clamp manufacturer

Understanding Clamp Manufacturers A Key Component in Industry and Crafts

Clamps are often viewed as simple tools, yet they play a crucial role across various industries, from manufacturing to construction to home improvement. At the core of this indispensable tool are clamp manufacturers, who design, engineer, and produce these devices with precision and reliability in mind.

Clamp manufacturers specialize in creating a multitude of different types of clamps, each tailored for specific applications. Common types include C-clamps, bar clamps, pipe clamps, and spring clamps, among others. Each type is designed for unique uses, such as securing materials together, holding components in place during assembly, or providing support in woodworking and metalworking tasks.

The process of clamp manufacturing involves several steps, starting from the design phase. Engineers and designers utilize advanced computer-aided design (CAD) software to develop prototypes that meet stringent specifications for strength and usability. Materials play a critical role in the function and durability of clamps. Manufacturers often use metals like steel or aluminum for their strength, while high-quality plastic is sometimes used for lightweight, less demanding applications.

Once the design is finalized, the production phase begins. This involves processes such as casting, forging, or machining, depending on the type of clamp being manufactured. For example, heavy-duty clamps may require forging to ensure they can withstand significant pressure and stress, while lighter clamps may be cast from high-grade plastic. Quality control is paramount during this phase; manufacturers conduct rigorous testing to ensure that each clamp meets safety and performance standards.

clamp manufacturer

Innovation within the clamp manufacturing sector has also led to the development of more advanced products. Features such as quick-release mechanisms, ergonomic handles, and adjustable pads enhance the usability of clamps, making them easier and more efficient to use. Additionally, some manufacturers focus on eco-friendly practices by using sustainable materials and minimizing waste during production processes.

The market for clamps is vast, with applications in numerous sectors. In construction, clamps are essential for safely holding scaffolding parts together, while woodworking enthusiasts rely on them for accuracy in joinery. In automotive manufacturing, clamps help secure components during assembly. Furthermore, with the rise of DIY culture, clamp manufacturers are catering to hobbyists and homeowners looking for affordable and effective tools for their personal projects.

A well-known trend among clamp manufacturers is the increasing emphasis on customization. Customers can now request specific sizes, colors, or features that cater to their individual needs. This flexibility not only enhances customer satisfaction but also enables manufacturers to better serve niche markets.

In conclusion, clamp manufacturers play a fundamental role in the functionality of various industries. Through continuous innovation and a commitment to quality, these manufacturers are ensuring that clamps remain indispensable tools for professionals and DIY enthusiasts alike. Whether you are building a structure, creating a piece of furniture, or engaging in a simple repair, the reliability of a well-made clamp is undeniable, demonstrating the critical importance of those who produce them.

-

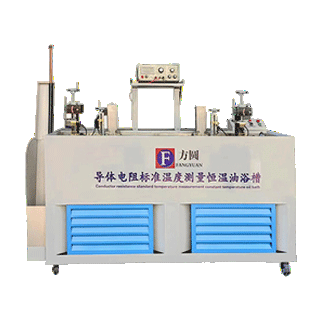

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy