conductor resistance test equipment factories

Understanding Conductor Resistance Test Equipment Essential for Electrical Testing

Conductor resistance test equipment plays a crucial role in the electrical industry. This specialized testing apparatus is designed to measure the resistance of conductive materials, ensuring that electrical systems operate efficiently and safely. With the increasing complexity of electrical installations and the demand for high performance, understanding the functionality and significance of this equipment becomes vital for engineers and technicians alike.

Importance of Conductor Resistance Testing

Conductor resistance testing is essential for several reasons. Firstly, resistance affects the overall performance of electrical systems. High resistance in conductors can lead to excessive heat generation, energy losses, and potential system failures. By measuring the resistance, professionals can identify issues such as corrosion, poor connections, or the degradation of materials over time.

Secondly, this testing helps in complying with industry standards and regulations. Various standards, such as those set by the Institute of Electrical and Electronics Engineers (IEEE) and the International Electrotechnical Commission (IEC), emphasize the need for regular testing of electrical installations. This ensures that the systems are safe for operation and reduces the risk of hazardous accidents.

How Conductor Resistance Test Equipment Works

Conductor resistance test equipment operates on the principle of Ohm's law, which states that the resistance (R) of a conductor is equal to the voltage (V) across it divided by the current (I) flowing through it

. Most modern devices utilize a four-wire method, which minimizes the impact of lead resistance and provides more accurate readings.The typical setup involves connecting the test leads to the conductor, generating a precise current, and measuring the resulting voltage drop. This data is then used to calculate the resistance, usually displayed in micro-ohms or milliohms. Advanced models also incorporate features such as automatic temperature compensation, data logging, and connectivity options for easy integration into digital systems.

Key Features to Look For

conductor resistance test equipment factories

When selecting conductor resistance test equipment, it is essential to consider several key features

1. Accuracy Look for devices with high accuracy levels, as even small deviations can lead to significant consequences in electrical performance.

2. User-Friendly Interface An intuitive interface with clear displays facilitates easy operation, especially in field conditions.

3. Portability For technicians who conduct tests on-site, lightweight and compact equipment is a practical choice.

4. Durability Given the environments in which testing often occurs, robust construction is crucial for the longevity of the equipment.

5. Integrated Software Some models come with software that allows for data analysis and reporting, making it easier to track historical performance and trends.

Conclusion

Investing in high-quality conductor resistance test equipment is essential for the reliability and safety of electrical systems. Regular testing not only ensures compliance with standards but also extends the lifespan of installations and optimizes performance. As technology evolves, so does the sophistication of testing equipment, offering enhanced features that support the ever-increasing demands of the electrical industry. For engineers and technicians, understanding and utilizing this equipment is paramount to maintaining efficient and safe electrical infrastructures.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

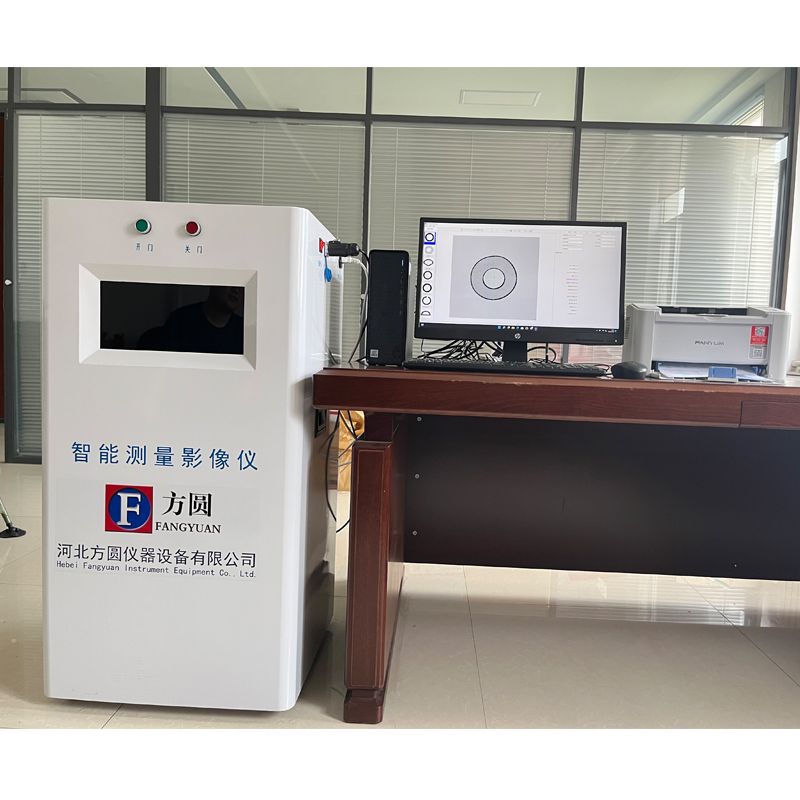

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy