cable thermal elongation test

Understanding the Cable Thermal Elongation Test

In the realm of electrical engineering and materials science, understanding the behavior of materials under varying thermal conditions is crucial. One significant aspect of this is the thermal elongation of cables, particularly those used in power transmission and distribution. The Cable Thermal Elongation Test is a method designed to evaluate how cables expand and contract with temperature changes, providing valuable data for performance and safety assessments.

Importance of Thermal Elongation Testing

The ability of a cable to withstand temperature changes is critical for its longevity and operational efficiency. Cables are subjected to various environmental conditions, and fluctuations in temperature can lead to significant physical changes in their materials. If a cable expands beyond its planned dimensions, it can result in stress on the connectors and surrounding structures, potentially leading to failure. Thus, assessing thermal elongation is essential not only for ensuring the reliability of the cable but also for safeguarding the infrastructure they support.

The Testing Process

The cable thermal elongation test typically involves several key steps

1. Preparation of Specimens Cables are first prepared as per standard specifications, ensuring they represent typical installations. This includes defining the length and conditions under which the test will occur.

2. Temperature Control To simulate various operating conditions, the cables are subjected to a controlled temperature environment. High and low temperatures are applied to assess how the cable behaves across a range of thermal conditions.

3. Measurement of Elongation As the temperature changes, precise measurements are taken to assess the elongation of the cable. This is often done using specialized equipment, such as extensometers, which can provide accurate readings.

4. Data Analysis The results are analyzed to determine the thermal elongation coefficient, which is crucial for predicting how the cable will perform under real-world conditions.

cable thermal elongation test

5. Reporting Finally, the results are documented in a comprehensive report that details the conditions of the test, the methodologies applied, and the findings. This data is invaluable for manufacturers and engineers in designing cables that can withstand thermal stress.

Applications of Thermal Elongation Data

The data obtained from thermal elongation tests can be applied in various ways. Firstly, it assists manufacturers in selecting appropriate materials that can tolerate temperature changes without significant elongation or contraction. This is particularly important for high-voltage cables and those installed in extreme climates.

Moreover, engineers utilize this information in the design phase to create cable systems that account for thermal expansion. By understanding the expected elongation, they can design connectors and support systems that accommodate these changes, significantly reducing the risk of failures.

Industry Standards and Regulations

Cable manufacturers and engineers are guided by various industry standards that dictate the requirements for thermal elongation testing. These standards ensure that cables meet minimum performance criteria before they are deployed in the field. Compliance with these regulations is not only crucial for market acceptance but also for meeting safety requirements established by regulatory bodies.

Failure to adhere to these standards can lead to severe consequences, including infrastructure breakdowns or safety hazards. Therefore, conducting thorough thermal elongation tests and meeting all applicable standards is a responsibility that manufacturers take seriously.

Concluding Thoughts

In conclusion, the Cable Thermal Elongation Test is a fundamental practice that significantly enhances the reliability and safety of electrical systems. As the demand for robust and efficient power transmission continues to grow, so does the need for comprehensive testing methodologies like thermal elongation assessments. It is a critical step in ensuring that the cables used today can stand up to the test of time and temperature, fostering a safer and more efficient electrical infrastructure for the future. Understanding the implications of thermal elongation will allow engineers and manufacturers to craft solutions that not only perform well but also last longer under varying conditions. In an era where energy demands are increasing, the importance of reliable cable systems cannot be overstated.

-

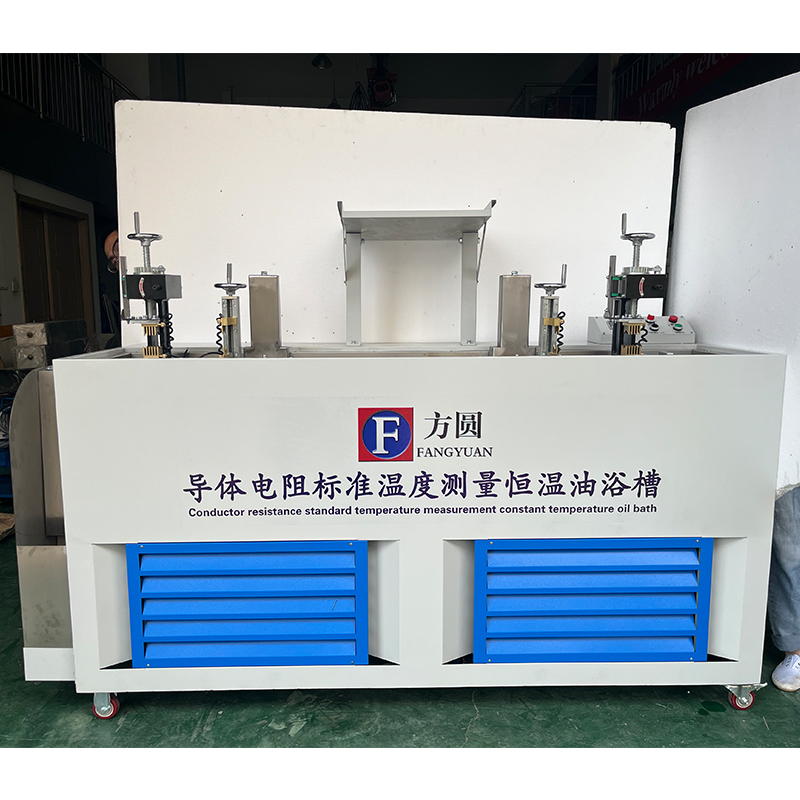

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy