Cable Hot Set Testing Procedures for Manufacturing Facilities and Quality Assurance

Cable Hot Set Testing Ensuring Quality and Safety in Manufacturing

In the rapidly evolving world of electrical components, the reliability and safety of cables are paramount. One critical evaluation process that manufacturers employ to ensure that their products can withstand extreme conditions is the cable hot set testing. This testing method plays a significant role in various industries, including automotive, aerospace, and construction. This article will explore the significance of cable hot set testing, the intricacies of the process, and its importance in manufacturing.

Understanding Cable Hot Set Testing

Cable hot set testing is a procedure designed to evaluate the ability of cable materials, particularly insulation and sheath compositions, to withstand elevated temperatures and prolonged heat exposure. The test typically involves exposing a specimen to specific temperatures while applying a tensile load. This process helps determine various mechanical and thermal properties of the cables, including elongation, tensile strength, and resistance to deformation.

The hot set test is vital because cables are often subjected to extreme environments where temperature fluctuations are prevalent. Whether in industrial machinery or automotive applications, the integrity of cable insulation is crucial. Inadequate performance can lead to catastrophic failures, electrical fires, or operational downtime.

The Testing Process

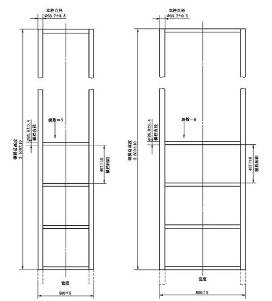

The cable hot set testing process involves several key steps

1. Sample Preparation Manufacturers begin by preparing standardized cable samples according to industry specifications. These samples must represent the various types of cables that will undergo testing.

2. Heat Application The prepared samples are then placed in a hot set testing apparatus that can maintain controlled high temperatures. The temperature typically ranges from 200°C (392°F) to 220°C (428°F), mimicking the upper limits that cables may encounter in real-world applications.

3. Tensile Load During the heating process, a tensile load is applied to the samples. This load can simulate the stresses generated during installation and operation.

cable hot set testing factories

4. Duration The cable specimens are subjected to the high temperature and tensile load for a specified duration—often ranging from 5 to 30 minutes—depending on the required standards.

5. Cooling and Measurement After the heat exposure period, samples are allowed to cool to room temperature. Measurements are then taken to assess the amount of deformation and any changes in mechanical properties.

6. Data Analysis Finally, the data collected is analyzed to determine if the cables meet industry standards for thermal and mechanical performance. Any deviations from the established limits signal failures that need to be addressed in the manufacturing process.

Importance of Hot Set Testing

The significance of cable hot set testing in manufacturing cannot be overstated. Firstly, it ensures compliance with national and international safety standards. Allegiance to such standards is not only beneficial for market access but also essential for consumer safety.

Secondly, this testing process aids in identifying inferior or faulty materials before they are deployed in critical applications. By detecting weaknesses in the early stages of production, manufacturers can preemptively address defects, reducing the risk of recalls or lawsuits due to safety concerns.

Furthermore, cable hot set testing can contribute to improved design. Manufacturers can use the data gathered during testing to enhance materials and production techniques, leading to innovation and improved products that meet the evolving demands of industries.

Conclusion

As industries become increasingly reliant on the safety and efficiency of electrical cables, the importance of meticulous quality control, including cable hot set testing, becomes evident. This testing not only safeguards manufacturers against potential liabilities but also fosters trust among consumers. By ensuring that cables can withstand the heat, both literally and figuratively, manufacturers can deliver products of the highest quality, ready to tackle the challenges of modern applications. As technology progresses and applications evolve, the need for rigorous testing methodologies like the hot set test will continue to grow, underscoring its role as a cornerstone of quality assurance in cable manufacturing.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy