughout the aging process.

Innovations in Aging Oven Technology

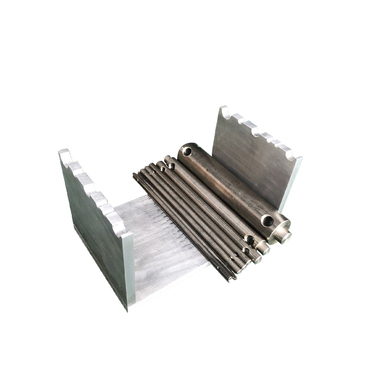

aging ovens manufacturer

Recent advancements in oven technology have led to the development of smarter, more efficient systems. Modern aging ovens are equipped with advanced temperature sensors and digital controls, which provide real-time monitoring and automation capabilities. This not only enhances accuracy but also reduces the risk of human error. Additionally, manufacturers are now using materials that provide better insulation, thereby improving energy efficiency and reducing operational costs.

Sustainability Considerations

With the growing emphasis on sustainability, many aging oven manufacturers are integrating eco-friendly practices into their production processes. This includes using recyclable materials and designing ovens that consume less energy. By focusing on sustainability, manufacturers not only contribute to environmental efforts but also appeal to a broader market increasingly concerned with the ecological impact of their purchases.

Future Trends in Aging Ovens

Looking ahead, the aging oven market is poised for further innovation. As the electronics industry continues to evolve, manufacturers will need to adapt their products to accommodate new materials and technologies. This may involve developing aging ovens that can handle a wider array of temperature and humidity levels or integrating machine learning algorithms for predictive maintenance and improved efficiency.

Conclusion

The role of aging ovens and their manufacturers in the electronics testing industry cannot be overstated. With ongoing technological advancements and a commitment to quality and sustainability, the future of aging ovens looks promising. As manufacturers continue to innovate, they will undoubtedly enhance the reliability and efficiency of the testing processes, ultimately benefiting the entire electronics sector and ensuring safer, more reliable products for consumers.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy