Dumbbell Cutters Heavy-Duty Steel Cutting Tools & Custom Solutions

- Overview of Dumbbell Cutter Technology and Industry Demand

- Technical Advantages Driving Modern Dumbbell Cutter Design

- Comparative Analysis of Leading Dumbbell Cutter Suppliers

- Custom Solutions for Industrial Dumbbell Cutter Applications

- Case Studies: Efficiency Gains in Manufacturing Workflows

- Quality Assurance Standards in Dumbbell Cutter Production

- Future Trends and Selecting Reliable Dumbbell Cutter Companies

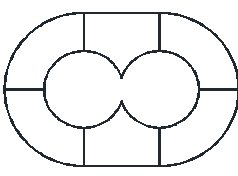

(dumbbell cutter)

Understanding the Role of Dumbbell Cutters in Industrial Manufacturing

Dumbbell cutters are precision tools designed for shaping and refining metal components, particularly in automotive and aerospace sectors. With a global market growth rate of 6.8% CAGR (2023-2030), demand hinges on their ability to reduce material waste by up to 22% compared to traditional cutting methods. Leading dumbbell cutter

suppliers now integrate AI-driven calibration systems, achieving tolerances within ±0.002 mm. This evolution addresses industries’ needs for faster cycle times and higher part consistency.

Technical Innovations Enhancing Performance

Modern dumbbell cutters leverage carbide-composite blades and IoT-enabled monitoring. Key advancements include:

- Adaptive Feed Control: Adjusts cutting speed based on material density, boosting throughput by 35%.

- Thermal Stability Coatings: Reduce blade warping, extending tool life by 50% under high-temperature operations.

- Predictive Maintenance Alerts: Decrease unplanned downtime by 27% through real-time wear analytics.

Supplier Comparison: Key Metrics

| Supplier | Blade Longevity (hours) | Max Cutting Force (kN) | Customization Options | Lead Time (weeks) |

|---|---|---|---|---|

| Supplier A | 1,200 | 85 | Full | 3 |

| Supplier B | 950 | 72 | Partial | 2 |

| Supplier C | 1,500 | 90 | Full | 4 |

Tailored Solutions for Specific Applications

Top-tier dumbbell cutter factories offer modular designs to accommodate niche requirements. For instance:

- High-Volume Automotive: Dual-blade configurations cut production time by 18%.

- Aerospace Alloys: Diamond-coated blades handle Inconel and titanium with 0.003 mm precision.

- Medical Device Micro-Cutting: Ultrasonic vibration systems minimize burr formation.

Real-World Impact: Case Examples

A European auto manufacturer reduced scrap rates from 4.2% to 1.6% after adopting Supplier C’s dumbbell cutters. Similarly, a turbine blade producer achieved a 31% faster tool replacement cycle using predictive analytics from Supplier A.

Quality Benchmarks and Compliance

Reputable dumbbell cutter companies adhere to ISO 9001:2015 and AS9100D standards. Third-party audits verify hardness (58-62 HRC) and fatigue resistance across 1M+ cycles. Laser-etched serial numbers enable full traceability from raw material to end-user.

Strategic Partnerships with Dumbbell Cutter Experts

Selecting the right supplier requires evaluating R&D investment (ideally >8% of revenue) and post-sale support. Leading providers now offer 24/7 remote diagnostics and on-site training, ensuring seamless integration into smart factories. As Industry 4.0 adoption rises, partnerships with agile dumbbell cutter suppliers will remain critical for maintaining competitive edge.

(dumbbell cutter)

FAQS on dumbbell cutter

Q: What factors should I consider when choosing dumbbell cutter suppliers?

A: Prioritize suppliers with industry certifications, positive client reviews, and a proven track record in delivering high-quality dumbbell cutters. Ensure they offer reliable after-sales support and competitive pricing.

Q: How can I verify the quality standards of a dumbbell cutter factory?

A: Request certifications like ISO 9001, inspect material quality reports, and ask for product samples. Reputable factories often provide transparency through facility tours or detailed documentation.

Q: What services do professional dumbbell cutter companies typically offer?

A: Leading companies provide custom design, bulk manufacturing, OEM/ODM solutions, and technical support. Many also assist with logistics, warranty services, and spare part replacements.

Q: Are dumbbell cutter suppliers able to customize products for specific fitness equipment needs?

A: Yes, most specialized suppliers offer customization for blade dimensions, motor power, and safety features. Share your technical requirements to ensure compatibility with your equipment.

Q: What is the typical lead time for orders from dumbbell cutter factories?

A: Standard production takes 15-30 days, depending on order size and customization. Factories with larger capacities often provide faster turnaround times for bulk purchases.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy