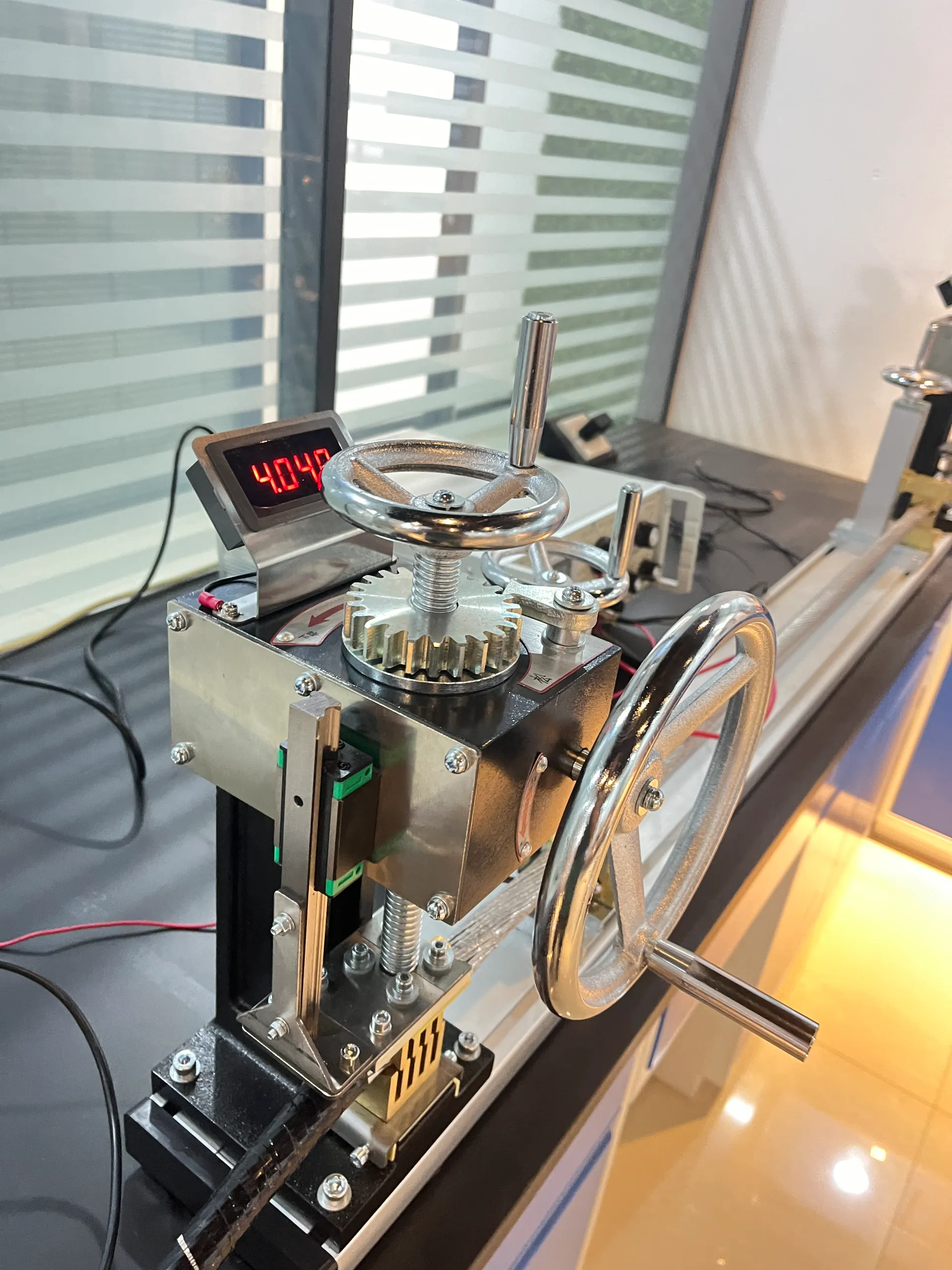

custom universal tensile testing machine

Custom Universal Tensile Testing Machine An Overview

In the realm of material testing, the importance of accurately assessing material properties cannot be overstated. As industries continue to evolve, the demand for reliable and precise testing equipment has grown significantly. One such essential piece of machinery is the universal tensile testing machine. This device plays a vital role in determining the tensile strength, elongation, and overall performance of materials, whether they are metals, plastics, or composites. With the rise of customization in industrial equipment, the custom universal tensile testing machine has become increasingly popular, catering to the specific needs of various industries.

A universal tensile testing machine typically comprises a load frame, control system, and measurement devices that work collaboratively to conduct tensile tests. The primary objective is to apply a controlled tensile load to a specimen until it fails, allowing engineers to gather crucial data about the material’s properties. However, off-the-shelf machines may not always meet the unique requirements of every industry or application, prompting the need for customized solutions.

Key Features of Custom Universal Tensile Testing Machines

One of the main advantages of opting for a custom universal tensile testing machine is the ability to tailor its features according to specific testing requirements. Here are some key aspects to consider when seeking a custom solution

1. Load Capacity Different materials exhibit varying degrees of tensile strength. A custom machine can be engineered to accommodate the specific load capacity required for testing particular substances, ranging from lightweight polymers to heavy-duty metals.

2. Testing Speed and Profile Manufacturers may require different testing speeds and methodologies based on industry standards or specific project needs. A customizable tensile testing machine allows users to adjust the speed of loading and select different testing profiles, facilitating compliance with various international testing standards.

custom universal tensile testing machine

3. Gripping Mechanisms The gripping mechanism is crucial in ensuring that the test specimen is held securely during testing. Customized grips can be designed to accommodate various shapes and sizes of materials, ensuring optimal performance and the prevention of slippage or premature failure.

4. Control Systems and Software Advanced control systems and data acquisition software are integral to the effective operation of a tensile testing machine. Custom solutions can incorporate state-of-the-art technology, including user-friendly interfaces and real-time data analysis tools that enable operators to monitor tests and analyze results efficiently.

5. Integration with Other Testing Methods Many industries perform multiple types of mechanical testing, such as compression, bending, or fatigue testing. A custom universal tensile testing machine can be designed to integrate seamlessly with other testing equipment, enhancing a laboratory's capability to conduct comprehensive material evaluations.

6. Compliance with Standards Custom machines can be engineered to comply with specific industry standards like ASTM, ISO, or DIN, ensuring that the test results are valid and can be used for regulatory or certification processes.

Conclusion

The significance of material testing in product development and quality assurance cannot be overlooked. A custom universal tensile testing machine provides a flexible and necessary solution to meet the rigorous demands of diverse industries. By allowing customization in terms of load capacity, testing profiles, grips, control systems, and integration with other testing methods, this equipment becomes an invaluable asset for engineers and researchers.

Moreover, as industries strive for innovation and superior quality, the role of custom tensile testing machines will only continue to expand. By investing in tailored solutions, companies can ensure that they are equipped to understand the properties of the materials they use, paving the way for advancements in product design and development. In an ever-changing industrial landscape, the custom universal tensile testing machine stands out as a critical investment for those seeking precision, reliability, and adaptability in material testing.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy