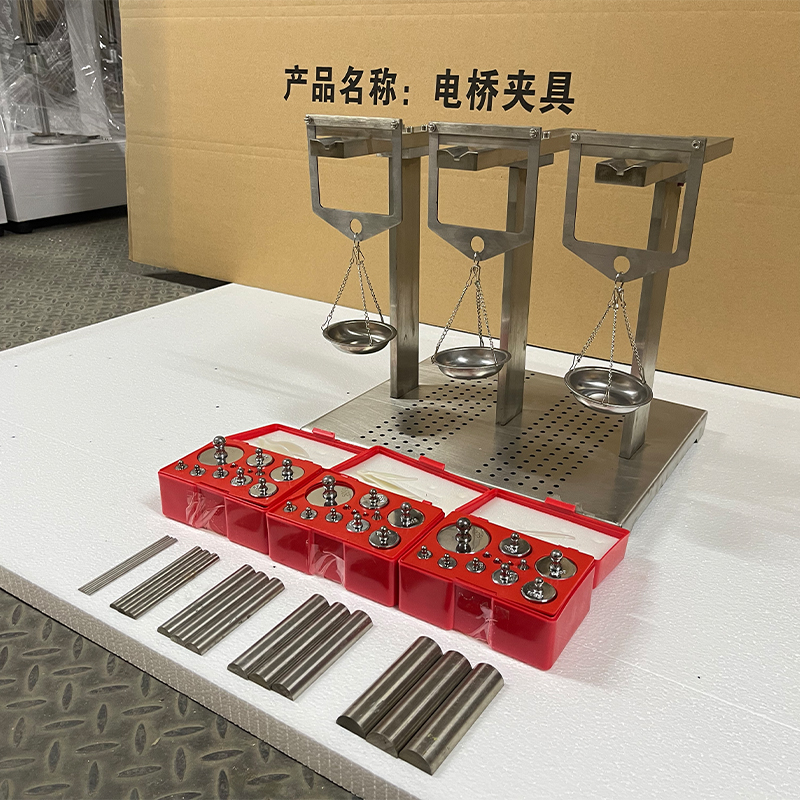

custom standard resistance tester

Custom Standard Resistance Tester Ensuring Precision in Electrical Measurements

In the realm of electrical engineering and maintenance, the accuracy of measurements is paramount. Among the critical tools that professionals rely on is the standard resistance tester. A custom standard resistance tester can enhance measurement precision, improve efficiency, and tailor functions to specific applications. This article explores the significance, components, applications, and advantages of using a custom standard resistance tester in various industries.

Understanding Standard Resistance Testing

Standard resistance testing is fundamental for various electrical applications, ensuring that devices adhere to prescribed resistance values. The resistance tester measures the electrical resistance of materials and components, often verifying compliance with industry standards. A standard resistance tester usually operates using the four-wire or Kelvin method, which eliminates the impact of lead resistance on readings — a vital factor for achieving high accuracy.

The Case for Customization

While off-the-shelf resistance testers can serve many purposes, they may not always meet the specific requirements of all applications. A custom standard resistance tester provides the flexibility to adapt the instrument to unique factors such as

1. Measurement Range Different applications require specific resistance ranges — from milliohms in power systems to megaohms in insulation testing. Custom testers can be designed to address specific measurement requirements effectively.

2. Environmental Conditions Certain industries, such as oil and gas or pharmaceuticals, may operate in extreme conditions that standard testers cannot withstand. Customized solutions can incorporate features such as rugged housings, temperature stability, and moisture resistance.

3. Integration with Existing Systems Engineers often demand compatibility with existing data management systems or reporting tools. Custom testers can be programmed to integrate seamlessly, providing analytics and traceability for compliance and quality assurance.

4. User Interface A user-friendly interface tailored to specific operators can enhance ease of use, reduce training time, and improve overall efficiency. Custom standard resistance testers can be designed with specific software applications, graphical displays, and control features that suit the operator’s needs.

Components of a Custom Standard Resistance Tester

A well-designed custom standard resistance tester typically includes various key components to ensure precision and usability

- High-Precision Resistors These are critical for establishing standard resistance values against which other components can be tested. High-quality materials and manufacturing processes eliminate drift and ensure long-term stability.

- Digital Display Unit An intuitive display that presents measurements clearly and accurately

. Modern devices also incorporate touch screens for ease of navigation.- Data Logging Capabilities Many industries demand record-keeping for compliance or quality assurance. Custom testers can include robust data logging features and connectivity for automated reporting.

custom standard resistance tester

- Calibration Features Incorporating self-calibration features ensures that the tester maintains accuracy over time. Users can quickly confirm the device's precision without external resources.

Applications Across Industries

Custom standard resistance testers find applications in various sectors, including

- Power Generation and Distribution Ensuring transformer winding continuity and verifying grounding systems. - Manufacturing Testing components like motors, solenoids, and relays to guarantee product reliability and quality.

- Telecommunications Verifying telecommunications connections and ensuring minimal resistance to signal flow.

- Research and Development Universities and labs employ custom testers in experimental setups for precision measurement in various projects.

The Advantages of Using a Custom Standard Resistance Tester

The benefits of utilizing a custom standard resistance tester cannot be overstated

1. Enhanced Precision Higher accuracy measurements can lead to reduced downtime and maintenance costs.

2. Increased Efficiency Custom features help streamline operations and reduce the time needed for testing.

3. Tailored Solutions Businesses can design testers that meet their exact specifications, enhancing workflow and productivity.

4. Long-Term Cost Savings Although the initial investment in a custom solution may be higher, the potential for increased efficiency and reduced errors often leads to significant long-term savings.

Conclusion

A custom standard resistance tester serves as an invaluable tool for various industries, ensuring precise measurements and compliance with standards. By understanding the unique requirements of each application, professionals can leverage tailored solutions to enhance their operations, ultimately leading to improved reliability and efficiency in their electrical systems. Embracing the technological advancements in this field aligns with the growing demand for accuracy and customization in modern engineering.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy